Zero Liquid Discharge (ZLD) Systems – Gurgaon’s Top ETPs

Gurgaon’s rapid growth brings a growing need to manage industrial wastewater in a way that protects local water bodies. Zero Liquid Discharge systems deliver a path to recycle and reuse every drop of wastewater. Effluent Treatment Plant Manufacturers design these plants to meet strict environmental rules. Netsol Water has earned its place as a leading Effluent Treatment Plant Manufacturer in Gurgaon by offering reliable ZLD solutions that match Gurgaon’s industrial needs. ZLD systems matter because they eliminate any discharge of liquid waste. As industries expand in Gurgaon they must handle rising wastewater volumes.

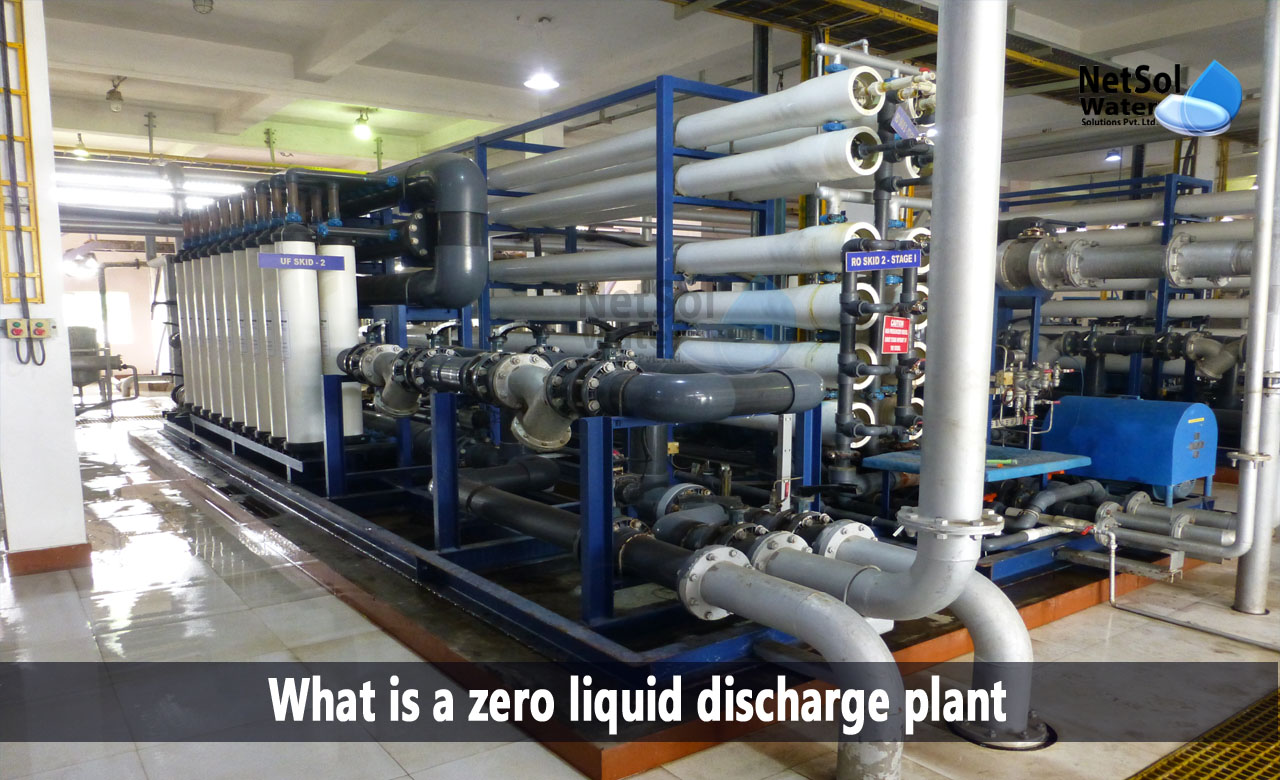

Zero Liquid Discharge Systems

Importance of ZLD in Industrial Growth

ZLD systems play a key role in supporting Gurgaon’s factories and plants. They ensure no untreated water leaves the site. This protects rivers and groundwater from harmful chemicals. As a result industries can expand without harming the environment. Let us have a look on some core elements of ZLD systems.

Wastewater Collection and Pre-Treatment

ZLD begins with gathering wastewater from production units. Pretreatment removes large solids and oil traces. Screens and grit chambers separate coarse particles. Oil-water separators handle oily effluent. This stage sets the stage for efficient downstream processes. Pretreatment also uses equalization tanks. These tanks balance flow rates and pollutant levels. A steady feed into the main treatment units prevents shocks to membranes and evaporators. Proper pretreatment cuts maintenance needs and prolongs equipment life.

Membrane Filtration

After pretreatment the water moves through membranes. Ultrafiltration and RO membranes block dissolved solids. They yield a clean permeate and a concentrate rich in salts. This concentrate then heads to evaporation units. Membrane filtration offers high removal rates for organic matter and salts. Membranes work under pressure. Operators must control pressure levels to avoid damage. Regular cleaning protocols prevent fouling. A robust membrane plan ensures consistent performance and lowers operating costs.

Evaporation and Crystallization

The concentrated brine from membranes enters evaporators. Here heat drives off water as vapor. Vapor condenses into pure water that returns to plant use. The remaining brine grows even more concentrated until salts crystallize. Crystallizers handle salt recovery. They produce solid salts that industries can sell or dispose of safely. This stage completes the ZLD cycle by leaving zero liquid waste.

How ZLD Protects Water Resources

ZLD prevents pollutants from entering natural water bodies. It turns wastewater into a resource. Recovered water can feed boilers cooling towers or process lines. Solid salts may find use in chemical industries. This circular approach cuts freshwater demand and disposal fees. By adopting ZLD Gurgaon industries show environmental leadership. They secure social license to operate. They also avoid fines linked to wastewater violations.

Key Benefits of ZLD Systems

Water Conservation and Cost Savings

ZLD systems deliver high water recovery. Plants can reuse over 95 percent of their wastewater. This reduces freshwater purchases. It also lowers effluent discharge fees. By reusing water on site companies cut their utility bills. They also reduce dependence on municipal supplies. This proves vital in water-stressed regions like Gurgaon.

Regulatory Compliance and Risk Reduction

Gurgaon industries face strict rules from pollution control boards. ZLD ensures no liquid discharge so plants stay within legal limits. This reduces the risk of fines and shutdowns. It also shields companies from reputational damage tied to environmental incidents.

Resource Recovery

ZLD turns waste into value. Crystallized salts can serve as raw materials. Recovered water feeds cooling systems and boilers. This resource recovery creates new revenue streams. It also aligns with circular economy goals embraced by modern industries.

Operation and Maintenance Practices

Routine Monitoring and Control

ZLD systems need constant supervision. Netsol Water equips plants with online sensors for pH conductivity and flow. Automated control loops adjust pressures and temperatures in real time. This proactive control maintains steady performance.

Scheduled Cleaning and Servicing

Membrane fouling can reduce efficiency. Netsol Water implements cleaning-in-place protocols. Pumps valves and heat exchangers also follow preventive maintenance schedules. Regular servicing avoids unexpected downtime and extends plant life.

Training and Support

A well trained operations team is important. Netsol Water provides on-site training for plant staff. They cover system operation troubleshooting and safety. They also offer remote support via data links. This ensures expert help is always available.

Why Choose Netsol Water as Effluent Treatment Plant Manufacturer in Gurgaon

Let us explore why to choose Netsol Water as Effluent Treatment Plant Manufacturer in Gurgaon.

Proven Track Record

Netsol Water has delivered numerous ZLD projects in North India. Their Gurgaon installations boast over 95 percent water recovery and zero non-compliance events.

Customized Solutions

They customise each design to site needs. Their modular approach speeds up installation and reduces civil work.

Local Service Network

With offices near Gurgaon Netsol Water offers fast response for spare parts and service calls. Their team knows local regulations and climate factors.

Commitment to Innovation

They invest in pilot testing new membrane materials and energy recovery systems. This keeps Gurgaon clients ahead in efficiency and cost savings.

Conclusion

Effective wastewater management shapes Gurgaon’s sustainable growth. Netsol Water stands out as the leading Effluent Treatment Plant Manufacturer in Gurgaon by delivering reliable ZLD solutions that ensure compliance. To explore how a ZLD system can transform your plant reach out to Netsol Water today for a consultation or more information.

Phone: +91-965-060-8473

Email: enquiry@netsolwater.com