Reverse osmosis (RO) produces clean, great-tasting water and is widely regarded as one of the most efficient water filtration techniques. Numerous uses for RO systems exist, such as faucets, whole-house, aquariums, and restaurant filtration. Whatever the initial quality of your water, there is probably an RO system that will work for you.

Reverse osmosis: What is it?

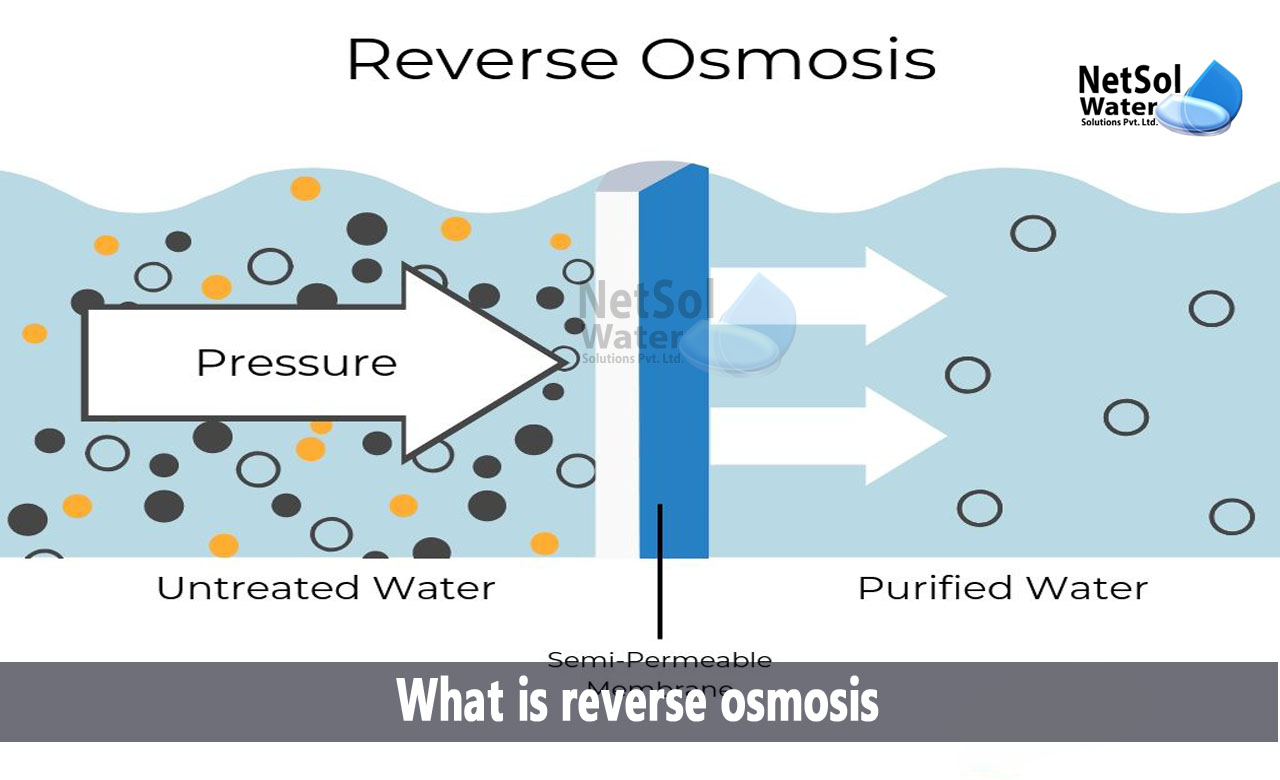

When pressure pushes water through a semipermeable membrane, reverse osmosis eliminates pollutants from unfiltered water, or feed water. To produce clean drinking water, water flows from the more concentrated side of the RO membrane—which has more impurities—to the less concentrated side—which has fewer contaminants. The permeate is the name for the produced fresh water. Waste or brine is the term for leftover concentrated water.

Small pores in a semipermeable membrane allow for the passage of water molecules but impede the passage of pollutants. Osmosis involves the concentration of water as it moves through the membrane to achieve equilibrium on both sides. However, reverse osmosis prevents pollutants from passing through the membrane’s less concentrated side.

Let’s use what we now know about reverse osmosis to analyze a real operational plant.

The entire reverse osmosis procedure, including the pretreatment and post-treatment that are typically necessary for heavily contaminated water, is described as follows:

- Pre-chlorination dosing system:

The media filter will be able to filter the majority of it if the supply water is contaminated or includes traces of heavy metals. It is strongly advised to dose some chlorine to convert the dissolved heavy metals to physical form.

- Tank for storing raw water:

Most reverse osmosis systems begin with a sizable tank that holds the polluted water, while some RO Systems can draw water directly from a well or pipe feed. Having a large storage tank for your intake water is an easy approach to ensure that your pump lasts as long as possible. Not having enough feed water can harm a pump.

- Feed Water Pump:

The treatment system receives its initial pressure from a commercial or industrial pump. The RO membranes and any pretreatment are often passed through this motor’s sufficient water pressure, but if they aren’t, a booster pump may be required later on.

- Media or Multi-Layer Filter:

Even while we hate to acknowledge it, some items can’t be purified by membranes. Reverse osmosis is unable to remove particles that dissolve too well in water, such as nitrates, a frequent pollutant present in fertilizers and animal manure. Reverse osmosis typically doesn’t work to eliminate things like bad taste and odor. Media that especially targets the items your RO system can’t catch can be put in a multi-layer filter. A multi-layer filter is necessary if these pollutants are to be removed.

- Filter with activated carbon:

To eliminate organic contaminants, unpleasant tastes and odors, and chlorine from the water, activated carbon filters are a suitable option.

- Chemical dosing system for anti-scalant:

We employ anti-scalant dosing systems to provide our anti-scalant RO chemical, which aids in preventing membrane fouling.

- System for Reverse Osmosis:

We have our reverse osmosis system at last. A booster pump will normally be required right before this phase, if at all. The reverse osmosis system can generate a significant amount of waste and up to one million gallons of product water per day from a continuous inflow. Although it can typically be poured down the drain, check with your local water authority to see whether special handling is required.

- Storage tank for product water

The reverse osmosis system’s permeate often drains into a sizable tank where it is stored until needed. If it didn’t, it would be necessary for the system to be on in order to have access to fresh water, which is sometimes problematic. In addition to being utilized in many of the typical industries or applications, an RO system may also be used to pump water straight into a well or aquifer for recharge.

- System for Post-Chlorination Dosing:

It is strongly advised to inject some chlorine into the permeate water if it will be kept for more than a day in order to keep it clean and free of contaminants.

- Water Pump:

The permeate water is repressurized by this pump until it is no longer usable. This is chosen based on the required head and overall distance to travel. The permeate water must not be contaminated, hence stainless steel must be chosen for this pump.

- UV Sterilizer for product water:

The UV sterilizer is used as the last line of defense against infection after the storage tank. Most of the time, we either employ UV sterilization or post chlorination as a disinfection agent.

How Netsol helps!

We offer a wide choice of reverse osmosis and water treatment systems to fit your demands. Netsol has years of experience as a global provider of water treatment solutions for a number of applications and industries. Our ability to pre-engineer and modify water treatment and reverse osmosis systems to match a variety of customer requirements and specifications is made possible by Netsol’s significant global experience in engineering and manufacturing.

For any support of inquiries, or product purchases and related services call on +91-9650608473 or email at enquiry@netsolwater.com

One comment

Pingback: Different Types of Commercial RO Systems and Capacity

Comments are closed.