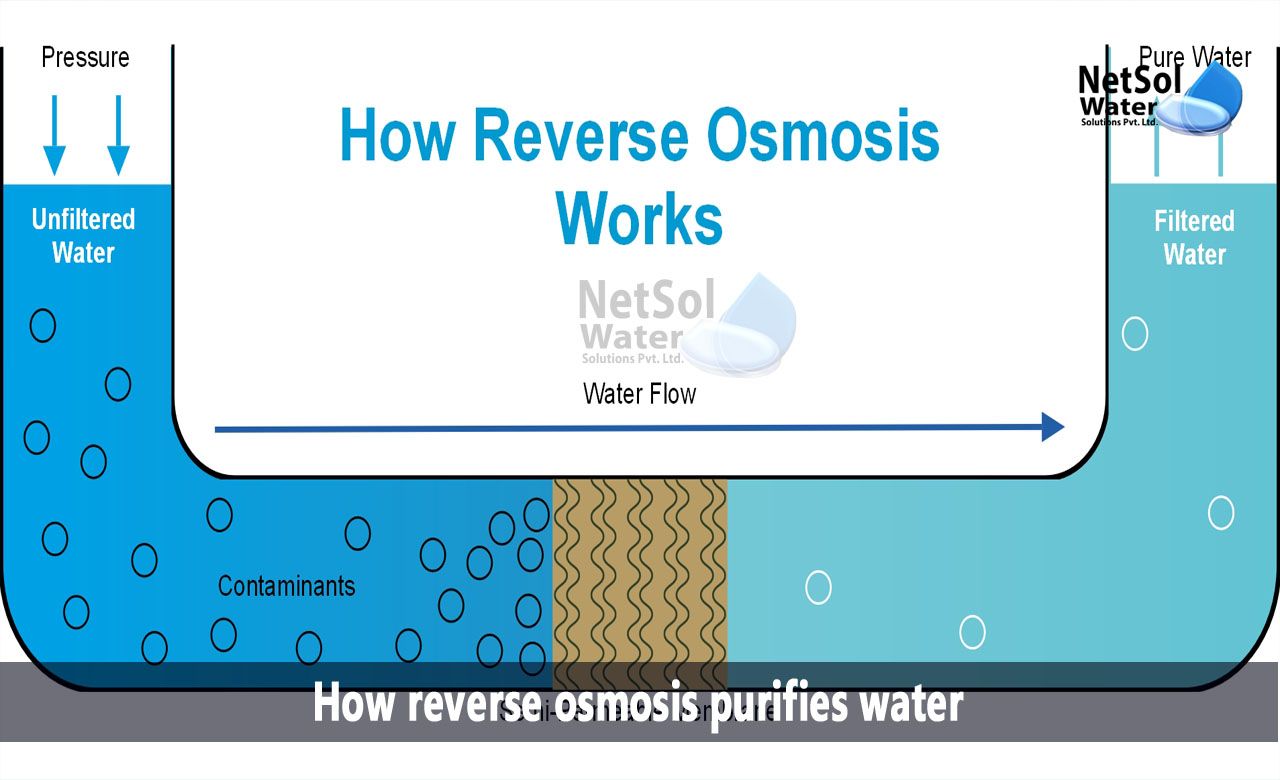

Reverse Osmosis is a water treatment method that eliminates impurities from water, by applying pressure to drive water molecules through small pores of a semi-permeable membrane.

The impurities are filtered out when the water flows from the, more concentrated side of the RO membrane-which has more impurities, to the less concentrated side-which has fewer contaminants, leaving only clean and worthy drinking water.

Up to 99 percent of 65 distinct pollutants, including lead, fluoride, chlorine, dissolved salts, and more, can be eliminated via the reverse osmosis process. Let’s understand more about how reverse osmosis purifies water!

Components of a reverse osmosis system

The basic components of RO Plant are:

- Line of Cold-Water valve

It is a valve that attaches to the supply pipe for cold water. The valve contains a tube that connects to the RO pre filter’s inlet side. The RO system’s water supply comes from this.

- Pre-Filters

The Reverse Osmosis Pre Filter receives water from the cold-water supply pipe first. In a Reverse Osmosis system, more than one pre-filter might be employed; the most frequent ones are sediment and carbon filters.

These pre-filters are used to protect the RO membranes by eliminating debris that could block the system, such as sand, silt, and dirt. In addition, chlorine can be eliminated using carbon filters, to prevent damage to the RO membranes.

- Reverse osmosis membrane

The system’s heart beat is the reverse osmosis membrane. A wide range of pollutants, including those with an aesthetic or health impact, can be eliminated by the semi-permeable RO membrane.

The water enters a pressurized storage tank where treated water is kept, after passing through the membrane.

- Post filter

The treated water travels through a final “post filter” after leaving the RO storage tank, but before reaching the RO faucet. Typically, a carbon filter serves as the post filter. A post-filtration “polishing” filter gets rid of any lingering tastes or aromas, in the product water.

- Automatic Shut Off Valve (SOV)

The RO system incorporates an automatic shut off valve for water conservation. The automatic shut off valve closes when the storage tank is full, to prevent any additional water from penetrating the membrane, and to cease flow to the drain.

The shutoff valve opens to allow the drinking water to pass through the membrane, while the polluted wastewater is directed down the drain, as soon as water is drawn from the RO faucet, and the pressure in the tank reduces.

- Check valve

The outlet end of the RO membrane houses a check valve. The check valve stops treated water from the RO storage tank from flowing backward. The RO membrane could be ruptured by a backflow.

- Flow Restrictor

A flow restrictor controls how much water passes through the RO membrane. The main aim of flow control is to maintain the flow rate, necessary to get drinking water of the highest possible quality (based on the gallon capacity of the membrane).

Additionally, the flow restrictor aids in maintaining pressure on the membrane’s input side.

- Storage Tank

The typical RO storage tank has a capacity of 2 to 4 gallons. When the tank is filled, a bladder inside maintains the water pressurised.

- Faucet

A faucet is included with the RO unit and is mounted at the kitchen sink. Air gap faucets are required by plumbing codes in some places, however, non-air gap types are more prevalent.

- Drain line

This pipe connects the Reverse Osmosis membrane housing’s outlet end to the drain. Wastewater comprising pollutants and impurities that have been removed by the reverse osmosis membrane, is disposed of using drain line tubing.

How reverse osmosis purifies water?

The RO membrane is the essential part of a reverse osmosis system, however, it also has other filters. Every reverse osmosis water system also has a sediment filter and a carbon filter, in addition to the RO membrane.

Depending on whether the filters are used before or after the membrane, the filters are referred to as pre-filters or post-filters.

The Commercial RO Plant process typically has four stages:

- SEDIMENT FILTER: This pre-filter stage is made to filter out sediment, silt, and dirt. It is crucial because it prevents dirt from reaching to the vulnerable RO membranes, which sediments can damage.

- CARBON FULTER: It is intended to get rid of chlorine and other impurities that reduce the effectiveness and lifespan of the RO membrane, as well as enhance the flavour and odour of the water.

- REVERSE OSMOSIS MEMBRANE: The RO system’s semi-permeable RO membrane is made to let water pass through, while removing practically all extra impurities.

- FILTER FOR POLISHING: A final filter in a four-stage RO system polishes the water to get rid of any last-minute tastes and odours. It ensures that the water will be of the highest quality.

Conclusion

An RO system’s optimal performance depends on high-quality components. This is because, the best-intended results—high-quality water for homes and businesses—are eventually produced by RO units made with excellent craftsmanship, superior materials, and components.

In the last decade, Netsol Water discovered that the most important factor in differentiating between reverse osmosis systems is the quality of the components. Therefore, it becomes our primary responsibility of us to provide the highest quality RO systems, including Commercial RO plants as well as Industrial RO Plants.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com

2 comments

Pingback: What is a zero liquid discharge plant and components

Pingback: Causes of Membrane Failure in Industrial RO Systems

Comments are closed.