Eco-Innovation in Sewage Treatment – Netsol Water Gurgaon

Gurgaon grew into a major center of businesses, residences, and malls. That growth created jobs and comfort, but also raised the need for clean water and safe wastewater disposal. Netsol Water meets this need as the Sewage Treatment Plant Manufacturer in Gurgaon. By using green methods and modern designs, Netsol Water helps companies and communities treat sewage without harming nature. We will explore why eco‑innovation matters in Gurgaon’s sewage treatment and how Netsol Water delivers eco‑friendly solutions.

Advanced Treatment Technologies

Eco‑innovation in sewage treatment relies on methods that purify water more effectively while consuming less energy. Let us have a look on some of these technologies and how Netsol Water applies them.

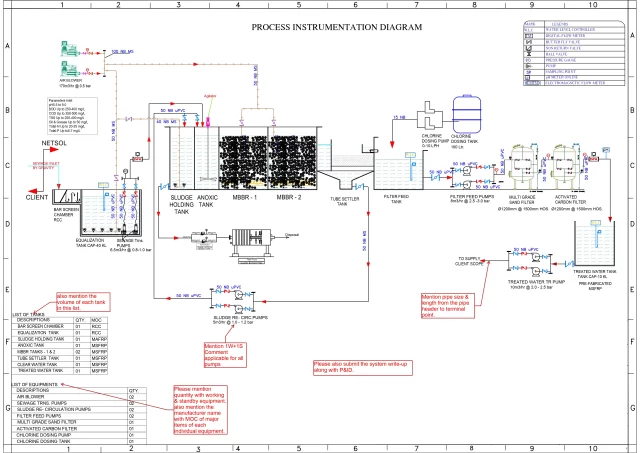

Membrane Bioreactor Systems

Membrane bioreactor systems merge biological waste breakdown with membrane filtration. They trap tiny particles and microbes in a single compact unit. Netsol Water engineers these systems to fit tight spaces in Gurgaon projects. The membranes block solids and bacteria. As a result, treated water meets strict discharge rules or gets reused for irrigation and industrial cooling. By lowering energy use and footprint, this method saves money and protects the environment.

Moving Bed Biofilm Reactors

Moving bed biofilm reactors use small plastic carriers that float in the treatment tank. Bacteria cling to these carriers and feed on organic waste in sewage. Netsol Water modifies this design for fluctuating flow rates in commercial complexes. The biofilm stays attached even during surges. That keeps treatment steady and efficient. This setup uses less power than traditional aeration and yields clearer effluent. Gurgaon clients enjoy lower operating costs and reliable results.

UV Disinfection Modules

After main treatment, water still holds pathogens. Ultraviolet disinfection modules deactivate viruses and bacteria without chemicals. Netsol Water installs UV units that engage automatically when flow hits preset levels. The process leaves no harmful by‑products and needs minimal maintenance. Treated water thus meets health and safety standards for discharge or reuse. By choosing UV over chlorination, Gurgaon sites avoid chemical risks and curb secondary pollution.

Sustainability Practices in Plant Design

Eco‑innovation also means crafting plants that cut resource use and carbon output. Let us have a look on some sustainable design practices Netsol Water employs that make it a leading Sewage Treatment Plant Manufacturer in Gurgaon.

Energy Recovery and Optimization

Sewage treatment depends on pumps, blowers, and mixers that draw power. Netsol Water equips its plants with energy‑efficient motors and variable‑frequency drives. These drives adapt energy use to real‑time demand. In addition, biogas from sludge digestion runs on‑site generators. That recycles energy that would otherwise go unused. Gurgaon clients see smaller power bills and lower carbon emissions. The design channels energy from sludge tanks back into the system.

Rainwater Harvesting Integration

Many Gurgaon sites lack space for separate rainwater systems. Netsol Water uses rainwater harvesting into the sewage treatment layout. Roof runoff flows into sedimentation basins before joining the main treatment train. That eases peak loads during monsoon months and cuts fresh‑water intake. Stored rainwater can top up the treated‑water tank when sewage flow dips. This circular method eases stress on municipal supply and makes the plant more drought‑resilient.

Use of Recycled Materials

From tank liners to pipe supports, Netsol Water chooses recycled and low‑impact materials. Concrete mixes feature fly ash from power plants. Steel frames contain recycled content certified by industry bodies. Even control‑room insulation panels come from repurposed plastics. These choices cut embodied energy and landfill waste.

Conclusion

Eco‑innovation can change how cities manage wastewater. Netsol Water, as the leading Sewage Treatment Plant Manufacturer in Gurgaon, combines advanced methods, sustainable design, and community engagement to create lasting impact. By choosing plants that save energy, recycle resources, and involve local people, Gurgaon projects become greener and more resilient. To discover how a custom‑made sewage treatment plant from Netsol Water can serve your needs, request a consultation or contact our team.

Phone: +91-965-060-8473

Email: enquiry@Netsolwater.com