STP Manufacturers in Greater Noida

STP Manufacturers in Greater Noida | Sewage Treatment Plant manufacturer in Greater Noida | Sewage Treatment Plant Manufacturer in Noida, Gautam Buddha Nagar, Netsol Water, 9650608473 NSWSPL is India’s biggest Compact Sewage Treatment Plant manufacturer with its head office in Greater Noida.

Noida lies close to the capital of India. It forms part of the National Capital Region and houses many industries, offices and residential buildings. With rapid development and a growing population, Noida generates a large volume of wastewater every day. This wastewater comes from homes, factories, offices and other places. If this wastewater flows untreated into water bodies, it pollutes rivers and harms health and the environment.

To avoid this situation, the city needs sewage treatment plants. These plants clean the wastewater before releasing it into rivers or using it for other purposes. The treated water becomes safe for reuse or disposal. As more buildings and factories rise in Noida, the need for these plants increases. That is where companies like Netsol Water come in. Netsol Water stands as a leading Sewage Treatment Plant Manufacturer in Noida. It manufactures systems that treat sewage and protect the city’s water resources.

Introduction to Sewage Treatment Plants (STPs)

Sewage treatment plants play a key role in cleaning wastewater. These plants remove harmful substances from sewage before releasing the water back into the environment. With more people and industries generating waste, cities need proper systems to manage and treat sewage. Without treatment plants, the wastewater would mix with clean water sources. That would lead to pollution and health risks.

What is a Sewage Treatment Plant?

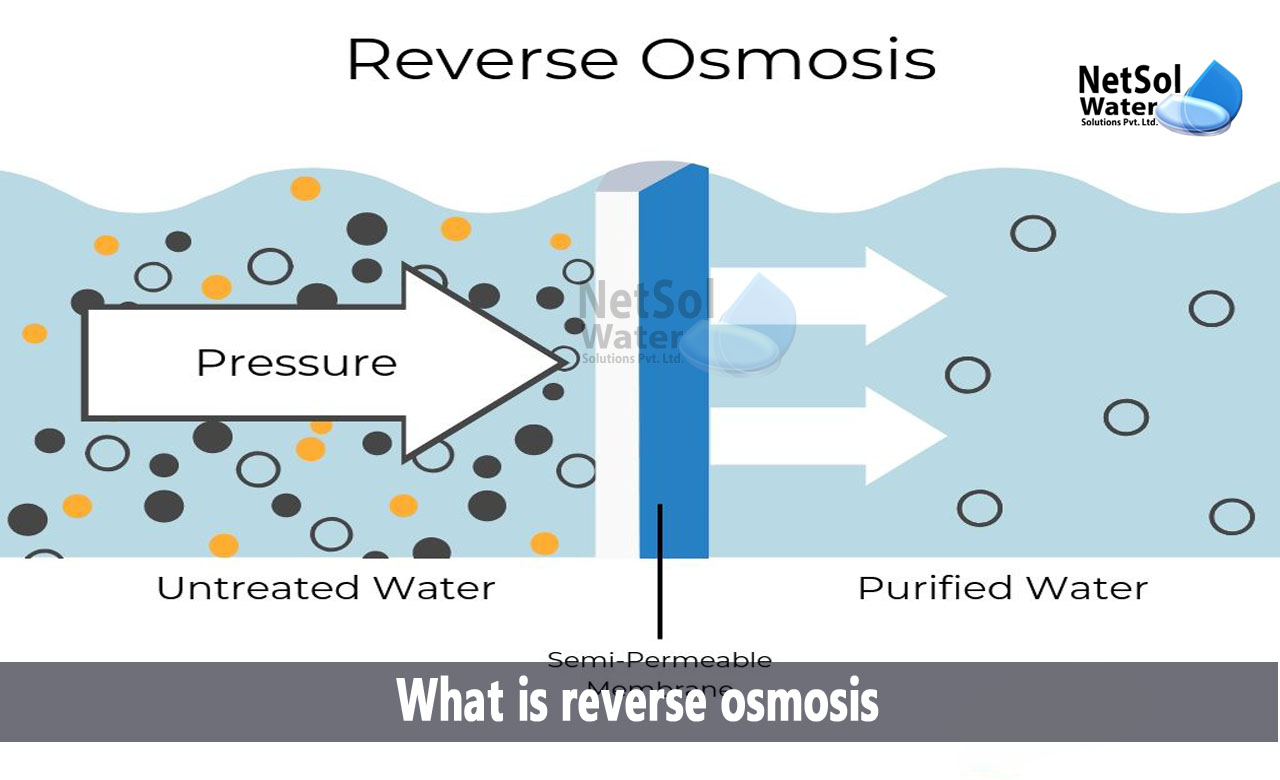

A sewage treatment plant is a system that cleans used water. This water comes from toilets, sinks, showers, factories and more. The plant treats this water using different steps. These steps help remove waste, dirt and harmful organisms. The goal is to make the water clean enough to go back to nature or get reused.

The process starts with removing large objects. Then it separates solid waste and treats the water with bacteria or chemicals. After the process finishes, the water becomes safe. These plants vary in size and design. Some treat water for small buildings while others handle waste from entire cities. Netsol Water is a leading Sewage Treatment Plant Manufacturer in Noida, providing advance solutions for waste water management.

Importance of STPs in Urban & Industrial Areas

Urban areas have high populations. These areas produce large amounts of sewage daily. Without proper treatment, the sewage can harm rivers and lakes. Industrial zones also produce chemical waste. If not treated, this waste can poison the soil and water. That is why sewage treatment plants are necessary.

STPs protect public health. They prevent waterborne diseases. They also protect aquatic life by keeping rivers clean. In many places, treated water gets used for gardening or flushing. That saves fresh water. So, these plants play an important role in both health and water conservation.

Best Sewage Treatment Plant Manufacturers in Noida

Noida houses several companies that build and install sewage treatment plants. These companies meet the growing demand for wastewater treatment in the city. Let us look at some leading manufacturers.

Netsol Water

Netsol Water is one of the most trusted names in the sewage treatment industry. It serves a wide range of clients from residential buildings to large industrial units. The company designs efficient and reliable systems. It follows a complete process from site analysis to final installation and training. Clients choose Netsol Water for its modern technology, strong after-sales service and quality systems that last long.

Thermax

Thermax is a well-known company with experience in water and wastewater treatment. It manufactures sewage treatment plants for various sectors. Thermax uses tested technologies and focuses on energy efficiency. Its systems are durable and suitable for industrial as well as municipal applications. Clients value its professional approach and timely project delivery.

Ion Exchange

Ion Exchange is another leading name in the field. It provides complete water treatment solutions. The company designs and installs STPs based on different needs. It uses both conventional and advanced technologies. Ion Exchange also offers strong service support and maintenance. Its plants serve industries, commercial buildings and housing societies.

VA Tech Wabag

VA Tech Wabag has global experience in designing and managing water treatment projects. It brings international expertise to local projects in Noida. The company handles both small and large-scale STPs. It focuses on sustainable practices and uses advanced systems. Its plants operate smoothly and meet strict discharge norms.

Triveni Engineering

Triveni Engineering offers a range of solutions in water treatment. The company has built a strong name through its performance and commitment. Its sewage treatment plants work well in residential and industrial setups. Triveni’s team ensures each plant meets client expectations and runs efficiently.

These manufacturers, including Netsol Water, help manage Noida’s wastewater. They offer different technologies and services based on the needs of the city and its industries.

Key Offerings of Top Manufacturers

A good manufacturer offers more than just machines. It provides complete solutions. Companies like Netsol Water build custom plants based on the client’s needs. They study the type and amount of sewage before designing the plant. They also take care of installation and training. Their systems are easy to use and maintain.

They also offer systems that save power and space. Their plants follow government norms. Good manufacturers give long-term support and guide clients at every step. That ensures the plants work well for years. These offerings make a big difference in performance and satisfaction.

Comparing Prices & Technologies

Prices for sewage treatment plants depend on many things. These include the size of the plant, type of treatment and level of automation. Some plants use basic methods while others use advanced systems. The technology used affects both cost and performance.

Some manufacturers offer low-cost solutions. But these may not work well in the long run. Good companies balance cost with quality. Netsol Water, for example, offers competitive prices while using tested technologies. They help clients choose the right system without overpaying. So it is important to compare not just price but also what the plant offers.

Types of Sewage Treatment Plants

Different types of sewage treatment plants use different methods. The type chosen depends on the kind of waste and the space available. Each type works in a different way. Let us have a look at some common types.

• Biological STPs

Biological sewage treatment plants use bacteria to clean the water. These bacteria eat the waste and break it down. The process happens in tanks. It may take some time but gives good results. This method suits places with regular domestic waste. It is safe and natural.

• Chemical STPs

Chemical sewage treatment plants use chemicals to remove impurities. They kill bacteria and help remove solids. This method works fast. It suits industrial areas where the waste has harmful chemicals. But it needs careful handling and proper storage of chemicals.

• Physical STPs

Physical plants remove waste using machines. They use filters, screens and settling tanks. These systems take out large solids and dirt. This method works well as a first step. Many plants use this method before other treatments. It is simple but must work with other systems for complete cleaning.

Which Type is Best for Your Needs?

Choosing the right type depends on many things. You must know the source and volume of sewage. For homes or offices, biological systems often work well. For factories, chemical or mixed systems may suit better. Space and budget also matter.

Manufacturers like Netsol Water help in choosing. They study your needs and suggest the best option. Their team explains the system and its benefits. So, getting the right type becomes easier with expert help.

How to Choose the Right STP Manufacturer?

Choosing the right manufacturer is important. A good company ensures the plant works well and lasts long. Let us have a look at some key factors to consider while choosing.

• Experience & Reputation: A company with more experience knows how to handle different cases. They understand client needs better. Reputation shows how well the company has served others. Netsol Water has built a strong name by serving many happy clients in Noida.

• Technology Used: The treatment system must use reliable technology. Outdated systems may not clean water properly. Good companies use modern systems that follow rules. They offer features like energy-saving and automation. This helps save cost and effort.

• After-Sales Support: After-sales service matters a lot. Once the plant gets installed, it needs checks and upkeep. A good company offers help even after the sale. Netsol Water provides service plans and training to ensure smooth working.

Cost vs. Quality Analysis

Low prices may seem attractive but may come with risks. A poor system can fail and cost more in the long run. It is better to choose a balanced option. A good manufacturer offers fair prices without cutting corners. That gives peace of mind and long-term value.

• STP Installation & Maintenance in Greater Noida

Installing and maintaining an STP requires planning and skill. Good companies follow a step-by-step process. They ensure the plant works well from day one.

• Step-by-Step Installation Process

First, the company visits the site. Then it checks the water quality and amount. Based on this study, they design the system. Once the design gets approved, the team starts building the plant. They set up tanks, pipes and machines. After this, they test the system. If everything works well, they hand it over. They also train staff to use the plant.

• Common Maintenance Challenges & Solutions

Every plant needs care. Filters can get blocked and pumps may stop working. Bacteria levels may drop. All these problems affect the plant’s performance. But timely checks solve these problems. Good manufacturers provide service support. They guide the team on how to spot and fix problems early. Netsol Water offers such support in Noida.

FAQs on Sewage Treatment Plants in Noida

People often have questions about STPs. They want to know about costs, time and rules. Let us have a look at some common questions.

What is the cost of an STP in Noida?

The cost depends on size, type and features. Small plants for homes may cost less. Large plants for industries cost more. On average, the cost can range from a few lakhs to several lakhs. Companies like Netsol Water offer cost-effective options.

How long does STP installation take?

The time taken depends on the size and design. Small plants may take a few weeks. Large systems may take months. A good company gives a clear timeline and sticks to it.

What are the govt. norms for STPs?

Government rules ask for proper treatment before releasing water. Plants must meet certain quality levels. They must get checked and approved. Good manufacturers know these rules and help clients follow them. Netsol Water manufactures plants that meet these norms.

Conclusion – Why Noida is a Hub for STP Manufacturers?

Noida has grown fast in recent years. It has many factories, buildings and offices. All these places need water treatment. That is why there is a high demand for sewage treatment plants. The city also has skilled workers and companies like Netsol Water. Netsol Water leads the market as a trusted sewage treatment plant manufacturer in Noida. It offers smart solutions and helps the city manage its waste better.

If you want to know more or plan to install a plant, contact Netsol Water. They will guide you and offer the best solution. Talk to their experts today and keep your water clean.

Connect with Us

Netsol Water works to bring clean water back to nature. We stand as a Sewage Treatment Plant Manufacturer in Noida you can trust.

Request a Quote

Send an email at enquiry@netsolwater.com with your flow and site info. We send a clear plan and price within a day or two. Or

Book a Site Visit

Our expert visits to measure and suggest. We use mobile tests to log your water profile on spot. Just call +91-9650608473 to connect.