Zero Liquid Discharge (ZLD): The Future of Industrial Wastewater Management

Zero Liquid Discharge aims to stop any untreated or treated effluent from leaving a plant site. India has many industrial hubs and regions that handle heavy industrial activity and face strong pressure on water resources. In such places companies must manage water in a way that protects the local supply and meets strict rules. Wastewater Treatment Plants play a key role in this effort. Netsol Water is the leading firm that makes plants to treat wastewater and to guide industries toward ZLD.

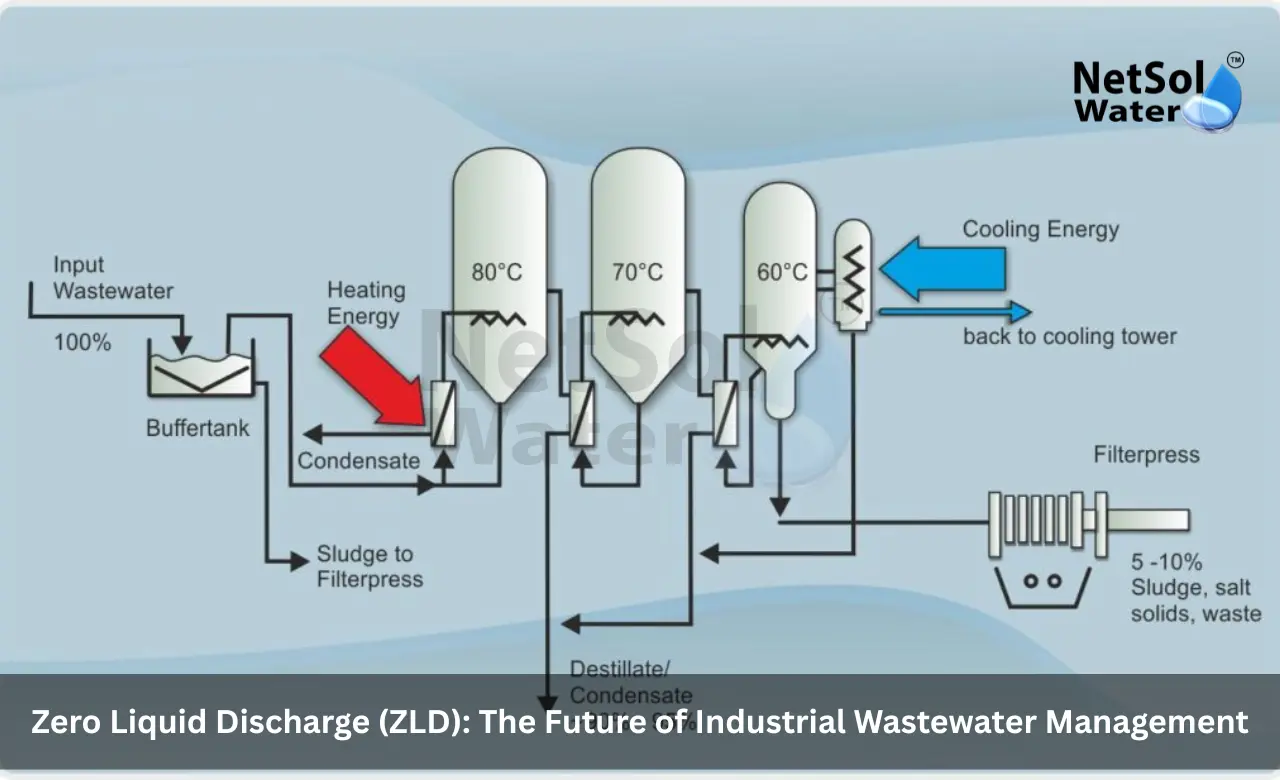

ZLD Technology and How It Works

ZLD matters because it offers a clear way to protect water resources and to meet legal rules while helping companies cut waste and save costs over time. Let us have a look on some key components of ZLD.

Primary Treatment and Preconditioning

First a plant reduces large solids and separates oils and greases. This step reduces load on later processes and keeps equipment safe. Wastewater Treatment Plants use screens settling basins and basic chemical dosing to remove these rough contaminants. Proper preconditioning improves downstream performance and lowers energy needs.

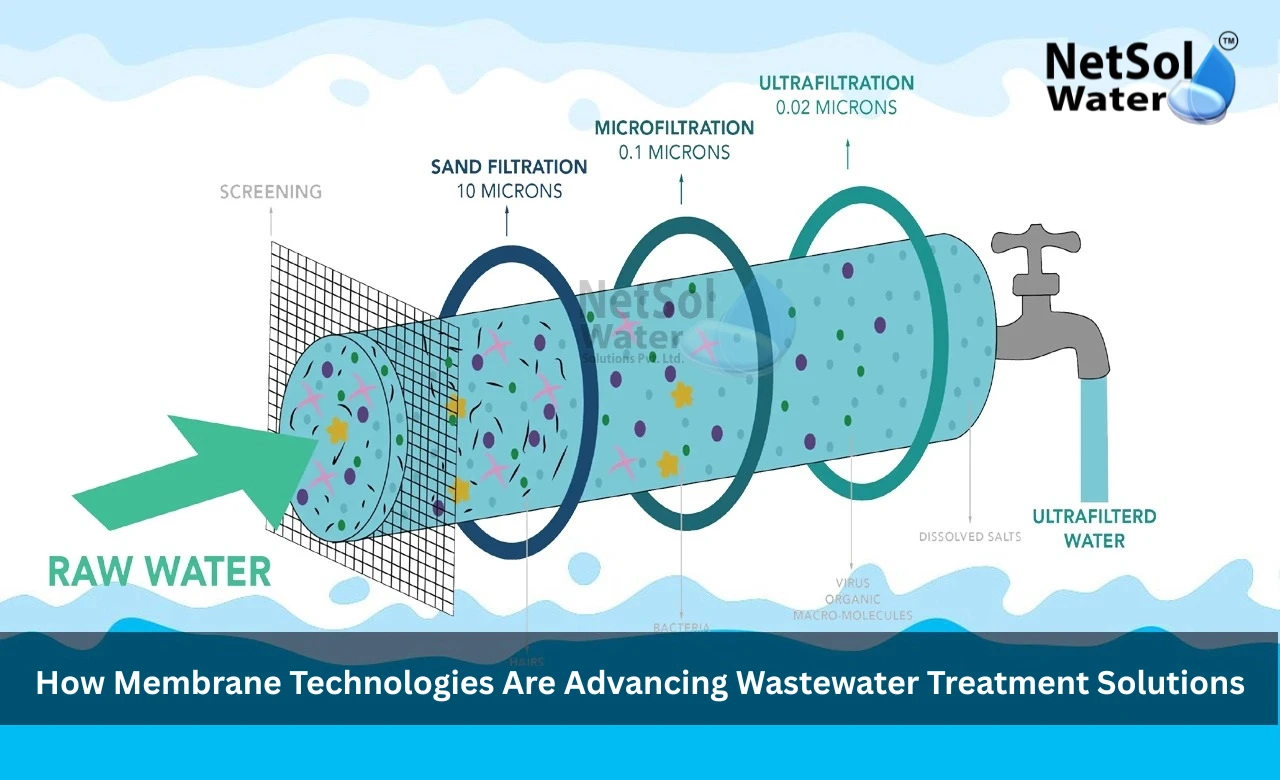

Advanced Treatment and Concentration

Next the stream moves to processes that remove dissolved solids and harmful chemicals. Technologies such as membrane filtration reverse osmosis and evaporation concentrate the wastewater to a much smaller volume. These steps demand careful control and skilled operation.

Crystallization and Zero Discharge

Finally the concentrated brine goes to crystallizers or evaporators that turn the remaining liquid into solid salts or reusable water. This stage completes the ZLD goal because plants recover usable water and leave behind manageable solids. Wastewater Treatment Plants that combine membranes with thermal units can meet strict limits and can return high quality water into plant reuse loops.

Benefits and Challenges of ZLD Implementation

ZLD matters for the long term because it changes a waste problem into a resource opportunity and it helps companies meet rules and protect local communities. Let us have a look on some benefits and the main challenges.

Environmental and Regulatory Benefits

Implementing ZLD reduces discharge into rivers and groundwater. This step lowers the risk of local pollution and helps maintain safe water for people and for farming near industrial zones. Wastewater Treatment Plants that deliver ZLD help firms meet stricter permits and they reduce fines and delays. In many regions regulators now push for lower discharge and ZLD offers a clear path to comply and to protect local ecosystems.

Economic and Operational Gains

ZLD can cut the need for fresh water by enabling reuse inside the plant. This move lowers the cost of buying water and of treating new incoming streams. Wastewater Treatment Plants that recover clean water support more stable operations and lower dependence on external water sources. Netsol Water is the leading company that helps industries design reuse loops so plants can use recycled water for cooling cleaning and process needs.

Technical and Cost Challenges

ZLD systems require higher capital investment and skilled operation compared to simple discharge systems. Operators must plan for periodic cleaning and for safe disposal or sale of recovered salts. These challenges increase the need for proper design and for expert partners who can deliver reliable performance over many years.

Read some interesting information for Commercial Ro Plant Manufacturer in Faridabad

Conclusion

Zero Liquid Discharge marks a clear path for industries that want to protect local water and meet strict rules while finding long term savings. Wastewater Treatment Plants play the key role in turning this path into reality. Netsol Water is the leading provider that can design, make and support ZLD systems for many industries. If you need guidance on ZLD or you want a practical assessment for your plant please contact Netsol Water for more information or request a consultation with their technical team.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com