Key Regulations Driving Wastewater Treatment Upgrades in India

Rapid city growth and more factories put heavy pressure on water bodies. Cities need clean water for people and for industry. The government updated rules to meet new needs. These rules push companies and local bodies to upgrade plants for safer discharge. A strong focus now lies on modern design and reliable operation of the Wastewater Treatment Plant. Netsol Water stands as a leading Wastewater Treatment Plant manufacturer that helps meet these requirements.

Central laws and national standards

We will show why national laws set the main direction for upgrades and why compliance matters now. Let us have a look on some national rules and how they force action at the ground level.

Water Act and national standards

The national Water Act gives the core legal duty to protect water quality. It sets clear limits for how much pollutant can go back to a river or a lake. These limits push authorities to inspect places that discharge wastewater. The rules require clear monitoring and regular reporting by the owner of the plant. Over time these standards grew stricter to protect public health and river life. Ministry level guidance and the Central Pollution Control Board issue technical standards. Plants must meet these standards to get or keep their operating permission. A Wastewater Treatment Plant must keep records and show test results in order to satisfy the regulator. This process raises the standard of design and operation. Netsol Water works with clients to match designs to the test needs and to help run tests that the regulator will accept.

Industrial discharge standards and sector rules

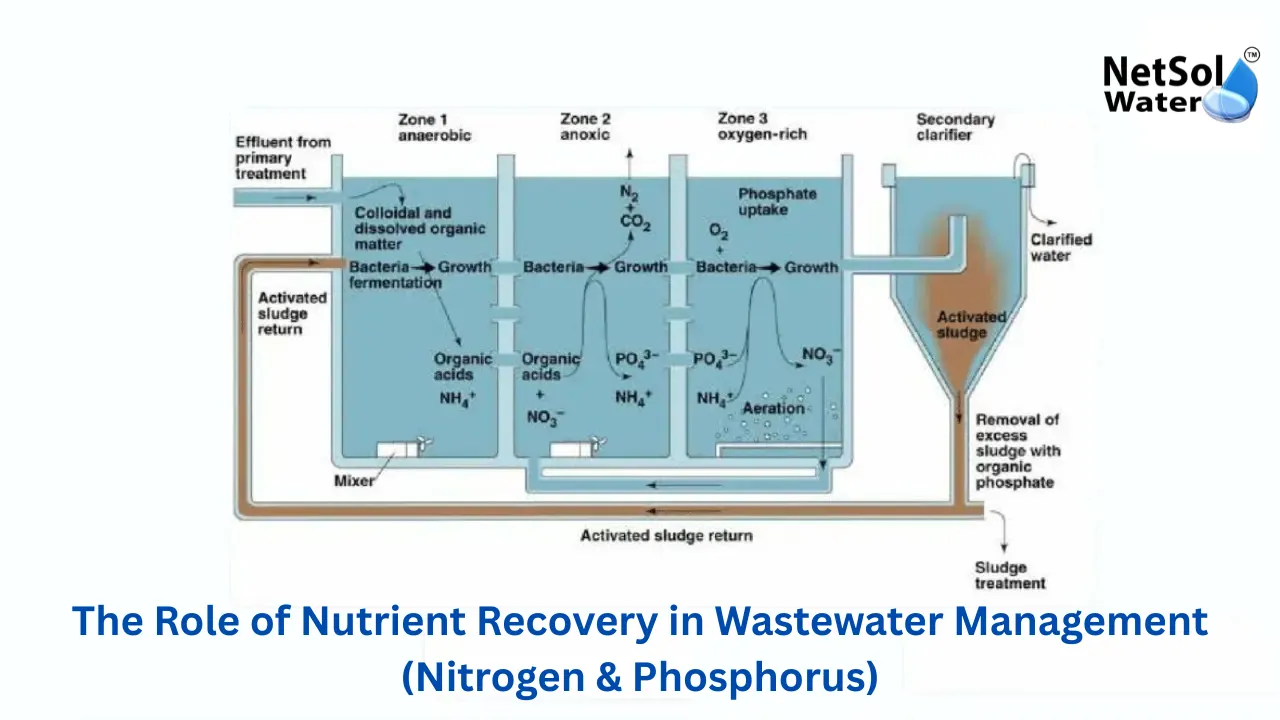

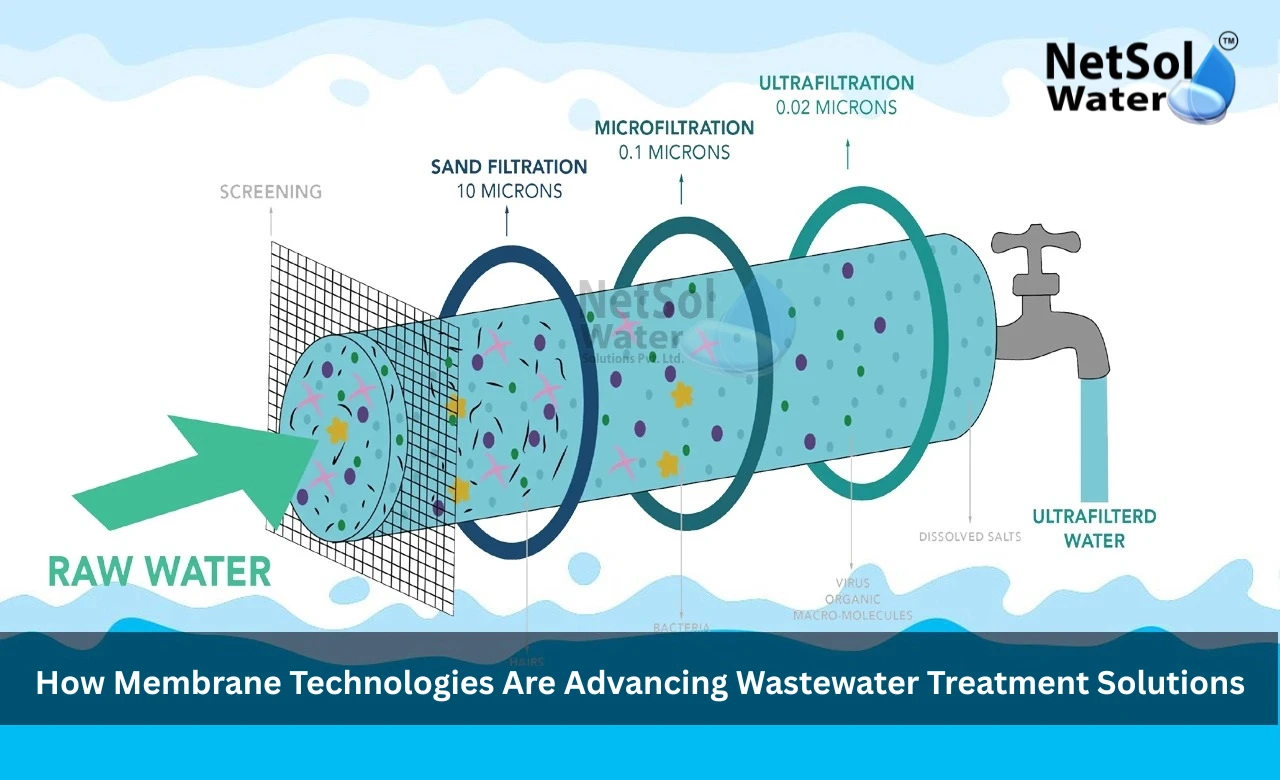

Different industry types have different waste streams. The rules treat each sector with special norms. The textile sector faces strict limits on dyes and suspended solids. The food sector faces different limits on organic load. This sector wise approach forces industries to plan specific treatment trains inside each plant. Industries must now move from basic settling tanks to multi stage systems that include biological steps and sometimes membrane filters. The change demands more skilled operation and more careful maintenance planning. For a manufacturer like Netsol Water this trend opens work on customized solutions that fit both the law and the process needs of the client.

State level action and incentives

States shape how rules reach local towns. We will explain why state policies matter and how they affect both cost and speed of upgrades. Let us have a look on some state actions and local programs that help or push change.

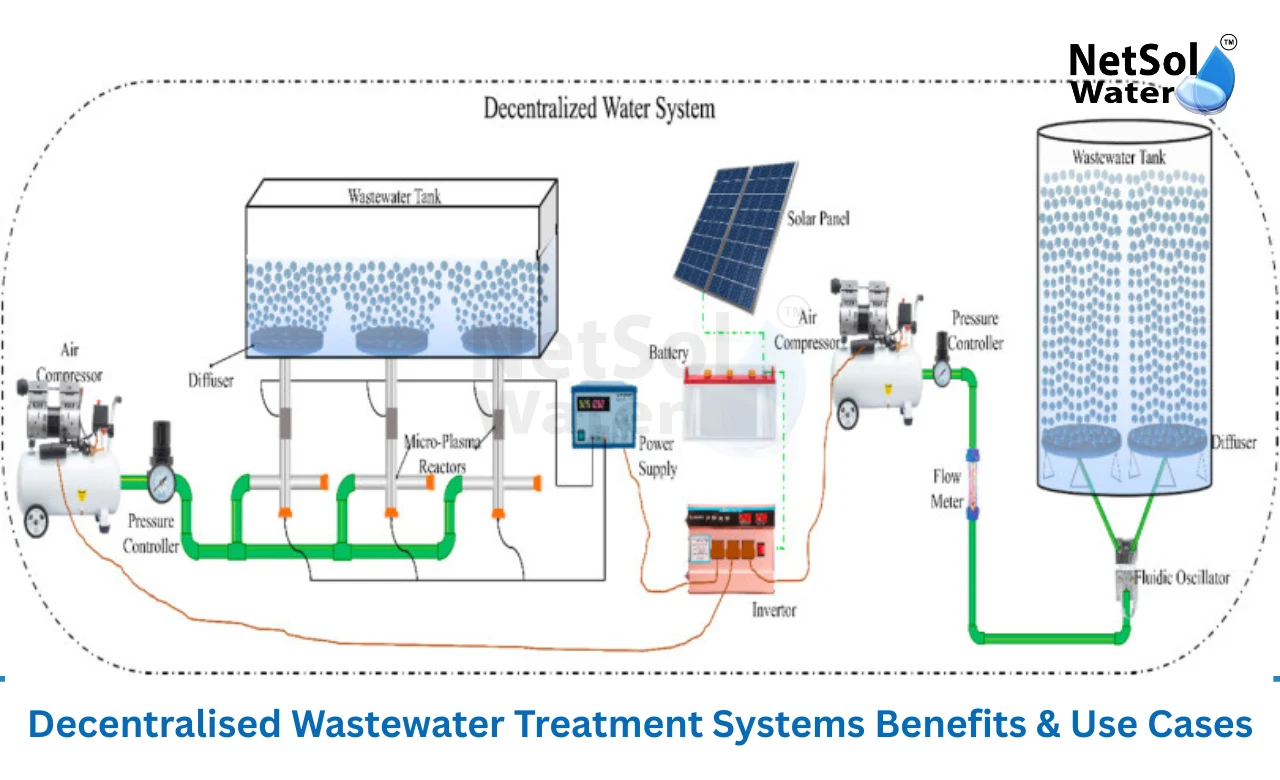

Role of state pollution control boards

State boards enforce the national laws on the ground. They issue the permits that allow a plant to operate. They inspect sites and take action when laws fail. Many state boards now run digital portals for consent and for tracking compliance. This makes the process faster but it also means data shows up quickly for audit. State boards may issue directions for city wise programmes. They can ask for cluster level treatment rather than single units for each factory. This approach changes the design and the scale of the Wastewater Treatment Plant that a municipality or an industry chooses. Local direction plays a part in the choice of technology and in the plan for operation and maintenance.

Incentives funding and project support

State and central schemes offer funds for upgrade works and for reuse projects. These funds lower the upfront cost of a modern plant. Subsidy support often comes for projects that target reuse of treated water for gardens or for industry use. Loans and technical support come through specific funds for clean city programs. These options speed up decision making by private owners and by local bodies. A manufacturer can guide a client through the funding steps and help write the technical part of a grant or loan application. Netsol Water provides technical packages that match funding criteria and that show the likely savings from reuse. This help can shorten the time to start work and to bring a new plant online.

Read some interesting information for Effluent Treatment Plant Manufacturer in Gurgaon

Conclusion

Regulatory pressure now pushes many public and private owners to upgrade their Wastewater Treatment Plant. The rules work at national and at state levels. They shape design choice operation plans and the path to reuse treated water. Netsol Water stands ready to help with design execution and long term support. If you plan an upgrade or a new plant reach out for a consultation.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com