Zero Liquid Discharge Systems

Water scarcity pushes industries to seek innovative solutions for water management. Zero Liquid Discharge (ZLD) systems stand at the forefront of water conservation as they transform industrial wastewater into reusable resources. These systems block liquid waste from entering the environment while extracting valuable materials from wastewater streams. Industries now face strict environmental regulations that drive businesses to find ways to decrease their water usage. ZLD systems excel by establishing a closed-loop process that enables water to cycle through multiple times. This method preserves water resources and helps organizations achieve environmental compliance standards.

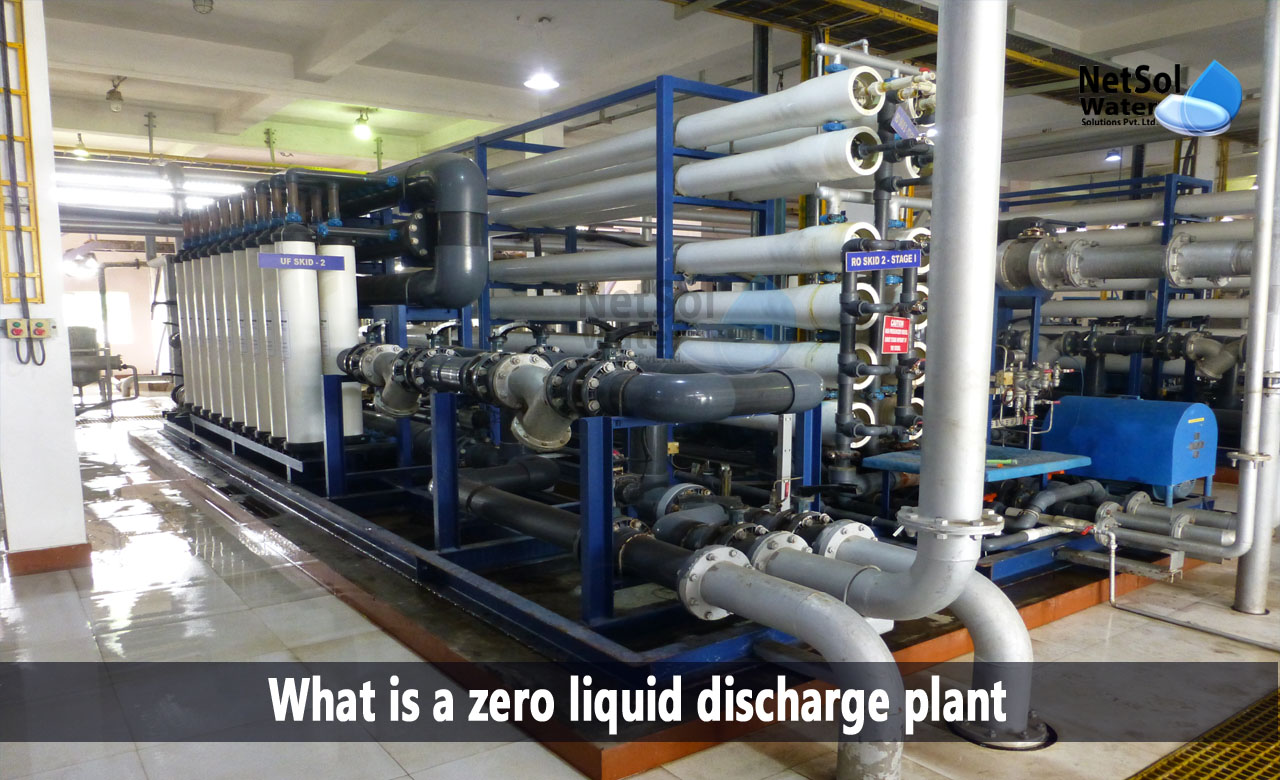

The Core Components of Zero Liquid Discharge Systems

ZLD systems feature advanced components that unite to process wastewater thoroughly. These components establish a connected sequence that processes wastewater step by step until it eliminates all liquid waste. Let us discover the fundamental elements that build a typical ZLD system.

1. Pre-treatment Units: The pre-treatment phase starts as screens and filters catch large particles and debris. Advanced filtration systems pass water through multiple stages to remove particles of varying sizes before sending clean water to subsequent phases. The clarification tanks hold wastewater while suspended solids sink to the bottom and specialized chemicals pull oils and other contaminants from the water stream. This stage adjusts pH levels to create the best conditions for upcoming treatment steps.

2. Membrane Systems: The membrane filtration stage uses specific membranes to extract dissolved solids. Ultrafiltration membranes stop smaller particles while reverse osmosis systems drive water through special membranes to separate dissolved salts and impurities. The membrane process concentrates wastewater in multiple stages to prepare it for evaporation.

3. Evaporation and Crystallization: Heat processes work to separate pure water from dissolved solids in the concentrated wastewater. Mechanical vapour recompression evaporators apply heat and pressure to turn water into steam, which leaves a concentrated solution behind. The crystallisation units then process this solution to form solid crystals. These crystals pack valuable materials that industries can extract and use again in their operations.

The Economics and Environmental Impact of Zero Liquid Discharge Systems

ZLD systems deliver economic benefits while protecting natural resources. More industries choose these systems because they serve both financial and environmental goals. Let us examine how ZLD systems impact business operations and environmental protection.

- Operating Cost Considerations: Companies must invest upfront in ZLD systems but gain ongoing savings through continuous water reuse. The design of each system and the type of wastewater determine energy usage patterns. Modern ZLD systems include energy recovery tools that capture and reuse heat throughout different processes. Industries often find that recovering materials from wastewater helps pay for operations and creates additional income streams.

- Environmental Benefits: ZLD systems work to decrease industrial environmental impact significantly. These systems shield water ecosystems by stopping contaminated water from flowing into natural water sources. The water recovery process lessens the strain on freshwater supplies that support local communities. Many industries achieve water independence through ZLD systems, which eases demands on city water systems.

Future Developments and Industry Applications

ZLD technology grows more advanced as it spreads across different industries. Improvements in system design and efficiency bring ZLD systems closer to reaching more business sectors.

- Technological Advances: Engineers work to create more energy-efficient parts for ZLD systems. New membrane materials boost filtration while using less energy. Smart control systems and automation make operations smoother by cutting down manual work and improving system results. These improvements make ZLD systems easier to afford and operate.

- Industry-Specific Solutions: Each industry needs ZLD solutions that match their specific wastewater makeup. Power plants use ZLD systems to clean cooling tower water and boiler waste. Textile makers install these systems to process water-containing dyes and recover useful chemicals. Food and drink producers employ ZLD technology to clean water with high organic content and reuse it in non-food areas.

Take the Next Step Toward Sustainable Water Management

Zero Liquid Discharge Systems show the path to sustainable industrial water management. Our water treatment specialists want to show you how ZLD systems can improve your operations. Connect with us to explore your needs and discover how to bring a Zero Liquid Discharge system to your facility. We conduct thorough assessments to understand your requirements and create solutions that match your business objectives.

To explore customised commercial RO plants, Industrial RO plant, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473

Email: enquiry@netsolwater.com