Before we proceed to to know the cost of STP plant, firstly we need to understand about what is STP plant mean?

What is STP full form?

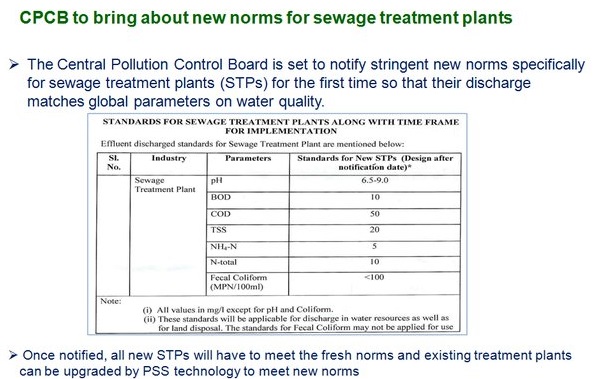

In the field of wastewater treatment plant STP Plant stand for Sewage Treatment Plant. It is a system that receives harmful water from commercial, industrial, & domestic sources and treat it for reusability, or safe discharge into nature as per CPCB norms.

What is Sewage Treatment Plant?

Sewage treatment plant in a wastewater treatment machine who is the combination of biologicals, mechanical equipment’s, and chemicals. This system uses this combine mechanism to treat the wastewater(Effluents) that is generated by commercial buildings, household, industrial or any other sources.

What is STP capacity?

STP (Sewage Treatment Plant) capacity is depend on the wastewater generated from its source or the premises size. and the cost of STP is also very much depend on its capacity and what technology it is uses for the treatment purposes.

The Size/Capacity of STP is listed below-

- 2 KLD STP Plant : This plant is used for small level wastewater generation facility. Up to 2000 Liters per day.

- 5 KLD STP Plant : This capacity of plant is used by commercial building, micro scale industry, where daily wastewater generation is Up to 5000 liters per day.

- 10 KLD STP Plant : This plant treatment capacity is 10,000 liters per day, used by Hotels, small scale industry, restaurant, commercial buildings, hospitals, small level schools, and so one.

- 20 KLD STP Plant : This plant facilitates user to treat wastewater up to 20,000 liters per day.

- 40 KLD STP Plant : It comes with a standard capacity of 40,000 liters of wastewater treatment per day.

- 50 KLD STP Plant : Best used for premises which generate effluent up to 50,000 liters per day.

- 100 KLD STP Plant : 1,00,000 liters per effluent treatment plant.

- 1 MLD STP Plant :

- 10 MLD STP Plant

- 50 MLD Wastewater Treatment Plant.

We as a leading renowned brand for sewage treatment plant manufacturer in India. We can design custom plant structure and capacity as per the site of the clients. We expert engineers visit at you site/location and can guide you about capacity of sewage treatment plant, size of STP plants and best suitable technology for you.

How to calculate capacity STP Plant

SIZE OF SEWAGE TREATMENT PLANT / CAPACITY OF SEWAGE TREATMENT PLANT (STP)

Before We start Calculating the size and capacity of STP calculate Total Domestic / Industrial / Commercial Raw Water Demand Required as per NBC-2005, Consider 135-150 LPCD.

- Total domestic (raw) water demand = TWD

- Estimated Sewage X = 90 % of TWD

- Estimate Sewerage X = 90/100 * TWD For Eg If TWD = 1500 KLD

- Capacity of S.T.P = 90 / 100 * 1500 KLD = 1350 KLD

- Space Requirement For 1350 Cum STP = let Assume, if total depth 3.30 Meter Included Free Board 300 MM (Standard Depth ) Liquid Depth L = 3.0 Meter

- Size Of STP = 1350/3 = 450 =450/15 (Breadth Assumed)= 30(Width) Total Space =15303= 1350 CUM

What is the cost of STP plant?

Sewage Treatment Plant is being an important part of new construction of commercial premises, industries or existing one’s as per directed by State and Central pollution control board. Depending on the plant size, capacity, and technology typical cost range is between 4 lakh to 80 lakh or in crore for sewage generation between 2000 liters to 1000000 liters per day or 2 KLD to 1 MLD.