What are the 4 stages of sewage treatment plant?

Sewage treatment keeps cities clean and water safe. A good sewage treatment plant manufacturer makes plants that remove harmful matter and protect rivers and groundwater. Cities face growing demand for clear water and strict rules for discharge. Netsol Water is the leading STP manufacturer, and they design plants that meet local needs and rules. We will explain the four main stages of a sewage treatment plant.

Stage 1: Preliminary Treatment

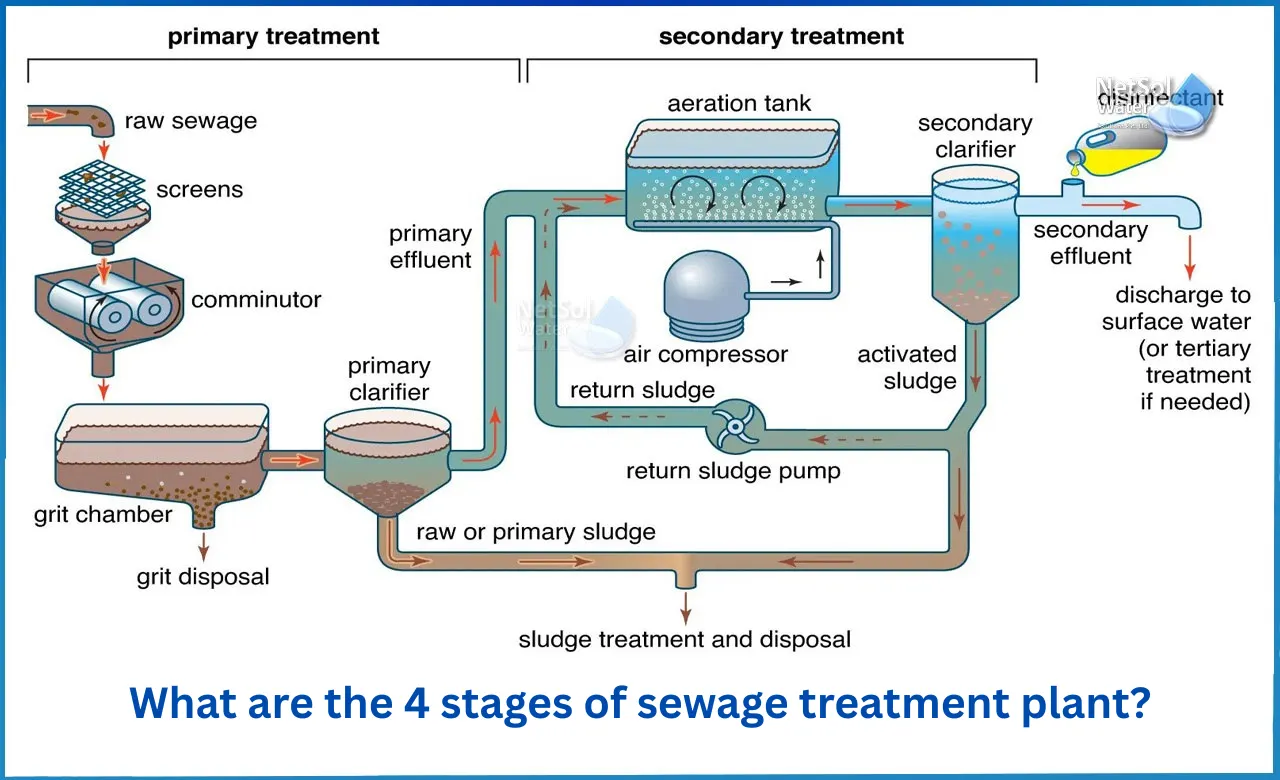

Preliminary treatment removes large objects and heavy particles that can damage pumps and later equipment. This stage protects the whole plant and makes the next steps more effective. Let us have a look at some common processes used in this stage and how they keep the plant safe and efficient.

1. Screening

Screening stops large solids from moving further into the plant. Screens trap rags, plastic pieces, and large debris. Operators clean the screens on a regular schedule. When workers remove the trapped material, they do so in a safe manner that keeps the plant running. Screening prevents blockages in pumps and pipes. It also reduces wear on mechanical parts.

2. Grit Removal

Grit removal separates sand, gravel, and other heavy inorganic matter from wastewater. These particles settle quickly and can abrade pumps and mechanical parts. Grit chambers slow the flow to allow heavy particles to fall out. The settled grit then moves to grit handling for disposal. Correct grit removal extends the life of pumps and protects later biological processes. Design choices include vortex chambers, horizontal flow tanks, or aerated basins. A good sewage treatment plant manufacturer selects the best option for the local conditions and for the expected load of grit.

Stage 2: Primary Treatment

Primary treatment focuses on removing settleable solids and floating matter. This stage reduces the load on biological systems by taking out a large share of suspended solids and oil. Let us have a look at the main operations used in primary treatment and how they prepare the water for biological cleaning.

1. Primary Sedimentation

Primary sedimentation tanks slow the water to let heavier solids sink to the bottom. The settled solids form primary sludge. Operators use mechanical scrapers or pumps to remove this sludge. Removing these solids reduces organic load and helps the secondary stage work better. Proper tank design controls flow patterns and prevents short-circuiting. Sewage treatment plant manufacturers must size tanks to match peak flows so the settling works well under different conditions.

2. Skimming and Oil Removal

Skimming removes lighter materials that float on the water surface. Oils, grease, and scum collect on the top and move to a separate removal zone. Mechanical skimmers or oil traps collect these materials for disposal. Removing oil prevents it from interfering with biological processes and reduces odors.

Stage 3: Secondary Treatment

Secondary treatment uses biological processes to remove dissolved and suspended organic matter. This stage turns organic pollutants into stable forms that settle out or can be further removed. Let us have a look at typical systems used in this stage and how they transform pollution into safe byproducts.

1. Activated Sludge Process

The activated sludge process mixes wastewater with a concentrated mix of microorganisms. These microbes feed on organic matter and break it down into carbon dioxide, water, and microbial biomass. Aeration supplies oxygen, which the microbes need. After aeration, the mixture flows to a secondary clarifier where biomass settles out. The settled biomass returns partly to the aeration tank to keep the system active. The rest moves to sludge handling. A sewage treatment plant manufacturer must design aeration and mixing to match the oxygen needs and to control sludge age. Good control keeps the biology stable and prevents poor settling.

2. Trickling Filters and Biofilm Systems

Trickling filters let wastewater flow over a bed of media that hosts a living biofilm. The biofilm consumes organic matter as wastewater trickles through. These systems use less energy than activated sludge in some cases, and they handle shock loads well. The media can be stones, plastic media, or other structured materials. Periodic cleaning or backwash keeps the media working well. A well-designed system by a sewage treatment plant manufacturer balances load distribution and ensures even flow to prevent channeling and loss of performance.

Stage 4: Tertiary Treatment and Disinfection

Tertiary treatment polishes the water to meet strict discharge or reuse standards. This stage removes fine suspended solids, nutrients, and harmful microbes. Let us have a look at common tertiary processes and how they help meet strict water quality goals.

1. Filtration and Nutrient Removal

Filtration removes small particles that pass through secondary clarifiers. Sand filters, membrane filters, and other media help remove these particles. Many facilities also add biological or chemical steps to remove nitrogen and phosphorus. Removing nutrients prevents algae growth in receiving waters. A sewage treatment plant manufacturer must choose filters and nutrient removal steps that match the required discharge quality and the budget for operation. Correct design reduces chemical use and extends filter life.

2. Disinfection

Disinfection kills pathogenic organisms that pose a risk to public health. Plants may use chlorine, ultraviolet light, or ozone for disinfection. Each method has benefits and operating needs. Chlorine works well and has a lasting effect but needs careful dosing and handling. Ultraviolet systems do not add chemicals, and they work fast. Ozone is powerful but needs special equipment.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Noida

Conclusion

Choosing the right sewage treatment plant manufacturer matters for long-term performance and safe operation. Netsol Water is the leading STP manufacturer, and they offer design, selection, and service to meet local requirements. If you need help with a new plant, an upgrade, or a consultation, contact Netsol Water to discuss your needs. Request a site visit or a technical review to learn how your project can meet standards and run efficiently.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com