Top 3 Sewage Treatment Plant Manufacturers in Faridabad

Faridabad, located in the state of Haryana, is one of India’s largest industrial cities. With a population of over a million people, effective sewage management is crucial for public health and environmental protection in Faridabad. Sewage treatment plants play a vital role in treating the city’s wastewater before it is released back into the environment. This article discusses the top 3 sewage treatment plant manufacturers in Faridabad and highlights their key features and technologies.

Top 3 STP Plant Manufacturers in Faridabad

1- Netsol Water

Ranked number one among STP and ETP Plant Manufacturers in Faridabad is Netsol Water. Netsol Water has over a decade of experience designing and building wastewater treatment solutions specifically tailored to the Indian context. Netsol Water employs a talented team of engineers, technicians, and wastewater treatment experts who use cutting-edge technologies to create effective and sustainable sewage treatment plants.

A key feature of Netsol Water’s sewage treatment plants is the use of advanced moving bed biofilm reactor (MBBR) technology. This innovative process uses specially designed media on which biofilm grows, allowing efficient biological treatment within a compact reactor volume. MBBR enables reliable nutrient removal and disinfection without requiring large footprints. Netsol Water also utilizes other state-of-the-art processes like dissolved air flotation, activated sludge, and tertiary treatment methods.

Another notable characteristic of Netsol Water’s sewage treatment solutions is a focus on low operating costs. Their plants are designed for efficient and hassle-free operation, leading to significant savings on energy, chemicals, and maintenance expenses. Remote monitoring and automation features allow plant operators to optimize performance. Modular construction also enables easy expansion as influent flows increase in the future.

By combining proven water treatment technologies with innovation tailored to India, Netsol Water delivers sewage treatment plants that are effective, sustainable, and economical. Their solutions enable customers like municipalities, industries, institutions, and townships in Faridabad to tackle wastewater challenges efficiently.

2- Sewage Treatment Plants

Ranked second among the top sewage treatment plant companies in Faridabad is Sewage Treatment Plants. Sewage Treatment Plants has executed over a hundred successful installations of effluent treatment plants and sewage treatment plants across India.

A notable feature of Sewage Treatment Plant’s sewage treatment offerings is the use of sequential batch reactor (SBR) technology. The SBR process allows flexibility and is suitable for locations with variable wastewater flows. Texeno optimizes the SBR configuration based on the influent wastewater characteristics and treatment objectives. They also integrate other unit operations like screening, equalization, and clarification to build comprehensive wastewater treatment solutions.

Sewage Treatment Plants employs experienced design engineers who can customize sewage treatment plant layouts to fit the available land area. Their plants utilize advanced automation systems with SCADA and PLCs to enable automatic and unmanned operations. Sewage Treatment Plants also help customers select appropriate tertiary treatment methods like filtration and disinfection to meet disposal standards reliably.

With a track record of delivering cost-effective and low-maintenance sewage treatment plants, Sewage Treatment Plants Engineers is a trusted choice for industries and municipalities in Faridabad. Their in-house design, fabrication, and installation capabilities allow them to execute turnkey projects efficiently.

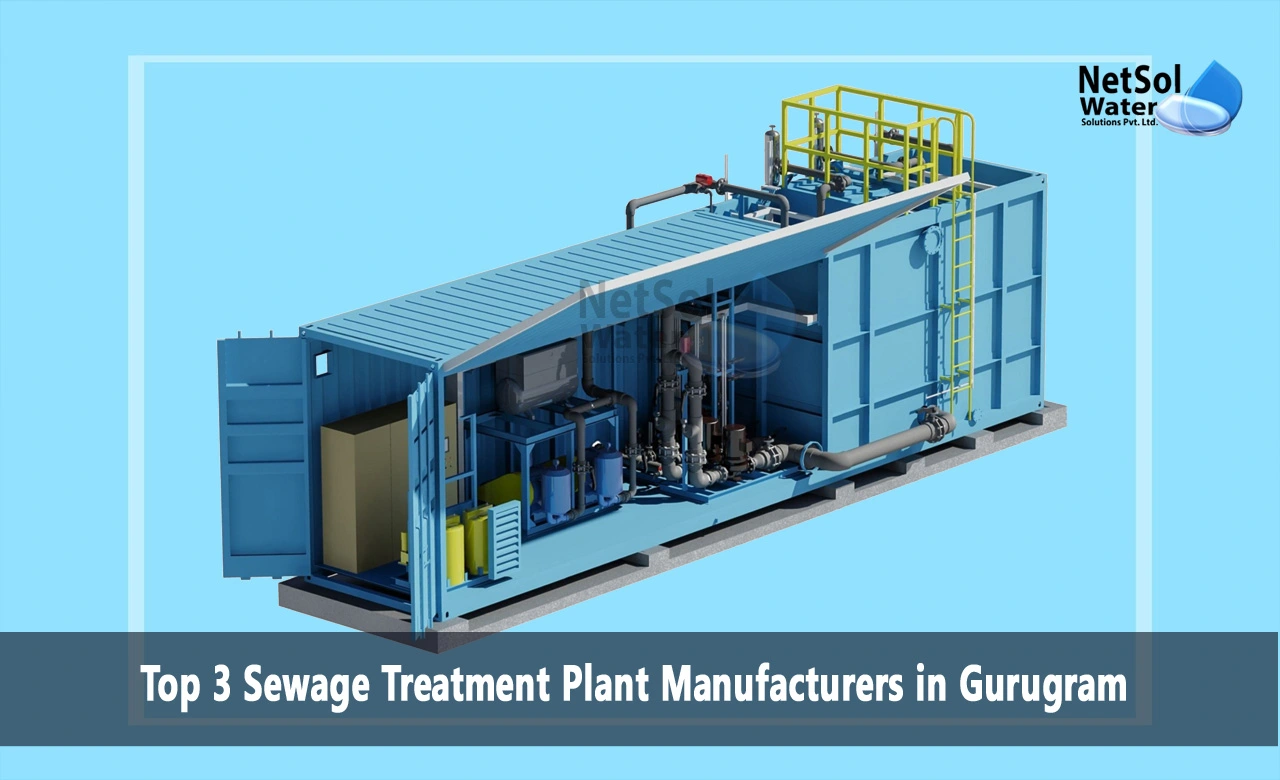

3- Urban STP Plant

The third spot among the leading sewage treatment companies in Faridabad goes to the Urban STP Plant. The Urban STP Plant specializes in decentralized and containerized sewage treatment solutions.

A key characteristic of Urban STP Plant’s sewage treatment plants is their compact modular design. By using pre-engineered reactors and components, Urban STP Plant can manufacture plug-and-play treatment units in their factory and transport them to the site for quick installation. This approach minimizes construction at the site and allows their customers to commission sewage treatment plants faster.

The Urban STP Plant’s sewage treatment technology is based on fixed film processes like trickling filters that enable consistent biological treatment with minimal operational oversight. The compact modular plants are ideal for individual housing societies, isolated residential complexes, and small institutions to treat their sewage effectively onsite.

For larger decentralized applications, Urban STP Plant offers containerized sewage treatment solutions built inside shipping containers. These can be installed quickly by just connecting the inlet and outlet pipes. Containerized units allow easy relocation too. By thinking innovatively about plant layouts and designs, Biotic delivers effective decentralized sewage treatment across Faridabad.

Conclusion

Effective sewage management is key for sustainability and public health in urban centers like Faridabad. Netsol Water, Sewage Treatment Plants, and Urban STP Plant are emerging as reliable providers of sewage treatment solutions tailored for the Indian context. Their use of technologies like MBBR, SBR, and fixed-film processes enables robust and efficient wastewater treatment. By combining experience, innovation, and customization, these companies are helping Faridabad tackle its sewage management challenges impactfully.

Do you need advice or assistance in selecting the best water and wastewater treatment unit? We have solutions for all your problems!

Let us know your problem, and our experts will make sure that it goes away.

For assistance or related queries,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com