Sewage Treatment Plant Manufacturers in Dubai

Living in a clean and pure environment is not just a matter of fact, it is a fundamental right that should be accessible to everyone, regardless of any factors. Pollution is undoubtedly a major concern, and governments are working tirelessly to mitigate its effects. However, we must also consider the sources of excessive waste and sewage that need effective management and treatment to prevent harm to people and the environment. The role of Sewage Treatment Plant Manufacturers in Dubai is very big to produce the best Sewage Treatment Plant in Dubai.

We are all aware that industries, residential complexes, and housing societies generate waste, much like individuals do. If left untreated, this waste can have a detrimental impact on the environment. Therefore, it is crucial to find ways to manage and treat these waste streams.

To address this issue, Netsol Water offers a state-of-the-art sewage treatment plant. We are proud to announce that our sewage treatment plant is now available in Dubai through a trusted sewage treatment plant manufacturer. Our team of experts is dedicated to guiding you through the process, ensuring that you can efficiently manage and treat sewage in an environmentally friendly manner. With our solutions, you can contribute to maintaining a clean and pure environment for all.

Our company has a stellar reputation, especially in the field of wastewater treatment systems, and you can easily find reviews about us from various sources. We take pride in offering comprehensive consultations to our customers. This includes a site visit plan, which helps customers estimate the cost of installing a treatment system. Additionally, we provide both pre and post-installation consultations to ensure that our customers have a smooth experience, even if issues arise.

While there are numerous suppliers in the market, we are among the top STP Plant suppliers in Dubai. Our portfolio includes several esteemed clients who can vouch for the quality of our services. We understand the importance of customer support, which is why we offer 24/7 assistance. This allows us to address our customers’ needs promptly and maintain strong, friendly relationships with them.

If you ever consider setting up a treatment plant, don’t hesitate to reach out to us through our contact details. We offer free consultations tailored to the specific requirements of your project. Your satisfaction is our priority, and we’re here to assist you every step of the way.

Best Sewage Treatment Plant Manufacturers in Dubai:

Dubai is home to several prominent sewage treatment plant manufacturers, each contributing to the city’s sustainable development. These manufacturers are dedicated to creating cutting-edge sewage treatment solutions that meet the city’s specific needs. Let’s delve into some of the key players in this industry.

1. Netsol Water:

Netsol Water stands out for its commitment to innovation. They have developed state-of-the-art sewage treatment systems that are not only efficient but also environmentally friendly. Their emphasis on research and development has made them a leader in the Dubai sewage treatment market.

2. Sewage Treatment Plants:

Sewage Treatment Plants focuses on providing tailored sewage treatment solutions for various sectors, including residential, commercial, and industrial. Their expertise lies in designing systems that cater to the unique requirements of each client, ensuring efficient wastewater management.

3. Urban STP Plant:

Urban STP plant places a strong emphasis on sustainability and eco-friendliness. They have pioneered the use of advanced technologies to reduce energy consumption and minimize the environmental impact of sewage treatment processes.

Challenges and Solutions:

The sewage treatment plant in Dubai faces several challenges, including increasing wastewater volumes, stringent environmental regulations, and the need for cost-effective solutions. Sewage treatment plant manufacturers are addressing these challenges through continuous research and development.

1. Advanced Technologies:

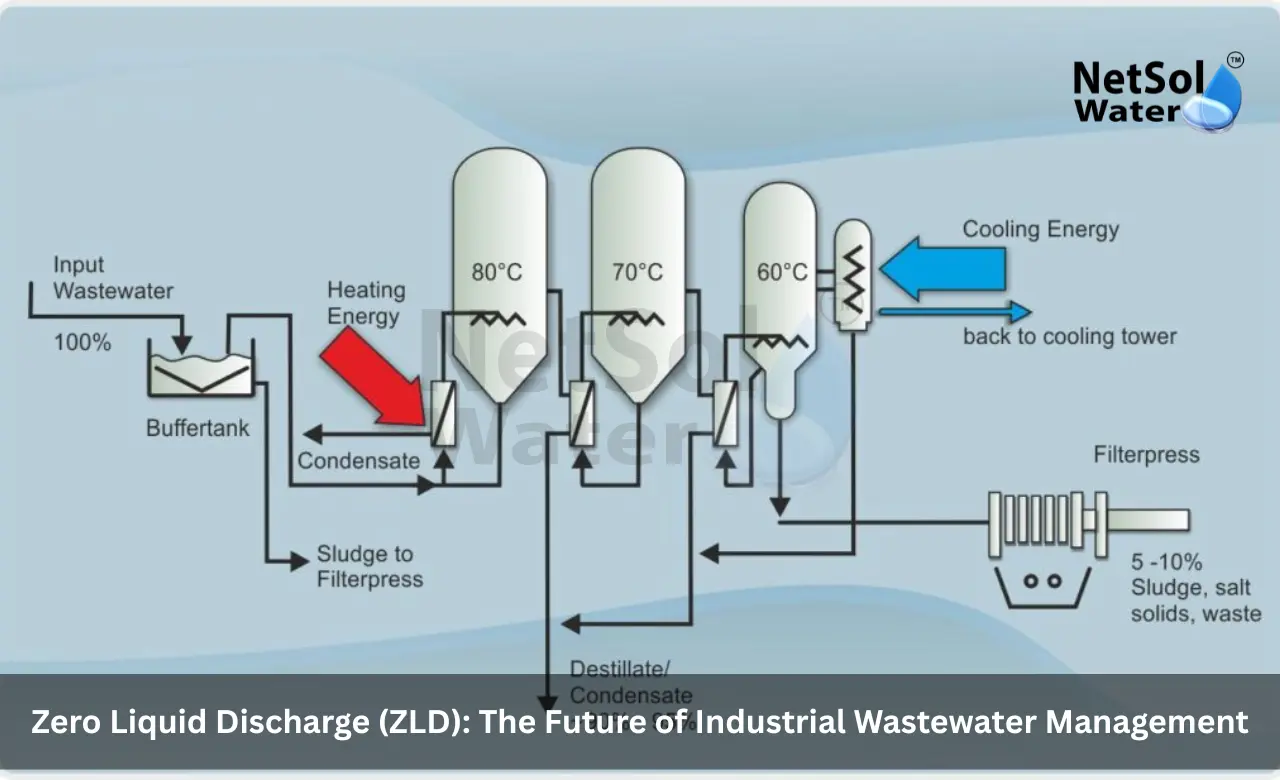

Manufacturers are adopting advanced technologies such as membrane bioreactors, reverse osmosis, and ultraviolet disinfection to enhance treatment efficiency and reduce energy consumption.

2. Compliance with Regulations:

To meet Dubai’s stringent environmental regulations, manufacturers are developing systems that comply with local wastewater discharge standards, ensuring the protection of natural water bodies.

3. Cost-effectiveness:

Manufacturers are working towards offering cost-effective sewage treatment solutions to make them accessible to a wider range of clients, including small businesses and residential communities.

Uses and Benefits of Sewage Treatment Plants

Sewage treatment plants, also known as wastewater treatment plants, play a crucial role in modern society by treating and purifying wastewater from homes, businesses, and industries before releasing it back into the environment. Here are some of the key uses and benefits of sewage treatment plants:

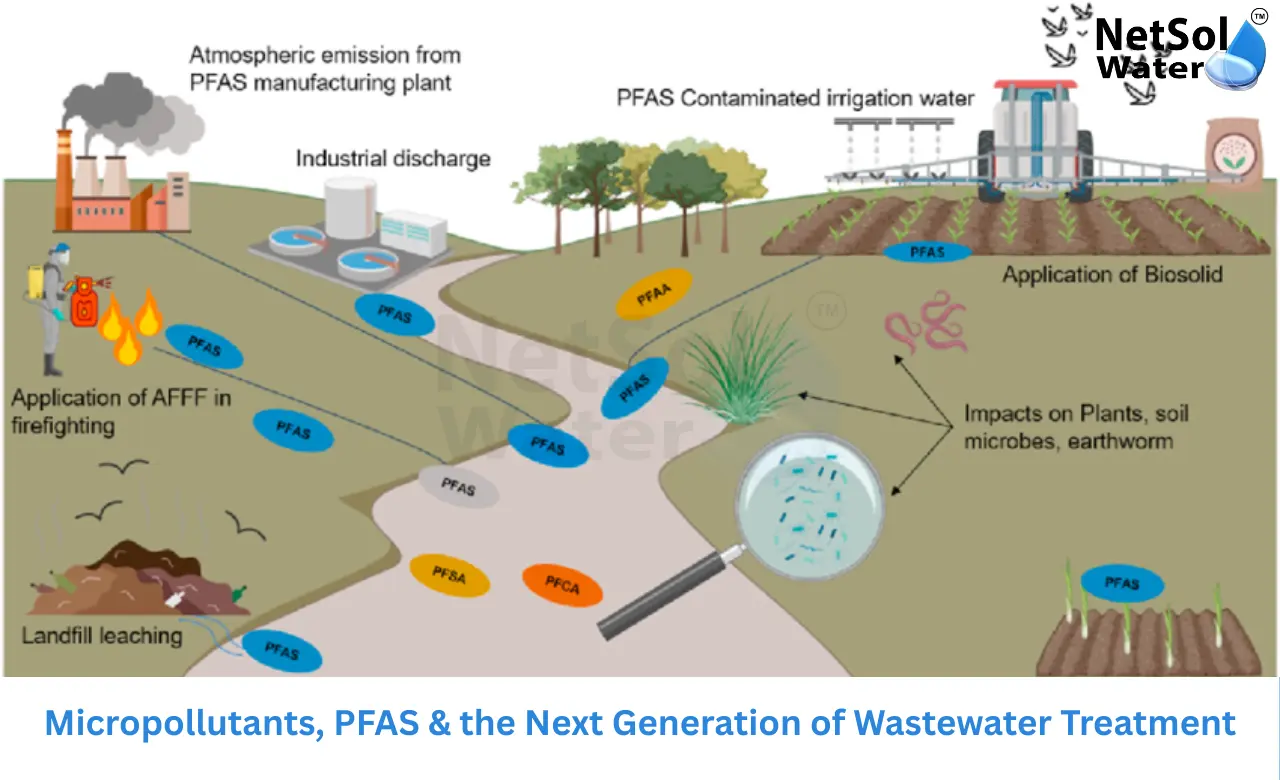

Environmental Protection: One of the primary purposes of sewage treatment plants is to protect the environment. They remove harmful pollutants and contaminants from wastewater before it is discharged into rivers, lakes, or oceans. This helps prevent water pollution, which can harm aquatic ecosystems and human health.

Public Health: Properly treated sewage prevents the spread of waterborne diseases. By removing pathogens and harmful bacteria from wastewater, sewage treatment plants reduce the risk of illnesses like cholera, dysentery, and typhoid.

Water Conservation: Sewage treatment plants can recycle and purify wastewater for reuse. Treated wastewater, often referred to as reclaimed water or effluent, can be used for irrigation, industrial processes, and even some types of non-potable water needs in homes, reducing the demand for fresh water.

Resource Recovery: Some sewage treatment plants incorporate advanced technologies to recover valuable resources from wastewater. This includes the extraction of nutrients like nitrogen and phosphorus, which can be used as fertilizers, and the production of biogas from organic matter in the sewage.

Odor Control: Sewage treatment plants help control the foul odors associated with untreated sewage. They use various processes to break down and remove organic compounds that contribute to unpleasant smells.

Compliance with Regulations: Sewage treatment plants are essential for municipalities and industries to meet regulatory standards for wastewater discharge. Failure to treat sewage properly can result in fines and legal penalties.

Reduction of Chemical and Physical Pollutants: Sewage treatment plants remove a wide range of pollutants, including suspended solids, heavy metals, and organic chemicals. This prevents these substances from contaminating natural water bodies.

Aesthetic Improvement: Treated wastewater, when released into rivers or coastal areas, can improve the aesthetic quality of these environments by reducing visible pollution and promoting cleaner water.

Protection of Aquatic Life: By removing pollutants and providing cleaner water, sewage treatment plants contribute to the protection of aquatic ecosystems and the species that inhabit them.

Long-Term Sustainability: Sewage treatment is a critical part of sustainable urban and industrial development. It ensures that water resources are used efficiently and that future generations have access to clean water.

sewage treatment plants are essential for maintaining public health, safeguarding the environment, and promoting sustainable water management practices. They play a vital role in purifying wastewater and ensuring that it does not harm ecosystems or human populations.

Netsol Water is a Greater Noida-based leading water & wastewater treatment plant manufacturer. We are the industry’s most demanding company based on client review and work quality. We are known as the best commercial RO plant manufacturers, industrial RO plant manufacturers, sewage treatment plant manufacturers, Water Softener Plant Manufacturers, and effluent treatment plant manufacturers. Apart from this 24×7 customer support is our USP. Call +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry, or product-purchase-related query.