What Every Company Should Know about Wastewater Reuse & Recycling

Wastewater reuse and recycling can cut costs and protect the environment. It can also help companies meet rules and show that they act responsibly. Cities and industrial areas around India face water stress. Companies in these places can gain from using treated water for cooling cleaning and landscaping. Choosing the right Wastewater Treatment Plant affects how well a reuse plan works. Netsol Water is the leading Wastewater Treatment Plant Manufacturer and it offers plants that match many needs.

Benefits and Importance of Reuse

Wastewater reuse brings strong benefits for the environment and for business stability. Companies that treat and reuse water cut their fresh water demand. They also reduce the cost of water purchase and of discharge fees. It can help secure permits and build good ties with local authorities. Let us have a look on some key benefits.

Environmental benefits

Companies that treat wastewater reduce the load on local rivers and drains. They lower the risk of pollution and harm to local wildlife. Treating water also cuts the need to draw water from lakes, rivers and underground sources. This helps protect those sources for future use. When a company reuses water it shrinks its effect on the local water cycle. This action also supports wider goals for resource saving and climate action. Many industries find that reuse helps them meet national and local environmental rules. This reduces the chance of fines and legal delays. A clear reuse plan makes it easier to share water with nearby partners in times of shortage.

Economic and social benefits

Reusing treated water can reduce the water bill and the cost of waste discharge. It can also lower the cost that the firm faces when rules tighten in the future. Firms may win new contracts by showing steady water management. Communities near the plant gain when companies cut pollution and protect local supplies. In some areas treated water can serve green spaces or be used in basic industrial tasks. This frees clean water for drinking and other needs. Over time the savings on water and on waste handling can outweigh the cost of a good Wastewater Treatment Plant. A strong reuse plan can also attract investors and partners who care about long term sustainability.

Design and Technical Considerations

A reuse project needs the right design and solid operation plans. The choice of technology affects safety cost and ease of use. Firms must match the treatment level to the use case. They must also plan for space energy needs and for future growth. Let us have a look on some major technical and logistic elements that decide project success.

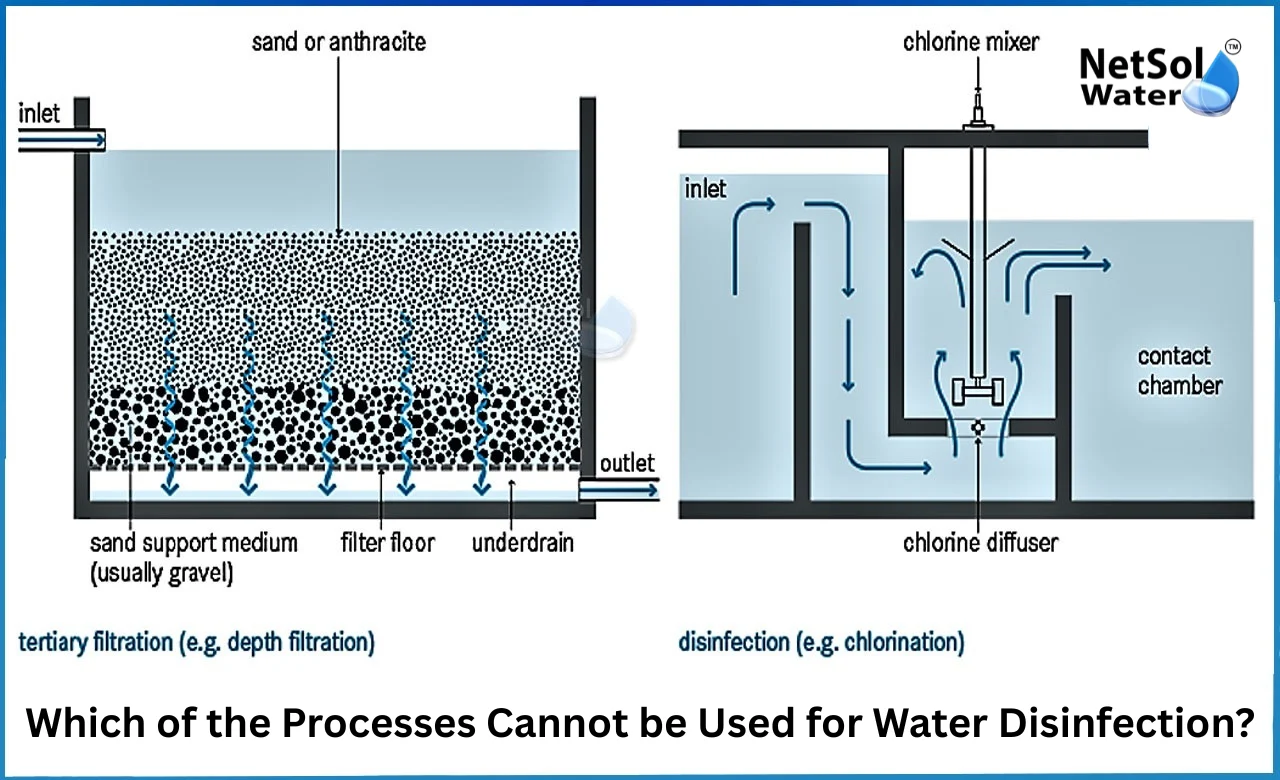

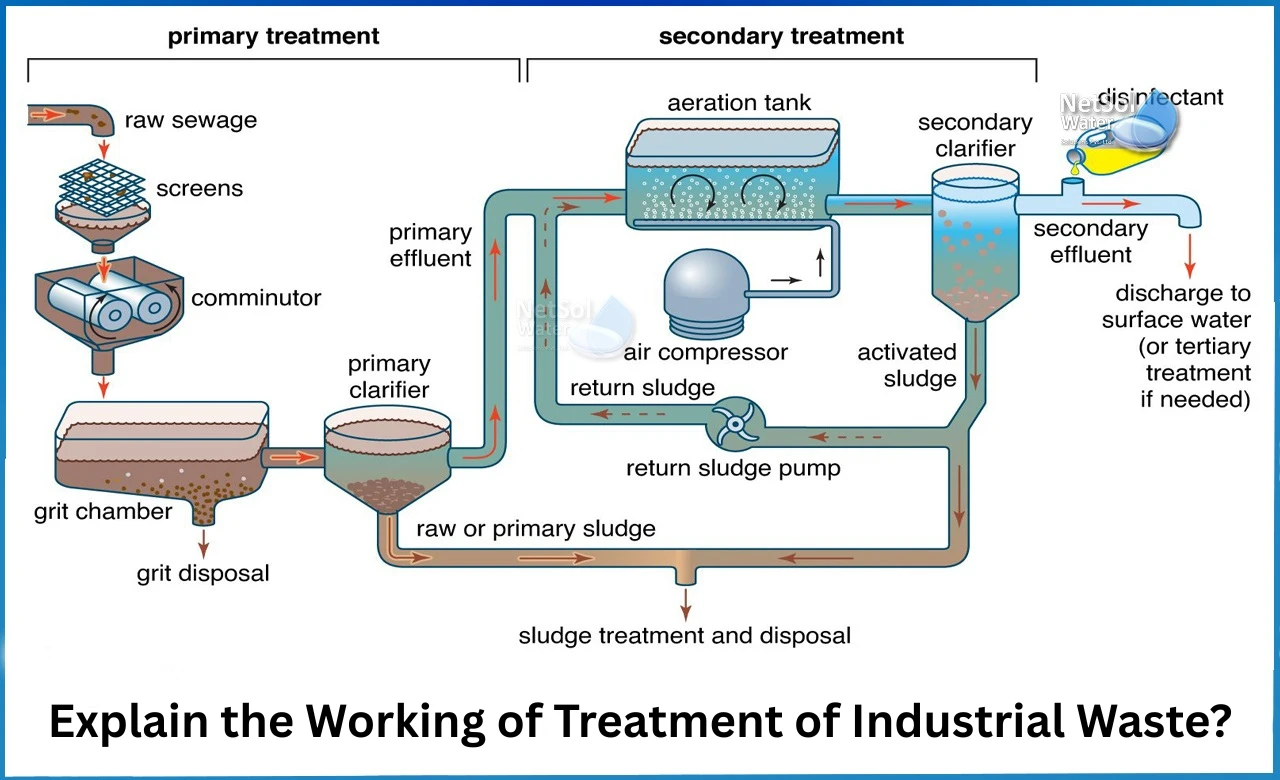

Treatment levels and technology choices

Design begins by setting the water quality target. Reuse for irrigation needs a different quality from reuse for cooling or for certain process uses. Companies must choose filters disinfectors and sometimes membrane systems. They must also plan for chemical dosing and for solids handling. The chosen technology must fit the waste type and the volume. It must also fit the site space and the power supply. Good design keeps the system simple to run. It also keeps running costs low. Firms should prefer modular systems that allow step by step upgrades. This approach helps match investment to need. When a company buys a Wastewater Treatment Plant it must ask about spare parts service and about training for its staff.

Operation, monitoring, maintenance and partnerships

Operation needs skilled staff clear schedules and good monitoring. Online sensors help track quality in real time. Regular maintenance prevents breakdowns and extends plant life. Companies can train their in house team or can sign a service contract. A reliable manufacturer can offer both parts and training and can support remote monitoring. Netsol Water is the leading Wastewater Treatment Plant Manufacturer and it offers service plans and training that help firms keep systems in strong working order. Good partnerships reduce risk and help firms reach reuse goals faster.

Read some interesting information for Effluent Treatment Plant Manufacturer

Conclusion

Companies that plan reuse need clear goals, good design and steady operation. A smart Wastewater Treatment Plant reduces cost and protects local water. It also shows that the company cares for the community and the natural resource base. Netsol Water can guide firms from design to steady operation. If you want help with a reuse plan or with a plant that fits your needs get in touch for more information or request a consultation today.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com