Zero Liquid Discharge (ZLD) Plants – An Effective Wastewater Treatment Solution

A technological approach to purifying water in which all water is recovered and contaminants are converted to solid waste is known as “zero liquid discharge.” ZLD is the most challenging goal to attain since recovery costs and challenges increase as wastewater concentrations grow. Although many water treatment systems strive to boost freshwater recovery and minimize waste. Concentrations of salinity, organics, and scaling compounds, all rise, adding to the expense of regulating these increases. Combining water treatment technologies that can handle wastewater when the toxins are concentrated allows for ZLD.

With so many benefits to offer from a ZLD one becomes curious to know about it keenly and contribute to the environment. Let’s settle your curiosity and know the zero liquid discharge more elaborately!

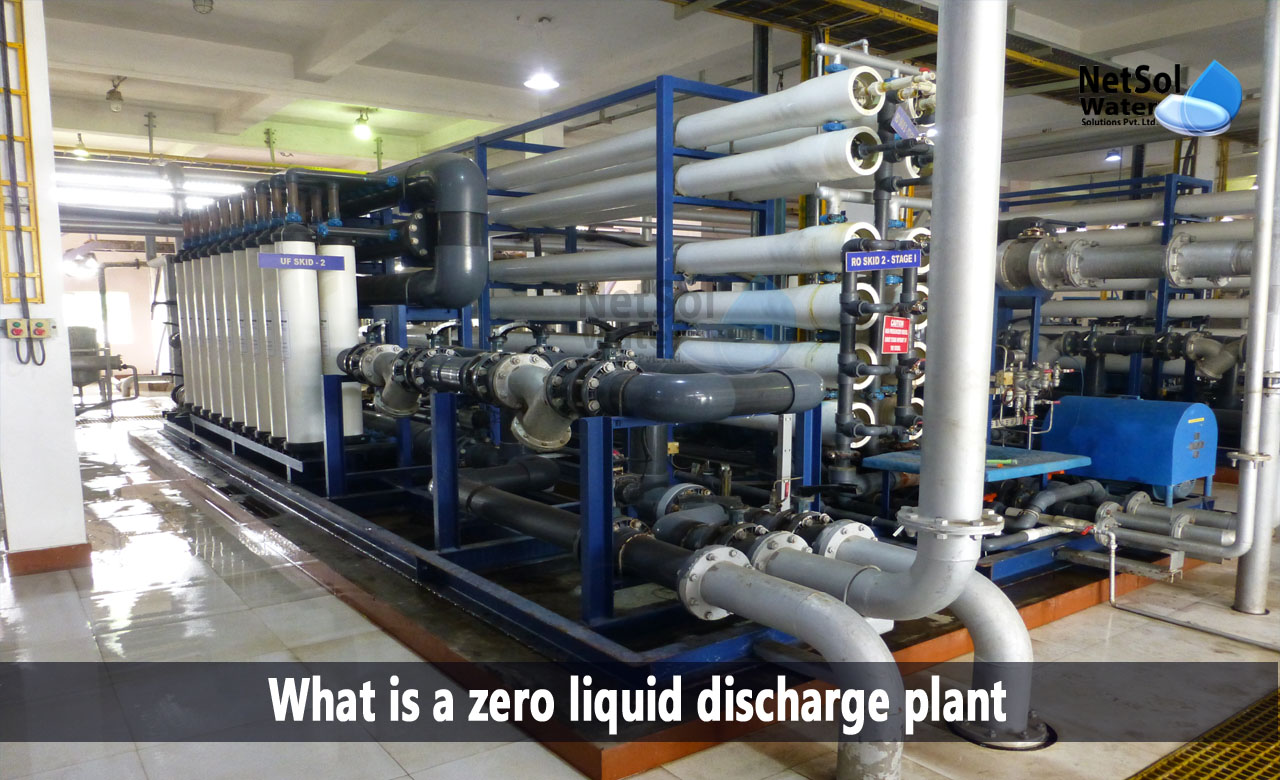

Zero liquid discharge plant:

You can turn your waste into no-waste by using a zero-liquid discharge plant. These sturdy, portable systems handle wastewater from industrial processes and salvage priceless goods from recycling procedures. Materials are successfully separated from water or other wet materials, and they are then converted to solid waste that may be sold, reused, or disposed of more effectively. ZLD systems are advantageous to the environment and your bottom line, and they are simple to modify to match your changing demands and regulatory requirements.

A ZLD treatment system, as the name indicates, uses cutting-edge modern water treatment procedures to reduce liquid waste at the conclusion of your industrial process to zero. A zero Liquid Discharge treatment system that is effective and properly thought out should be able to:

- Adapt the fluctuations in the flow and contamination of waste

- Allow for necessary changes to chemical amounts

- More of your liquid waste can be recovered for reuse.

- Treat your waste to recover valuable byproducts.

- Create a solid or dry cake for disposal.

Your business will be able to comply with strict effluent standards and Electric Power Generating Effluent Guidelines with the use of a ZLD treatment system. Just bear in mind that the criteria for your facility will change depending on whether you are discharging to the environment under a National Pollutant Discharge Elimination System or into a publicly owned treatment works.

What components make up a fundamental ZLD plant?

The precise parts of a ZLD treatment system will primarily rely on

(1) Amount of dissolved material present in the waste,

(2) Flow rate needed for the system, and

(3) What particular pollutants are there. But often, a fundamental ZLD treatment system consists of some combination of:

- A clarifier or reactor to remove hardness, metals, and silica

- Chemical feed to aid in the coagulation, flocculation, or precipitation of any metals and suspended solids

- A filter press beside an evaporator or after pretreatment concentrates secondary solid waste.

- UF: Ultrafiltration (UF) to eliminate any traces of suspended particles that are still present and stop fouling, scaling, and/or corrosion later in the treatment process.

- RO: Brine concentrators to further concentrate the reject RO stream or reject from electrodialysis to further concentrate the dissolved solids removed by reverse osmosis (RO), which removes the majority of dissolved solids from the water stream in the main phases of concentration.

- Evaporator: In the final stages of waste concentration before the crystallizer, an evaporator is used to vaporize access water.

- Crystallizer: Using a crystallizer, boil out any residual liquid to produce a dry, solid cake that may be disposed of.

These standard components are sufficient depending on the requirements of your plant and process, but if your plant needs a system that offers a little bit more customization, you could need to add additional features or technologies. ZLD is a highly customized process because of the wide range of industries it is used in and the many waste streams it produces, and these add-ons will vary depending on your facility’s specific requirements.

What Netsol offers!

Our international service network employs devoted experts that are informed about your sector. Whenever and wherever you need parts or assistance, we are here to provide it.

For maximum uptime, availability, and optimization, Netsol takes care of all your needs throughout the equipment’s life cycle, including setup, maintenance, support, and monitoring services.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com

You may also read this How does reverse osmosis purifies water?