Can we drink STP water?

Many cities now reuse treated wastewater to manage rising demand and shrinking freshwater sources. People often ask whether treated sewage water can replace normal drinking water. Urban areas face pressure on rivers and groundwater. Because of this pressure, many communities explore water recycling. We will explain what standard STP water can and cannot do.

Why Standard STP Water Is Not Drinkable

Knowing the limits of treated wastewater protects public health. We will explain why normal discharge from a sewage treatment plant does not match drinking water quality. Let us have a look at some main reasons and their impact.

1. Treatment Goals and Limits

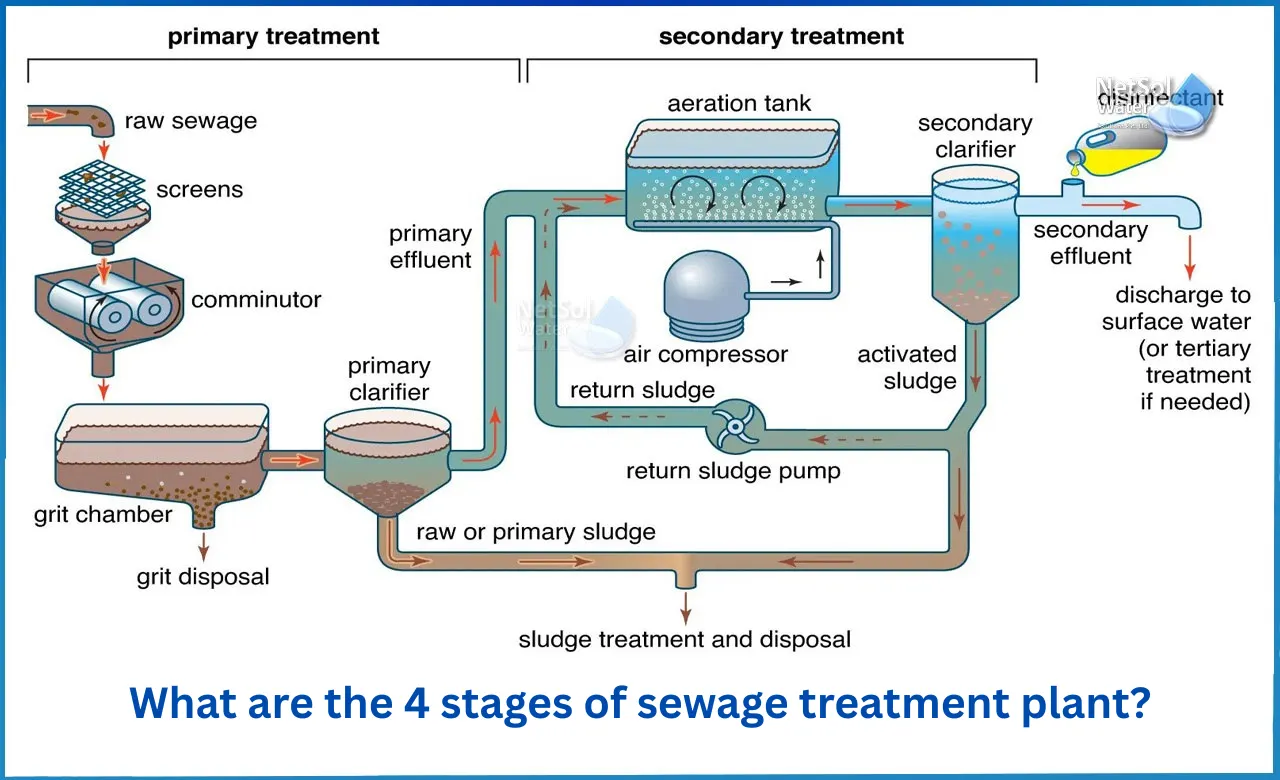

A sewage treatment plant mainly removes solids and reduces organic pollution. The system also lowers harmful microorganisms so water becomes safe for reuse activities. Normal treatment stages include screening, settling, and biological processes. These stages clean visible dirt and break down organic waste. After treatment, the water often appears clear and carries little odours. Even with this appearance, the water still holds dissolved chemicals and microscopic contaminants. Some viruses and resistant bacteria pass through regular treatment. Many pharmaceutical traces and household chemicals also remain in small amounts. These substances enter sewage from daily human use and industrial discharge. Standard systems do not fully remove them. Nutrients such as nitrates and phosphates also stay in the water. High nitrate levels create health risks, especially for children. Because of these remaining elements, standard STP water fails to satisfy drinking water limits in most regions.

2. Health and Regulatory Concerns

Health authorities demand strict testing before people can drink any water supply. They define limits for bacteria, viruses, and chemical residues. Normal Sewage Treatment Plant effluent usually does not reach these targets without added purification. Regulators also consider public confidence. Even when risk stays low, people hesitate to drink recycled water. Because of this concern, governments require several safety barriers. Typical STP designs do not include such high-level safeguards. Without these layers, direct drinking reuse becomes unsafe and also illegal in many areas.

How Standard STP Water Is Used Safely

Understanding safe reuse protects natural water sources. Let us have a look at some common reuse practices and their controls.

1. Non-Potable Reuse in Cities

Cities use treated wastewater for activities that do not involve drinking. Parks and gardens use this water for irrigation. Large buildings use it for toilet flushing. Municipal services use it for road washing and construction needs. This reuse reduces pressure on rivers and borewells. Authorities design separate pipelines for reused water. They label these pipelines clearly to avoid mixing with drinking water lines. Operators test quality often to confirm safety for nonpotable tasks. These controls keep exposure low and prevent health issues in daily urban operations.

2. Industrial and Agricultural Uses

Factories use treated wastewater for cooling and process work where drinking quality is not required. Agriculture also benefits from treated water when rules permit. Farmers use it for specific crops under controlled methods. Using Sewage Treatment Plant water in farms saves fresh water for homes. Crop type and irrigation method decide safety.

Making STP Water Drinkable

Changing wastewater into drinking water requires more than basic treatment. Let us have a look at some advanced methods and how they work together.

1. Advanced Treatment Technologies

Advanced treatment builds several layers of protection. Ultrafiltration removes fine particles and bacteria. Reverse osmosis pushes water through membranes to separate salts and dissolved chemicals. UV treatment destroys microorganisms and damages virus DNA. Advanced oxidation breaks complex organic compounds. Together these steps create water that meets drinking standards. Engineers also place prefilters to protect main membranes from damage. Sensors monitor flow, pressure, and clarity at each stage. Operators review results daily to keep performance stable. When these processes combine with constant monitoring, they deliver water that people can safely drink.

2. Regulatory Approval and Public Trust

Even strong technology needs legal and social approval. Regulators require performance records and safety audits before approval. They also demand backup systems to handle failures. Emergency response plans stay part of every potable reuse project. These requirements improve reliability. Public acceptance also matters. Authorities share data and explain processes so people understand water quality. Cities that use potable reuse invest in education programs.

Examples and Real-World Context

Real examples show how communities transform treated wastewater into a safe supply. Let us have a look at some global and local examples.

1. International Examples

Several countries operate large potable reuse plants. These projects use advanced treatment and strict quality checks. Engineers test water continuously and keep independent reviews. These programs strengthen water security and reduce stress on lakes and rivers. They also prove that treated wastewater can support cities during drought periods. These models guide other regions facing water shortages.

2. Local and Small-Scale Efforts

Some housing societies and institutions install advanced reuse systems on site. These plants treat wastewater to high quality and reuse it within the campus. Operators sometimes blend this water with other sources under rules. These local projects help develop technical skills and awareness. They also guide regulators while forming policies. Small-scale reuse shows how communities can manage water better with the right technology.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Faridabad

Conclusion

Water from a sewage treatment plant supports many activities, but people should not drink it without extra purification. Only advanced multi-stage treatment and strict control can convert treated wastewater into safe drinking water. Netsol Water is the leading sewage treatment plant manufacturer and offers guidance for reuse and treatment planning. If you want to understand how water reuse fits your project or community, you can connect with experts for advice. Reach out today to request a consultation and explore our solutions for safe reuse and future water security.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com