3 Best Effluent Treatment Plant Manufacturers in Ghaziabad

When managing industrial wastewater diligently, it would be quite essential to choose an authentic effluent treatment manufacturing plant. Ghaziabad is a growing industrial belt around Delhi where there has been growing demand of efficient and green process of effluent treatment. By choosing the ETP manufacturer your facility will not only comply with environmental gaming law, preservation of the surrounding environment and also will be able to reduce the operational cost.

Here, we are going to list the 3 best effluent treatment plant manufacturers in Ghaziabad and explain why they excel and how they contribute to sustainable industrial development.

3 Best Effluent Treatment Plant Manufacturers in Ghaziabad

1. Netsol Water

Being the top organization in the water treatment industry, Netsol Water has earned a reputation as one of the 3 best effluent treatment plant manufacturers in Ghaziabad. We are experts in designing and manufacturing ETP systems that are specifically meant to cater to the needs of various industries such as pharmaceuticals, textiles, food processing, and more.

Why Us?

- Tailor-made Solutions: We are not a believer in the one-size-fits-all approach. Our experts conduct customer consultations to determine the type of wastewater of the customers and develop ETPs that optimize the treatment efficiency.

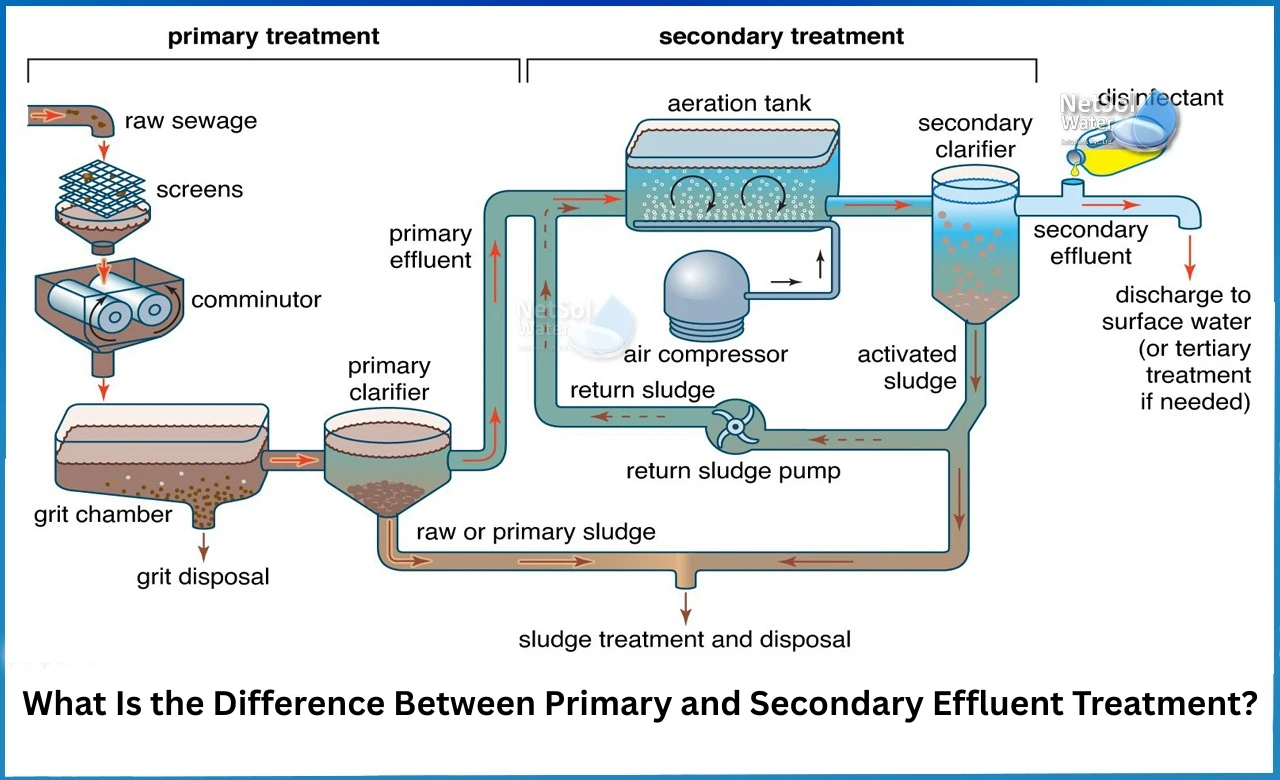

- Newest Technology: We employ newest treatment technologies including membrane bioreactors, activated sludge systems, and chemical treatment units to provide high-quality effluent.

- Compliance & Certification: Our facilities comply with all government regulations and environmental standards to help you avoid legal penalties and safeguard your corporate reputation.

- Effective After-Sales Support: We provide round-the-clock maintenance, technical support, and training to help your ETP run smoothly.

Netsol Water takes care of your effluent treatment needs in Ghaziabad with professional expertise, innovation, and environmental concern.

2. Enviro Solutions

Enviro Solutions is also a reputed manufacturer among the 3 best effluent treatment plant manufacturers in Ghaziabad. Enviro Solutions is involved in offering cost-saving ETP solutions focusing on sustainability and ease of use.

Key Strengths

- Environmentally Friendly Design: Their ETPs utilize green technology having lower chemical and energy consumption.

- Flexible Capacities: Ideal for small to large industry units.

- On-Time Project Completion: Enviro Solutions is famous for delivering projects within planned deadlines.

- Customer Training: They offer operational training to facilitate clients to run their plants efficiently.

Enviro Solutions offers service to various industries of Ghaziabad to empower companies with cleaner production and less environmental footprint.

3. GreenTech Water Solutions

GreenTech Water Solutions is an emerging name among the 3 Best Effluent Treatment Plant Manufacturers in Ghaziabad due to their innovative practices and quality focus.

What Makes Them Stand Out

- New Age Treatment Technologies: Application of new oxidation technologies, ultrafiltration, and biological nutrient removal.

- Aggressive R&D: Ongoing process development and research for new processes to enhance treatment of effluent.

- Single-Stop Solutions: They design, installation, commissioning, and maintenance under one roof.

- Focus on Energy Efficiency: Their solutions are low on power usage, keeping operational costs down.

GreenTech Water Solutions offers solutions to many industrial applications and has developed a good customer base within Ghaziabad and surrounding areas.

How to Select the Best Effluent Treatment Plant Manufacturing Company in Ghaziabad

Choosing between the 3 best effluent treatment plant manufacturers in Ghaziabad relies on a few factors:

- Experience and Expertise: Choose companies with experience of working successfully within your industry.

- Technology Provided: Select manufacturers that possess cutting-edge, energy-efficient, and eco-friendly treatment technologies.

- Customization: The manufacturer should design systems custom-fit to your wastewater profile.

- Compliance: Make sure that the manufacturer’s factories follow local environmental laws.

- Support and Service: Maintenance and prompt resolution of problems are indispensable to the plant’s longevity.

Why Ghaziabad Requires Quality Effluent Treatment Plant Manufacturers

Industrialization in Ghaziabad at a fast pace generates environmental issues, particularly in terms of wastewater discharge. Effluent, if not treated, can contaminate water bodies, cause damage to aquatic organisms, and affect public health. Ghaziabad industries, thus, must invest in good effluent treatment plants.

- Effective ETP manufacturers help industries

- Meet higher regulatory discharge standards.

- Lower polluting substances.

- Increase water reuse and resource recovery.

- Improve corporate social responsibility and sustainability.

If one chooses one of the 3 best effluent treatment plant manufacturers in Ghaziabad, it contributes to making the world a better, cleaner place.

Conclusion

Effluent treatment being successfully achieved is amongst the most important drivers of sustainable industrial growth in Ghaziabad. The 3 best effluent treatment plant manufacturers in Ghaziabad —Netsol Water, Enviro Solutions, and GreenTech Water Solutions—are industry leaders due to their innovative, client-specific, as well as regulatory-compliant solutions that address the particular requirements of different industries.

We’re among the privileged few at Netsol Water. We go on to facilitate Ghaziabad industries with functioning effluent treatment plants that are environmentally friendly along with increasing the business working efficiency.

Selecting a suitable ETP manufacturer is deciding the fate of your company and that of the planet. Enroll for responsible today through partnering with veteran experts of Ghaziabad.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473

Or write us at enquiry@netsolwater.com