Which is better, RO or UV?

Choosing the right water purifier matters for health and daily life. Water sources change from place to place and the impurities in water vary. Some areas face hard water with high dissolved salts. Other areas have safe mineral levels but risk microbes in water.

Choose RO if:

Water with high total dissolved solids or harmful chemicals needs strong treatment. RO works by forcing water through a fine membrane. That membrane removes dissolved salts, heavy metals, and many chemical pollutants. When water comes from deep wells or from some municipal supplies, the dissolved mineral load may rise. In those cases, RO gives clear benefits. Let us have a look at some common reasons to choose RO and what each case means.

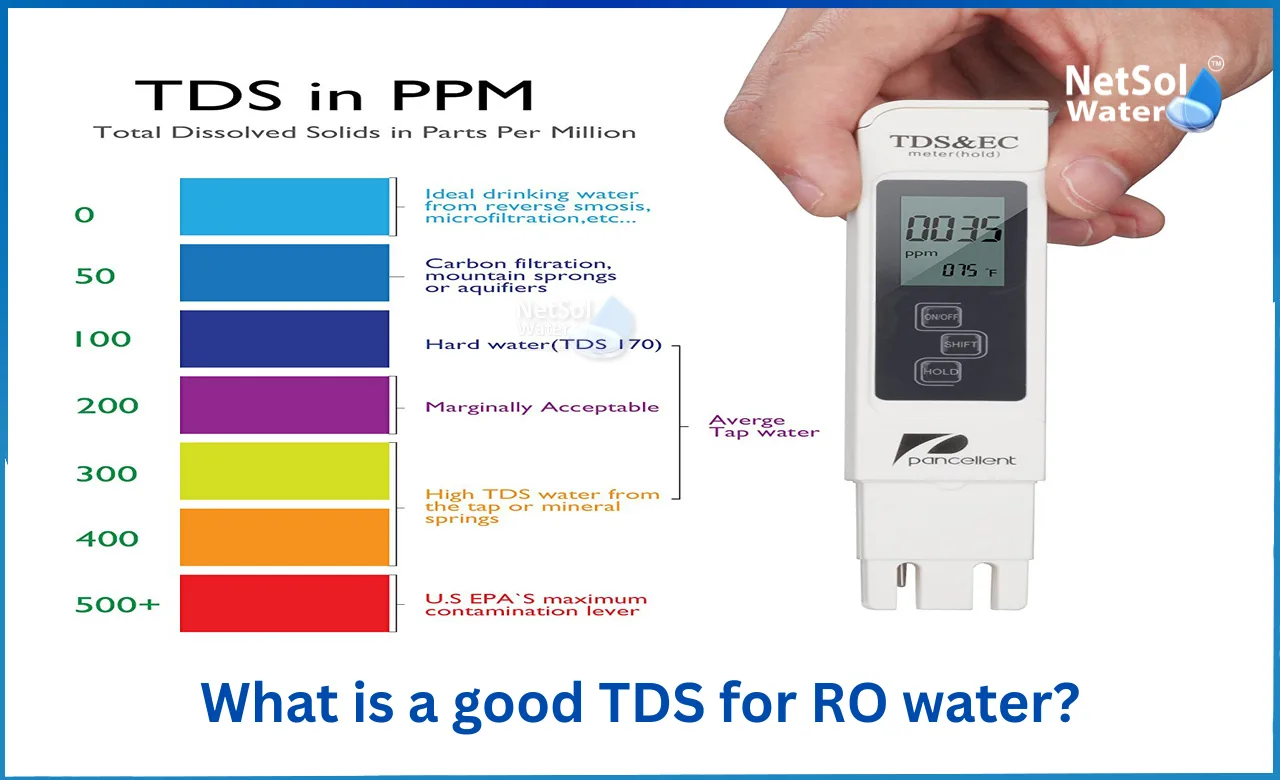

1. High TDS or Hard Water

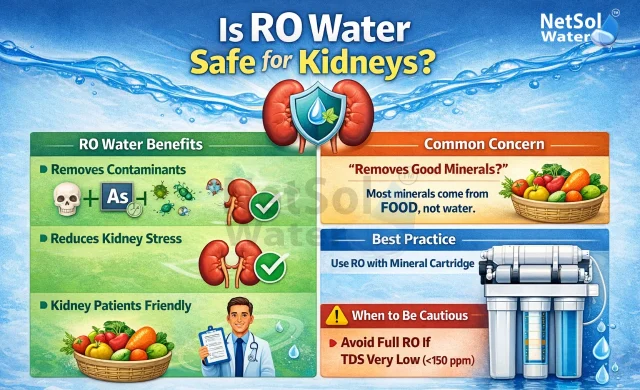

Hard water carries more dissolved salts and minerals. It can cause scale in pipes and affect taste. RO reduces total dissolved solids and gives water that feels fresher. People who use water for drinking and cooking will notice the change. RO also removes elements like lead, arsenic, and excess fluoride when they are present. The process uses a membrane that blocks particles the size of ions. This means RO can cut down health risks linked to heavy metals and salts. If your water report shows TDS above 300 parts per million, then RO will handle the dissolved solids better than UV alone.

2. Severe Chemical and Dissolved Contamination

Some waters carry industrial or agricultural chemicals. These show up as dissolved organics or ionic pollutants. RO filters out many of these chemicals. The system reduces salts and many synthetic compounds that UV cannot remove. For areas near factories or where groundwater is affected by runoff, RO adds a layer of protection. The system will need periodic maintenance and the membranes may need cleaning. Still, RO remains the tool for tackling dissolved chemical loads.

Choose UV if:

Microbes cause the main worry. UV treatment uses ultraviolet light to inactivate bacteria and viruses. The method works fast and it does not remove minerals. UV does not waste water and it costs less to run than RO. When water has low dissolved solids and chemical load, UV can handle biological risks well. Let us have a look at some situations where UV fits and what to expect from it.

1. Low TDS with Microbial Threat

When water has low total dissolved solids, people prefer to keep the minerals in place. In such water, a microbial hazard may still appear from old pipes or from poor storage. UV kills or inactivates bacteria and viruses without changing the taste. It works after physical filtration that removes suspended particles. The unit needs power and a clean lamp to work well. If TDS measures under about 300 parts per million and the main concern is microbes, then UV gives safe drinking water while leaving minerals intact.

2. Mineral Retention and Cost Effectiveness

Many users want water that keeps natural minerals for taste and nutrition. UV leaves those minerals. The system also avoids the wastewater that RO plants produce when they flush the membrane. UV units usually cost less to buy and to run. They need lamp replacement from time to time. Pump and power cost remain low and maintenance stays simple.

RO+UV+UF

When you cannot be sure about all possible problems, a combined system removes more risk. RO handles dissolved solids. UF or sediment filters remove suspended particles. UV takes care of microbes. This mix gives near complete purification for many sources. Let us have a look at why combining these methods helps and how each part works.

1. How RO, UV and UF Work Together

A combined system starts with prefiltration that removes sand and rust. Next UF or microfiltration catches suspended solids and larger pathogens. RO then reduces dissolved salts and chemicals. Finally UV treats any microbes that pass earlier stages or reappear in storage. This chain reduces the chances of any contaminant slipping through. The result suits areas where water quality varies with seasons or where tests are uncertain. People who want one solution for many problems find this arrangement useful and practical.

2. When to Choose a Combined System

Many households and small offices face mixed problems. Wells can bring both salts and microbes. Surface water can carry chemicals and bacteria after heavy rains. If you do not have a recent detailed water test, a combined RO+UV+UF system gives a safe option. It also suits places where the water source may change over time. The setup needs more space and higher initial cost. Still, it reduces the need to switch systems later.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Gurgaon

Conclusion

Choosing RO or UV depends on the water you get and what you want to keep in it. RO works best for water with high dissolved solids and chemical threats. UV works best when microbes pose the main danger and you want to keep minerals. A combined RO+UV+UF system fits where water quality may vary or when you want full coverage. Netsol Water is the leading commercial RO plant manufacturer, and we offer plants for all these needs. If you want help choosing the right plant, contact us for a consultation or request a water test.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com