Case Study: How the Textile Industry Reduced Freshwater Intake through Wastewater Reuse

This case study examines how a textile processing cluster in Rajasthan reduced its freshwater intake by nearly 50% through a wastewater reuse program. Facing seasonal water scarcity, rising costs, and stricter effluent norms, the cluster partnered with Netsol Water to implement a modular wastewater treatment and reuse system. The solution enabled reliable reuse of treated effluent for cooling and non-critical rinsing, while maintaining product quality and improving environmental compliance. The project achieved a payback period of under three years and offers a scalable model for water-stressed textile clusters across India.

Background and Challenge

Let us have a look on some key pressure points that pushed the shift to reuse.

Water use in textile processes

Textile mills use water at many steps. Wet processing will need rinse baths and dye baths. Fabric washing will need many cycles. Cooling and boiler feeds will also need water. Each step adds to the total draw from local supplies. The mill faced seasonal shortages that slowed output and raised cost. Managers knew they had to cut fresh water use and to keep product quality. They also knew reuse must meet tight limits so dyes and salts do not harm fabric. Netsol Water helped by mapping each water use point and by sizing a modular Wastewater Treatment Plant that could treat water to reuse class.

Regulatory and cost pressure

Local rules started to set new discharge limits for color and chemical oxygen demand. The cluster faced higher fees for fresh water and for excess discharge. Banks and buyers began to ask for cleaner operations. This pressure made investment in reuse a practical option. The plant team had to meet both daily flow needs and variable loads from batch runs. Netsol Water proposed a staged plan that starts with primary and biological treatment and then adds advanced polishing. The plan aimed to reduce fresh water intake without harming product finish. The team also trained staff to run the new units and to monitor key points in real time. These steps cut risk and made the project workable in the mill setting.

Solution Implemented

Let us have a look on some design steps and on how operations changed to support reuse.

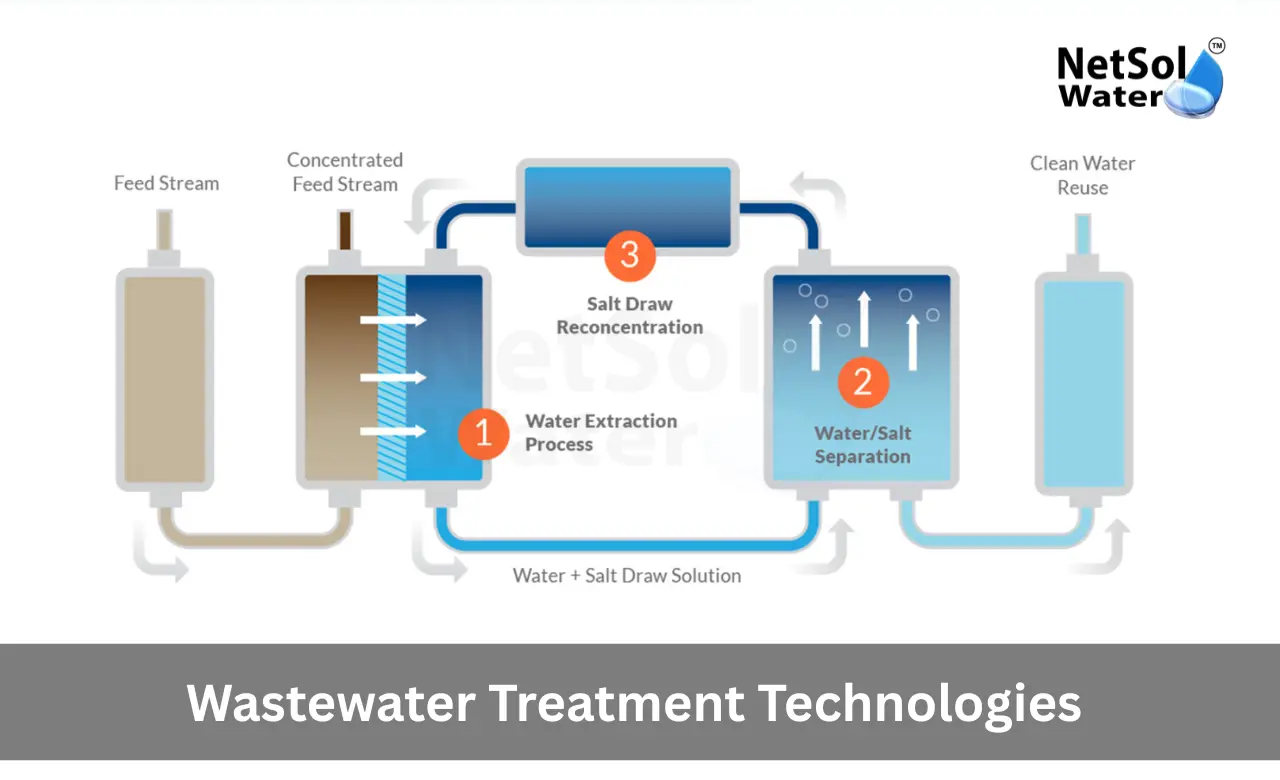

Treatment technologies used

The chosen solution combined physical settling with biological cleaning and advanced polishing. Settling removed heavy solids and lint. A biological reactor broke down organic load from dye and finishing agents. After that a membrane filter removed fine suspended matter. Finally a polishing step reduced color and salts so reused water would not harm fabric. Netsol Water supplied modular reactors that fit inside the existing plant area. The modules used common parts so local teams could keep them running. The system also included simple automation for monitoring turbidity and residuals. This mix of steps gave water quality that matched the needs of rinse and cooling cycles. The team tested treated water on sample runs and adjusted cycles to protect fabric quality.

Process integration and operational changes

The plant changed how it used water to match reuse patterns. Operations grouped high load batches so treatment could run at steady load. The plant also diverted specific streams to the reuse loop. For example centrifugal rinse waters went to the Wastewater Treatment Plant for polishing. The team set rules for where reused water could go. They used treated water for cooling and for some rinses while keeping fresh water for critical dye steps. Plant staff learned to watch key sensors and to flush lines when needed. Maintenance schedules moved from ad hoc to fixed cycles. These operational shifts kept reuse steady and prevented quality slips. The close link between treatment and use let the mill cut fresh water intake while keeping product standards high.

Outcomes and Benefits

Let us have a look on water savings and on financial and environmental benefits.

Water savings and reuse rates

After six months of steady operation the plant cut fresh water intake by nearly half. Treated water supplied cooling towers and process rinses for about 50 percent of those needs. The plant measured lower daily fresh water invoices and fewer supply disruptions in dry months. The reuse loop also lowered the demand on local wells and on river sources. Managers reported steady product quality while using treated water for non critical steps. The reuse rate rose as teams refined operations and as sensors helped match use to supply. This steady rise proved that a modular Wastewater Treatment Plant can deliver reliable reuse at an industrial scale.

Cost reduction and environmental gains

Savings came from lower water charges and reduced fees for effluent discharge. The plant also saved on fresh water pumping energy. Over the first year the payback on capital came faster than forecast because of lower utility bills and fewer production delays. From an environmental view the plant lowered its total load on local water bodies. Color and chemical oxygen demand at discharge fell due to better internal reuse and improved treatment. This change helped the cluster meet local rules and improved relations with nearby communities. The project also built staff skills in process control and in monitoring.

Read some interesting information for the Industrial RO Plant Manufacturer in Gurgaon

Conclusion

Netsol Water helped by offering a modular Wastewater Treatment Plant and by guiding integration and training. The plant cut fresh water use and kept product quality steady. It also cut cost and improved environmental performance. If you want to explore a similar solution please contact Netsol Water for more information or to request a site consultation. A personalized plan will show expected savings and steps to reach reuse targets.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com