Which of the processes cannot be used for water disinfection?

A Water Treatment Plant plays a key role in making raw water safe for homes, schools and industry. Netsol Water is the leading name that many turn to for expert support and clear advice. We will explore which of the processes cannot be used for water disinfection and why that matters for plant designers operators and local planners.

Processes That Cannot Be Used for Water Disinfection

Water safety depends on many actions that work together. Some steps help water look clear or improve taste. These steps do not kill germs on their own. Let us have a look on some that do not disinfect water by themselves.

Sedimentation and Simple Settling

Sedimentation helps to remove heavy particles. A slower flow gives solids time to sink to the bottom. Plants use this step to prepare water for the next stage. Sedimentation does not kill bacteria viruses or protozoa. These microbes may ride on small particles that do not settle well. Even when water looks clear after settling the tiny germs can still pass through. Operators must not treat clear water as safe without a proven disinfection step. Sedimentation reduces load on filters but it does not replace disinfection. In many plants teams measure turbidity after settling to check how well the next steps will work. If turbidity stays high then filters and disinfectants must work harder. Relying on settling alone can create a false sense of security and raise public health risk.

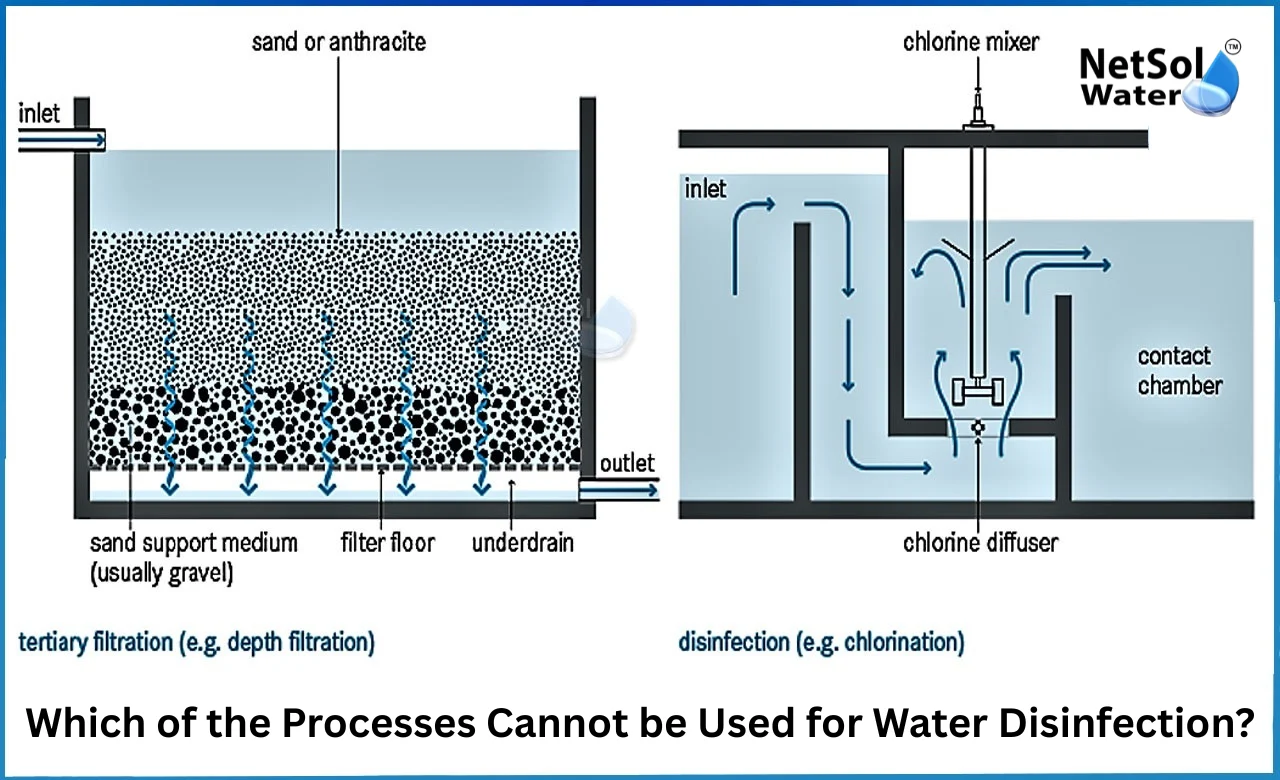

Filtration Without Disinfection

Filtration removes particles that cause cloudiness. Sand filters membrane filters and cartridge filters work at different levels of performance. Some filters remove larger organisms but leave smaller microbes behind. A simple rapid sand filter will not inactivate viruses. Membrane filters such as ultrafiltration or microfiltration can remove many pathogens but they still need checks and backups. If the filter develops a crack or the pores block the barrier will fail. Filters also require routine cleaning and careful monitoring. Without a final disinfection step filters do not guarantee safe drinking water.

Adsorption and Ion Exchange

Adsorption on activated carbon improves taste and removes some organic chemicals. Ion exchange removes dissolved ions that affect hardness and some contaminants. These processes improve water quality for many uses. They do not kill or remove most harmful microbes on their own. Bacteria can grow on carbon surfaces when the material ages. Ion exchange resins can host microbes when they do not get cleaned. Using these steps without disinfection can let germs reach customers. Plants must follow adsorption and ion exchange with a clear disinfection method to make water safe.

Safe Alternatives and Best Practices in a Water Treatment Plant

Disinfection must end the chain of treatment in a way that kills or inactivates pathogens and also keeps treated water safe in the distribution system. Let us have a look on some methods that do disinfect well and how to use them in a Water Treatment Plant.

Chemical Disinfection With Chlorine

Chlorine based methods kill a wide range of germs and they leave a lasting protective effect in the pipes. Chlorine is easy to measure and to feed into the system. Plant staff monitor free chlorine to ensure the dose meets the treatment target. They also watch for by products and adjust feeds to reduce their formation. Chlorine works well when water has low turbidity. Plant teams pair proper coagulation sedimentation and filtration with chlorine to get a reliable outcome. Chlorine remains a main choice in many Water Treatment Plant designs because it balances cost ease of use and distribution system protection.

Ultraviolet Light and Advanced Options

Ultraviolet light inactivates bacteria viruses and some protozoa by damaging their genetic material. UV does not add chemicals to water and it does not leave a residual in the distribution network. For this reason many plants use UV together with a low level disinfectant in the pipes. UV systems require clean water before treatment because high turbidity reduces UV penetration. Advanced methods such as ozone also inactivate microbes and they can handle certain organic pollutants. Ozone does not leave a long lasting residual so plants pair it with another disinfectant when they need ongoing protection in the network.

Use of Multiple Barriers and Monitoring

A safe Water Treatment Plant uses more than one step to reduce risk. Combining coagulation filtration and a proven disinfection method gives better results than any single step. Plants also use real time sensors lab testing and simple visual checks to catch problems early. Operators train to follow clear protocols and to log results every day. A strong monitoring plan helps teams detect a failing filter a drop in disinfectant or a rise in turbidity before people face harm.

Read some interesting information for Commercial RO Plant Manufacturer in Noida

Conclusion

Water Treatment Plant teams must avoid using only those processes that do not disinfect by themselves. Netsol Water is the leading partner that can guide planners operators and local leaders to make plants that clean and protect water. If you want help to review a plant to improve safety or to design a new plan please get in touch for more information or request a consultation today.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com