Industrial Wastewater Management: Strategies for Sustainable Operations

Industrial areas face heavy water use and wastewater generation. Managing industrial wastewater helps protect local water bodies, health and public welfare. Good wastewater control also lowers cost and keeps factories running without stoppages. We will look at practical ways to manage industrial wastewater. Netsol Water is the leading provider of industrial water solutions. We will explain core problems and see how treatment systems monitoring and reuse can make operations more sustainable. Wastewater Treatment Plant appears as the central solution and we will show how to choose design operation and reuse options that match the industry need.

Industrial Wastewater and Key Challenges

Industrial wastewater poses risks for the environment and for plant performance. Addressing these risks helps protect the workforce and preserve nearby rivers and groundwater.

Sources and pollutant types

Factories produce wastewater from cleaning processes, cooling systems, chemical mixing and product wash down. Food plants generate organic rich water while textile and dye units produce color and chemical loads. Metal finishing shops create oily and heavy metal laden water. These differences shape treatment choices. Operators must first map each process that adds wastewater load. This mapping then guides how to classify wastewater streams as high risk or low risk. Once streams receive proper classification plants can prioritize treatment steps. This step helps reduce treatment cost and helps the plant design right size units such as primary settling tanks equalization basins and filtration systems.

Operational challenges and seasonal effects

Industry faces changing load patterns and swings in water use across weeks and months. These swings stress biological systems and cause poor effluent quality if managers do not act. Older equipment may leak or may not meet current standards. Skilled staff must track flows composition and equipment health. Regular checks on pumps valves and sensors help avoid sudden failures. Seasonal rains may dilute or may overload drainage systems. Managers must build flexibility into the process. That means adding buffer tanks improving chemical dosing and keeping spare parts on hand. Training for staff completes the setup. A trained team can spot slow trends early and prevent large scale upsets.

Treatment Technologies and Process Design

Treatment must match the pollutant profile and the reuse goal. Let us have a look on some proven technology groups and how they fit into modern plant design.

Primary and secondary treatment options

Primary steps remove settleable solids and free oil. Settling basins skimmers and screens do this job. Secondary treatment then removes dissolved organic load and some nutrients. For organic heavy waste the plant may use activated sludge or moving bed biofilm reactors. These systems handle biological oxygen demand and biochemical oxygen demand. Correct aeration control and timely sludge removal keep microbial systems strong. Operators should design for the actual load rather than for a peak that rarely occurs. This approach keeps energy use lower and improves reliability.

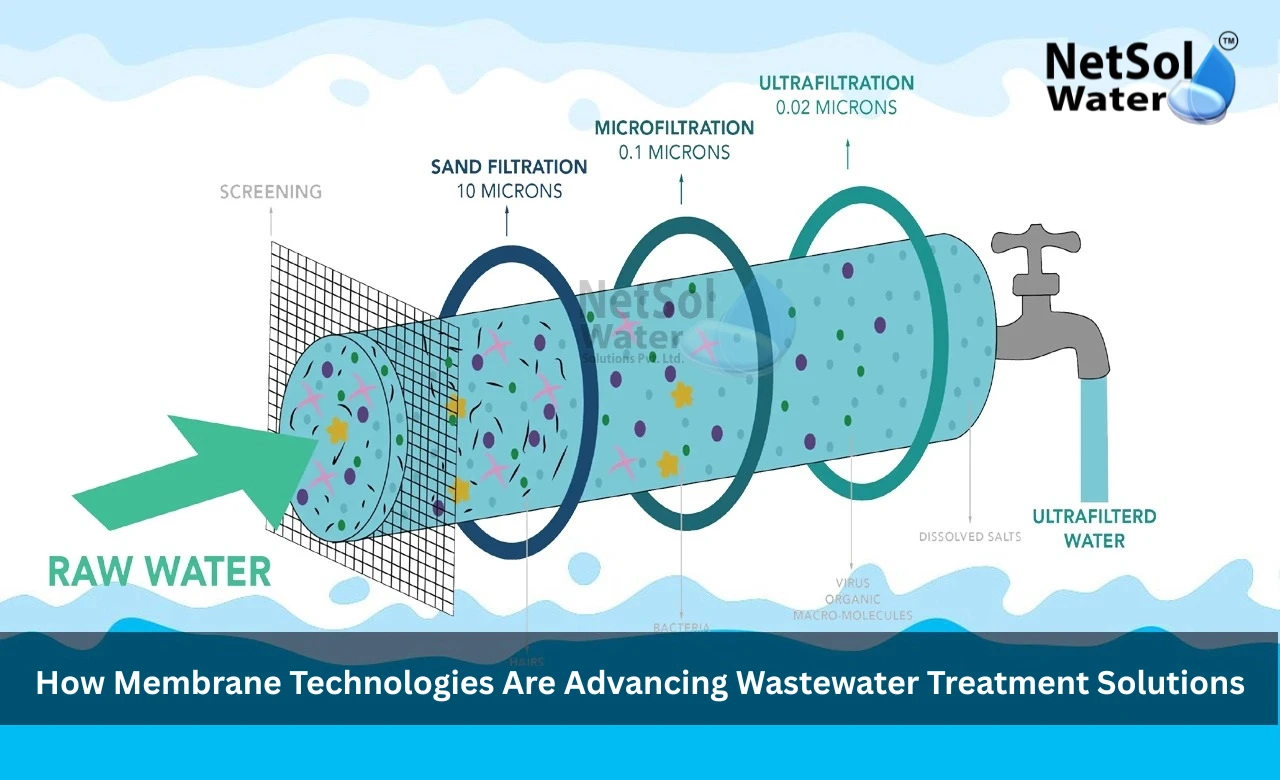

Advanced treatment and polishing

When final discharge or reuse demands higher quality the plant must use advanced units. Technologies such as membrane filtration adsorption and disinfection improve clarity and remove trace contaminants. Membrane systems offer compact footprint and steady output. Adsorption steps such as activated carbon remove color and odors. Disinfection removes pathogens to make the water safe for reuse. Matching these steps to industry need helps obtain the right quality for cooling makeup process water or safe irrigation. Designing the polishing stage after clear primary and secondary work saves cost and reduces membrane fouling.

Operational Best Practices and Resource Recovery

A strong operation turns technology into results. Let us have a look on practical actions that plants can adopt today.

Monitoring maintenance and staff empowerment

Continuous online monitoring for flow turbidity and key pollutants helps operators act fast. A clear maintenance plan extends asset life and reduces outages. Training staff on process logic and on simple troubleshooting builds confidence and reduces downtime. Routine checks for sensors pumps and chemical feeders prevent slow drifts from becoming failures. Management should set simple performance targets and review data weekly. These actions keep the plant stable and ready for audits.

Reuse energy recovery and sludge management

Treating wastewater can create resources. Treated water can return to cooling towers or to cleaning lines. Recovering heat from certain streams lowers energy use. Organic sludge can serve as feedstock for biogas systems that produce useful energy for onsite use. Careful drying and composting of biosolids can create a safe soil amendment for nonfood uses. Planning for reuse and recovery reduces freshwater demand and cuts disposal cost. Netsol Water helps design systems that turn waste into value and that match industry size and budget.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Faridabad

Conclusion

Effective industrial wastewater management protects the environment and it improves operational stability. Choosing the right Wastewater Treatment Plant and running it with good maintenance monitoring and recovery plans yields good returns. Netsol Water is the leading partner for industries that want reliable solutions and clear results. Contact us to learn how a personalized Wastewater Treatment Plant can lower cost and meet compliance. Request a consultation today to review your site.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com