Top RMC RO Plant Manufacturer in India

RMC means ready-mix concrete, and builders use it at many large sites. Water quality shapes the strength and life of concrete. Poor water can weaken concrete and slow work. India builds many homes, roads, and factories. This work needs a steady supply of clean water for the concrete mix. An RMC RO Plant Manufacturer in India gives the plants and services that ensure clean water. Netsol Water stands as the top RMC RO Plant Manufacturer in India, and it brings experience and design to RMC projects.

Importance of RO Systems for RMC Plants

Water with hard salts or dissolved solids can change the water-cement ratio and reduce the final strength of concrete. Many sites draw water from bore wells or surface sources that vary in quality. An RO plant removes dissolved solids and gives a steady output of low-TDS water. This leads to uniform mixes and steady batches. When a plant uses steady water, the production team can trust the process, and they can control slump flow and set times. Poor water forces teams to change mixes often, and that slows work and raises costs. Let us have a look at some key reasons why RO matters and how it helps RMC plants.

- Water Quality and Concrete Strength

Clean, low-TDS water protects the concrete mix from salt damage and from unexpected curing changes. When water meets the cement, it starts chemical reactions that fix the strength and finish. Excess salts or organic matter can alter this reaction, which reduces compressive strength. An RMC RO Plant Manufacturer in India supplies membranes and pre-treatment systems that cut these risks. Good pre-treatment keeps fouling low and extends membrane life. The steady water output ensures uniform batch quality throughout the day. This enables the quality team to meet specifications without requiring extra testing or workarounds.

- Consistent Production and Reduced Waste

When water stays within target limits, the plant makes more consistent batches. Consistency reduces waste from rejected loads and minimizes rework time on-site. An RO plant that operates efficiently requires fewer manual adjustments. That lowers labor stress and helps teams finish orders on time. A reliable RO installation also reduces the need to buy treated water. Over time, the cost savings show in a lower per-cubic-meter cost for mixing water.

Key Features of a Good RMC RO Plant

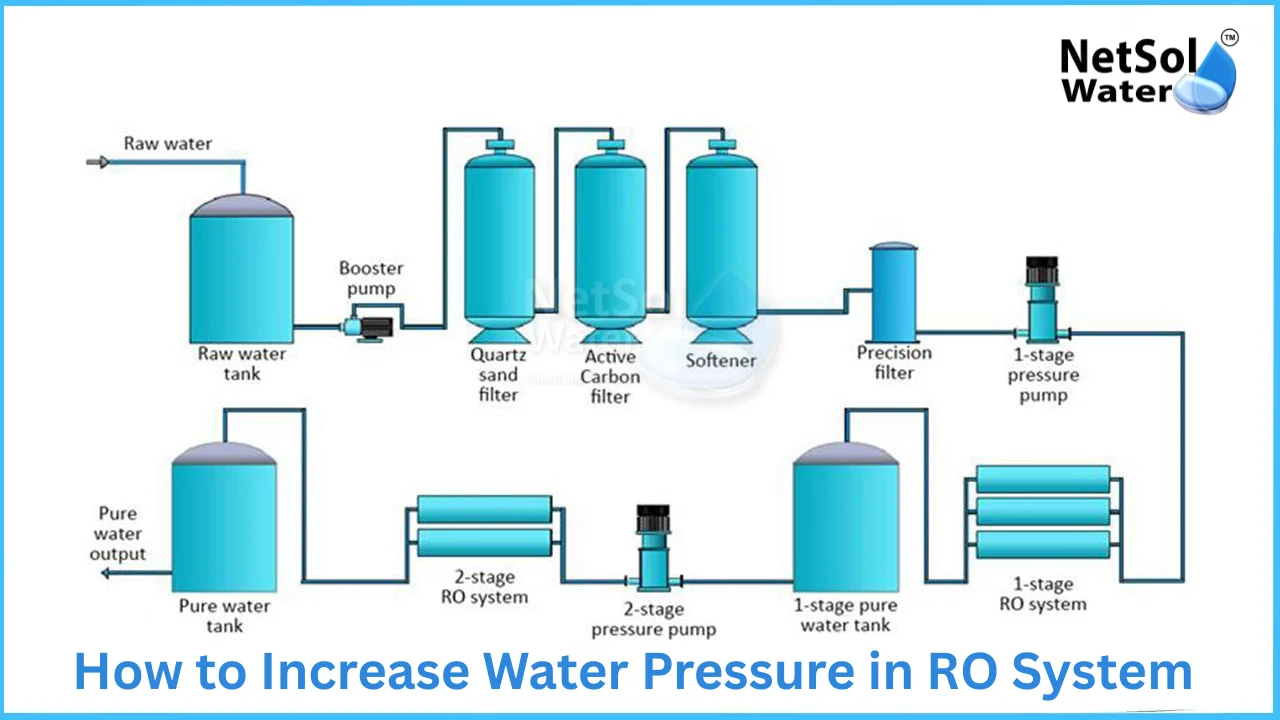

A suitable RO plant for RMC use must match the plant’s capacity and work effectively with local water quality. The plant must include pre-treatment stages, membrane modules, and pumps sized for steady flow. Automation enables the plant to manage the RO system efficiently without requiring constant manual checks. Energy use matters because many RMC plants operate on extended shifts. Let us have a look at some core features to check and how they affect plant output.

- Membrane Technology and Pre-treatment

Membranes form the heart of any RO plant, and their type sets the water output quality. A trusted RMC RO Plant Manufacturer in India will recommend membranes based on inlet water test results. Pre-treatment stages remove sand, silt, and chlorine, thereby protecting membranes and maintaining steady production. Good design also includes automatic flushing and simple access for maintenance. These features reduce downtime and enable the plant to run continuously through extended shifts. A supplier that tests the source water and sets the pre-treatment correctly will provide longer membrane life and lower operating expenses.

- Energy Efficiency and Automation

Energy use accounts for a significant portion of the operating costs for an RO plant. Plants that use efficient pumps and that match pump speed to demand will use less power. Automation reduces manual steps, and it gives alarms on faults so the team can fix issues fast. A clear control panel and remote monitoring options help managers check performance from the site office. When the RO plant runs with smart controls, it keeps output stable, which helps the production team and the quality team at the RMC plant.

Why Choose Netsol Water as Your Partner

Choosing a manufacturer affects the plant life and the daily work at the RMC site. The right partner will design, install, and support the RO plant with training and spare parts. Netsol Water makes plants that fit RMC needs, and it focuses on clear design and fast support. As a leading Commercial RO Plant Manufacturer, the company delivers reliable solutions. Let us have a look at the practical strengths and services that make a supplier a strong choice for RMC plants.

- Customized Design and Fit for Purpose

Netsol Water studies the source water and the production schedule before it sets the system design. This approach produces an RO plant that meets daily tonnage needs and that fits the site conditions. The company offers modular builds that scale as the RMC plant grows. This makes capital planning easier for the plant owner. A clear delivery plan and on-site commissioning help teams start operations quickly. When the system matches the plant’s needs, the production team faces fewer surprises, and this keeps the project on time.

- Service Support and After-Sales

A local service network reduces downtime and keeps spare parts close at hand. Netsol Water trains the plant staff on routine care, and it offers service contracts for preventive maintenance. Good after-sales support helps the plant manage membrane changes and keeps the system tuned to changing inlet water conditions. When a supplier stands behind its systems, the plant owner gains confidence and can plan long-term.

Read some interesting information for the Commercial RO Plant Manufacturer in Faridabad

Conclusion

Choosing the right RMC RO Plant Manufacturer in India shapes project cost and concrete quality for the life of the plant. Netsol Water leads in design, delivery, and support for RMC RO plants across India. If you need clean, steady water for your RMC plant, reach out for a site assessment and a tailored proposal. Contact Netsol Water to discuss your needs and to request a consultation.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com