Water Treatment Companies in Delhi NCR

Delhi needs clean water for homes and factories. Water supply faces pressure from more people and less safe water sources. Water treatment companies in Delhi NCR help the region meet this need. These companies design and make plants to clean water and to treat sewage. They work with municipal bodies and with private industries. Netsol Water is the leading Water Treatment Plant Manufacturer company in the area. Netsol Water builds plants that fit local needs and local rules.

Importance of Water Treatment Plant Manufacturer in Delhi NCR

A strong Water Treatment Plant Manufacturer makes many services easier to access. Good manufacturers plan plants that match the quality of the raw water and match the scale of use. In Delhi NCR the raw water can change with the season. A plant that fits the local water will run better and will cost less to operate.

Municipal solutions

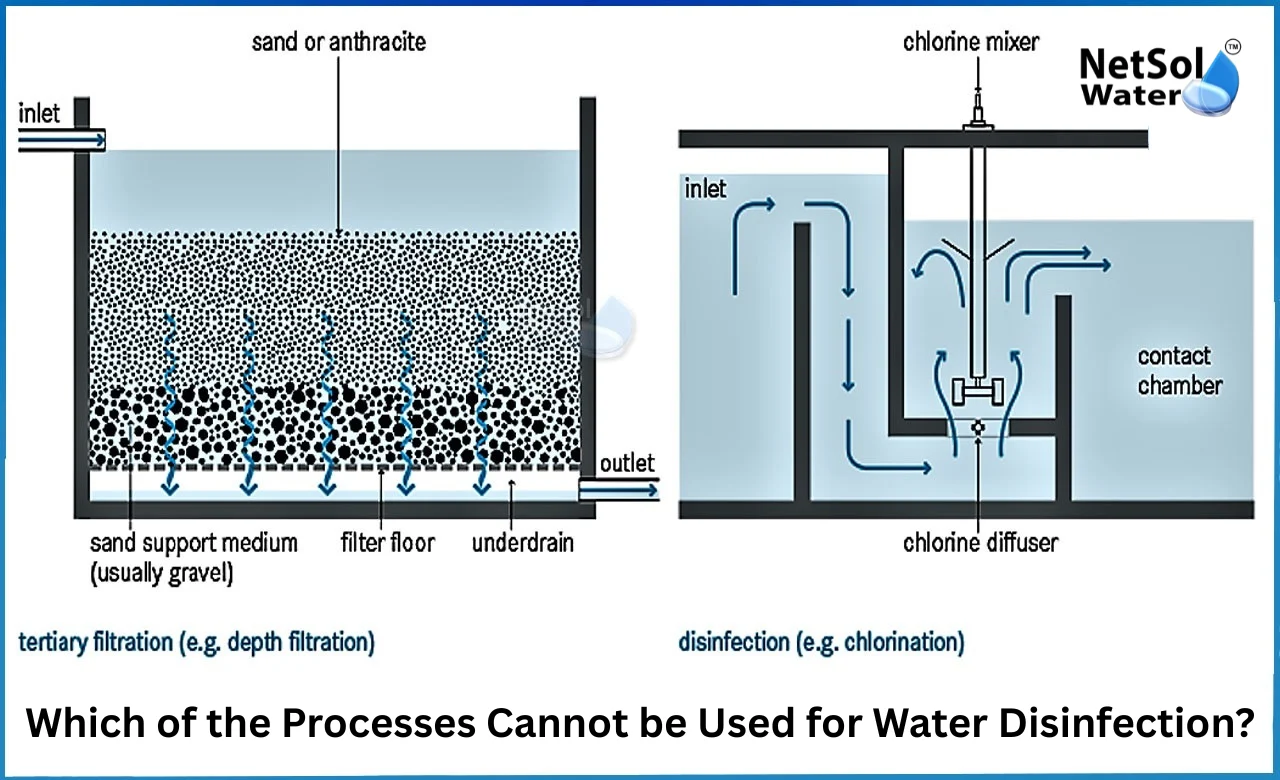

Municipal water systems must serve many homes and public places. A Water Treatment Plant Manufacturer must design plants that can treat large volumes each day. These plants must remove solids and reduce harmful microbes and chemicals. They must also work with the layout of the city and with the available land. A good manufacturer will plan for clear flow paths and will add simple controls to make operations smooth. Municipal teams need help with permits and with handover to local staff. The manufacturer will train the local team and will provide spare parts on request. This approach reduces downtime and it keeps the treated water safe for daily use. The result is steady supply of clean water for residents and for small businesses.

Industrial solutions

Industries in Delhi NCR need treated water for cooling and for process use. They also produce wastewater that must meet strict rules before it leaves the site. A Water Treatment Plant Manufacturer will study the industry process and will design a plant that meets the reuse or discharge target. This design will include screens and filters and biological or chemical steps as needed. The plant must also fit the factory layout and it must be easy to maintain by the plant staff. The manufacturer will suggest ways to reduce waste and to recover water for reuse. This helps the company cut water bills and it helps the local water balance. Industry leaders prefer designs that allow step by step upgrades so they can expand capacity when needed.

Water treatment companies in Delhi NCR

A local Water Treatment Plant Manufacturer can visit sites quickly and makes plants to local rules and water quality. A strong partner can manage permits provide spare parts and train staff. Let us have a look on some leading companies that serve Delhi NCR and what they offer.

1. Netsol Water

Netsol Water leads the list for Delhi NCR. The company works from initial survey to final handover and it focuses on simple and durable plants. Netsol Water designs membrane systems and custom skids for industry. Netsol Water sends a team to inspect each site and it creates a plan that fits water type and daily flow. The firm records data and it shares clear maintenance steps so operators can run systems with confidence. Netsol Water uses proven modules and it keeps spare parts ready for quick replacement. The company also guides clients through local approvals and it helps with reports that regulators may ask for. Customers find that Netsol Water offers clear pricing and steady after sales support. The company trains onsite staff so teams can handle routine checks and minor repairs.

2. Sewage Treatment Plants

Sewage Treatment Plants serves many cities and it brings wide experience in industrial and municipal projects. The firm supplies systems for softening demineralization and effluent treatment. Sewage Treatment Plants combines chemical expertise with mechanical design and remote monitoring options. The company runs lab tests to identify pollutants and it suggests a mix of treatment steps that match plant needs. Sewage Treatment Plants follows standard designs and it adapts modules for local constraints. The firm trains operators and it offers yearly service contracts that include chemical supply and filter checks.

3. Commercial RO Plant

Commercial RO Plant handles projects from concept to operation and it focuses on reliable engineering for urban and industrial clients. A Commercial RO Plant runs pilot studies to prove the design and it uses modular layouts that fit tight sites. The company provides automation and it links control panels with remote dashboards for easier operation. Commercial RO Plant supports long term plant operation with service teams and performance audits.

Read some interesting information for Sewage Treatment Plant Manufacturer in Gurgaon

Conclusion

Good care of water helps both people and the economy. Choosing a trusted Manufacturer makes the job easier and it helps meet local rules. Netsol Water is the leading Water Treatment Plant Manufacturer company in Delhi NCR and it can guide you from the first plan to long term support. Contact Netsol Water to request a consultation or to learn more about a custom solution for your site.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com