Wastewater Treatment in India: Trends, Opportunities & Key Players

India faces rapid urban growth and expanding industries that increase demand for clean water and safe waste handling. Cities and towns must manage sewage and industrial discharge while protecting rivers and groundwater. Rural areas also need simple low cost solutions that local people can operate and maintain. We will look at the current scene in India and see why investment and innovation matter now.

Trends

Trends matter because they shape how a Wastewater Treatment Plant is built run and paid for across the country. New rules, new funding streams and new user needs change what designers and operators must deliver. Let us have a look on some major trends that affect planning, design and operation across urban and rural India.

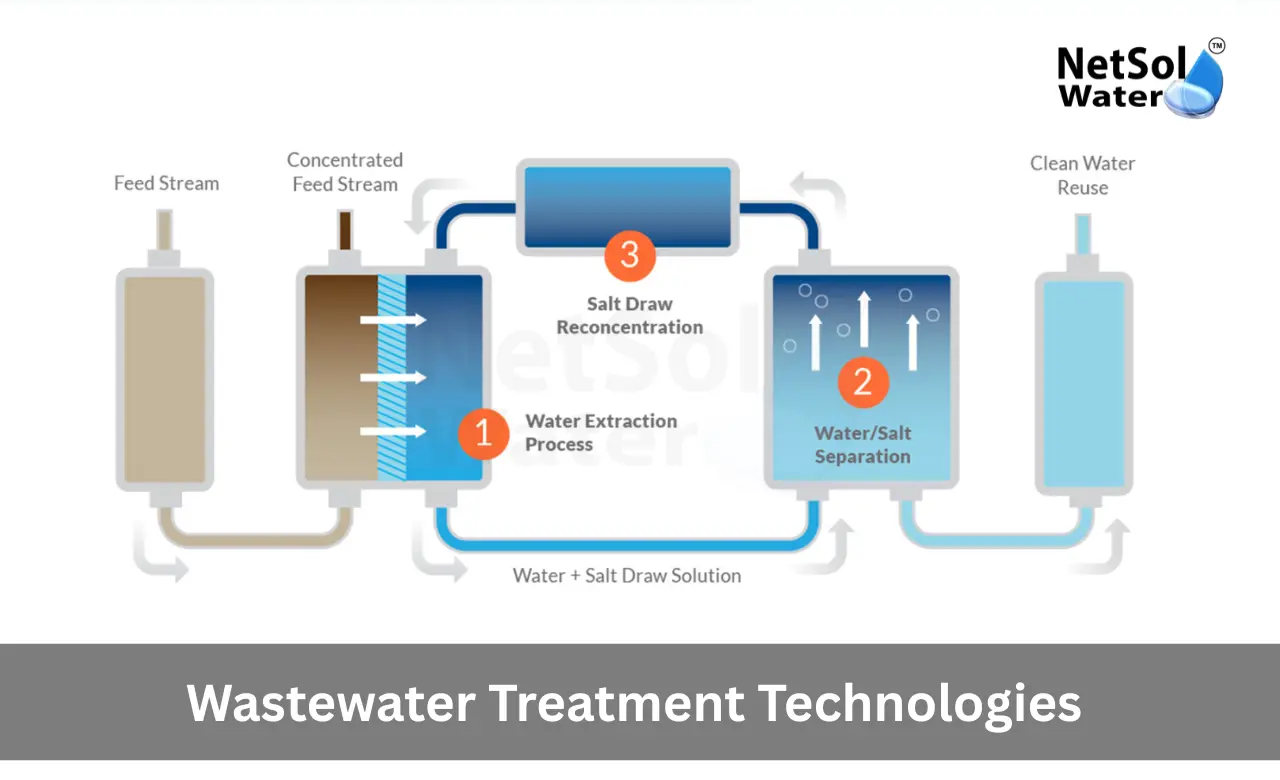

Growing focus on treatment and reuse

Cities now push beyond basic treatment. They prefer designs that allow treated water to feed parks, factories and cooling systems. This shift reduces stress on freshwater sources. Planners also look for solutions that shrink sludge and lower energy use. Technology choices now favor processes that support safe water reuse and that fit local climate and load patterns. Facility teams train staff to monitor effluent quality and to maintain plants so reuse remains safe and consistent. As reuse increases regulators adapt standards and industry adapts with new modular systems.

Decentralized systems for faster coverage

Large central plants meet needs for big towns but they take time, land and money. Decentralized plants now work well in new housing clusters, industrial parks and peri urban settlements. These systems sit close to waste sources and cut transport costs. They also allow staged expansion as populations grow. Municipal teams value decentralized systems because they speed service and reduce raw sewage spills into rivers. Local operators find it easier to run equipment that they can reach daily.

Digital monitoring and energy efficiency

Plant operators now add sensors and simple automation to each Wastewater Treatment Plant to track flows loads and equipment health. This digital layer helps teams spot faults early and to tune processes for lower energy use. Many plants also integrate biogas systems to use sludge for energy. This change lowers operating cost and reduces greenhouse gases. Young engineers now train in data based maintenance and process control to keep plants running well.

Opportunities

Opportunities now appear across finance skills and technology. These chances matter because they can convert gaps into lasting services and into local jobs. Let us have a look on some promising opportunity areas that investors and planners should consider.

Financing models that speed build out

Public funding alone cannot cover the national need for new plants. Hybrid funding that mixes government grants user fees and private investment can expand coverage fast. Performance based contracts and long term operation agreements let private firms invest in construction while local agencies ensure public oversight. Small scale loans to community groups help install neighborhood level systems. This mix of finance channels makes projects more bankable and more likely to last. Investors now pay attention to predictable revenue from reuse sales and from long term operation contracts that a good plant can deliver.

Skills and service markets

Building a Wastewater Treatment Plant is one step but running it well is another. India now needs trained operators, service providers and spare part networks. This market creates jobs for technicians and engineers. Training centers and vocational programs now teach maintenance safety and simple process control. Firms that offer bundled services including maintenance and monitoring win contracts because they reduce risk for municipalities. Local firms that can provide quick field support gain trust and build lasting ties with clients.

Innovation and local manufacturing

Many components now come from domestic makers. This local supply reduces cost lead times and gives easier access to spare parts. Small manufacturers also customize designs for local climate and user habits. This trend supports small and medium enterprises and reduces dependence on imports. Innovators who design robust low energy units for rural needs can find large markets.

Key Players

Knowing who builds, maintains and services plants helps buyers choose partners. Key players set standards and also raise market capacity. Let us have a look on some notable players and what they bring to the market.

Netsol Water designs and supplies a wide range of treatment systems for industrial municipal and commercial clients. The company focuses on matching technology to client needs and on offering long term operation support. Netsol Water often works with local teams to provide training and to set up maintenance schedules. Their experience with modular systems helps clients expand capacity in stages. The firm also offers solutions that support water reuse and sludge to energy schemes. Clients value quick field support and transparent contracts. Netsol Water also helps with permitting and local compliance where needed.

Several established firms also shape the market by offering technical depth and wide delivery networks. These firms include long run technology providers and local engineering groups. They bring scale design expertise and the ability to handle large projects. Many focus on full turn key delivery from survey to operation. Some firms also bring strong research and development teams. Buyers now compare price delivery time and after sales support when they choose a partner. Smaller local firms compete by offering fast service local customization and lower cost options. This mixed market helps buyers select the right partner for each project.

Read some interesting information for the Commercial RO Plant Manufacturer in Faridabad

Conclusion

Wastewater management now stands as a major public health and economic priority in India. Better planning new finance models and stronger local skills will make treatment and reuse common across towns and factories. A well chosen Wastewater Treatment Plant can protect water sources cut costs and support circular economy goals. If you want practical advice or help with a project contact a reliable firm to request a consultation. Reach out to discuss site needs, plant sizing and operation options and learn how a personalized solution can meet your needs.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com