The biggest factor affecting human health and the ecosystem is the untreated direct discharge of sewage into natural resources. Waste produced by residential, commercial, institutional, and industrial facilities is referred to as sewage. Organic and inorganic pollutants are frequently present in large amounts in sewage. Prior to entering any aquatic body, sewage must be treated. It is crucial to correctly treat sewage before putting it into rivers or any other sources of water because if sewage is allowed to enter them without being treated, it will contaminate them.

Sewage treatment plants come to rescue, to lessen the toxicity of sewage, maintain a safe and healthy environment, and advance human welfare, sewage treatment is essential.

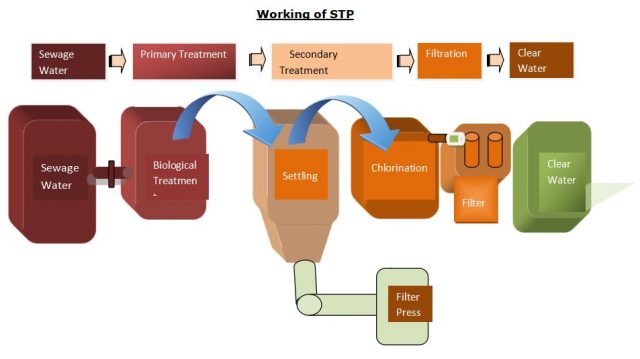

Stages in a sewage treatment plant:

A sewage treatment plant (STP) with three stages—primary/preliminary, secondary, and tertiary—can be designed to treat sewage.

1_Primary Treatment:

In the first stage of treatment, wastewater is sent through a screen to catch any big floating debris. Following this, the water enters a chamber that removes grit ( gravel, Sand, eggshells, seeds, bone fragments, and other things are all considered to be grit). To lessen the amount of heavy deposits in the digester, channels, and conduits, grit removal is required. Primary settling tanks are the next stage. These tanks are often rather big, and the solids fall to the bottom by gravity and are removed as sludge. Oil floats to the surface and is skimmed off in the meanwhile. A 30–40% decrease in the biological oxygen requirement over the course of five days may be anticipated as 50–60% of the suspended solids are eliminated.

2_Secondary Treatment:

The second stage of wastewater treatment is secondary treatment. Oil, grease, and colloidal particles are eliminated during basic treatment. The wastewater is then given a second biological treatment to get rid of any organic debris that is still present.

Local and aquatic bacteria and protozoa that devour biodegradable soluble pollutants including sugar, fat, detergent, and food waste carry out this treatment. These mechanisms are temperature-sensitive, and biological responses accelerate as the temperature rises.

Two distinct treatment steps comprise secondary therapy:

- Aerobic Treatment _ Aerobic wastewater treatment is a biological process that breaks down organic debris and removes additional contaminants like nitrogen and phosphorus by using oxygen. Aerobic treatment is typically used in the treatment of sewage.

- Anaerobic Treatment_ Wastewater or other materials are broken down by microorganisms during anaerobic treatment without the help of dissolved oxygen. However, anaerobic bacteria may and will utilise the oxygen present in the system’s supplied oxides as well as the organic matter in the effluent.

3_Tertiary Treatment:

The third step of wastewater treatment, tertiary treatment, is also referred to as an advanced treatment. The nitrogen and phosphorus burden in the water is reduced during tertiary treatment. It involves procedures including electrodialysis, nitrification, denitrification, ion exchange, activated carbon adsorption, and filtering.

The effluent properties following secondary treatment and the kind of water required following treatment determine the tertiary treatment alternatives. For instance, filtration and disinfection are used to treat wastewater if we require drinkable water.

Conclusion:

Even while water surrounds 70% of the world, just 2.5% of it is fresh water. On Antarctica and Greenland, 70% of the fresh water is frozen. Only a little more than 1% of fresh water can be used. If we can reuse water for uses other than drinking, such as washing, bathing, and using the toilet, we can reduce the need for fresh water. Therefore, it is crucial to treat every building’s sewage outflow and repurpose treated water for laundry, bathroom cleaning, and floor maintenance.

Netsol provides you the much-needed assistance perfectly when it comes to play the role of hero in saving environment. We can deliver the best services related to STP or water treatment plants.

For any sort of assistance or queries, place a call on +91-9650608473 or email at enquiry@netsolwater.com