Sustainable Wastewater Management in Textile & Dyeing Industries

Textile and dyeing industries give work to many families and drive small business growth. This activity uses large volumes of water every day. After dyeing and washing the water contains strong color, salts and chemical residues. If industries release this water without treatment they harm rivers ground water and farm fields. Sustainable methods help protect nature and keep business stable. A reliable Wastewater Management System helps factories meet rules save water and cut costs. Netsol Water is the leading provider and Effluent Treatment Plant Manufacturer of solutions that guide textile units to manage wastewater with care. This company helps plants use less fresh water lower discharge and improve their environmental image. Good practice does more than stop pollution. It opens chances for reuse energy savings and long term savings.

Wastewater Challenges in Textile and Dyeing Industries

We will explain why textile wastewater poses a real challenge. Industry owners must know the problem before they choose treatment steps. Let us have a look at some key aspects and their impact.

Nature of Textile and Dyeing Wastewater

Textile wastewater carries strong color and dissolved salts that do not break down easily. Dye molecules block sunlight in water bodies and harm aquatic plants. Process water also shows high temperature and wide pH shifts. These factors slow natural breakdown and reduce the options for simple biological treatment. Many dyes resist normal microbes and need extra methods to change their structure. Waste streams also contain surfactants and finishing chemicals that affect oxygen levels in rivers. When factories mix different process waters the load on treatment units goes up. This makes design and operation harder. A planned Wastewater Management System starts with understanding these flows. The system must separate heavy solids balance pH and prepare water for biological or chemical steps. Without this work advanced filters and membranes face early clogging. Good design extends equipment life and reduces the risk of untreated discharge.

Environmental and Business

Impact Polluted water seeps into ground water and reaches farms. Local people face health issues and reduced crop yields. Authorities monitor river quality and they enforce limits on discharge. Factories that fail to meet limits face fines or closure. Buyers now prefer vendors who follow clear environmental norms. This shift makes sustainable practice a market need. A strong Wastewater Management System helps factories keep operations running and build trust with customers. The system also enables reuse of treated water for washing and cooling. Reuse cuts fresh water use and lowers operating costs. Over time the savings often cover the system investment. In short a well planned approach protects the environment and supports the business case for long term growth.

Sustainable Treatment Solutions for Textile Wastewater

Let us have a look at some proven methods and how to use them in daily operation.

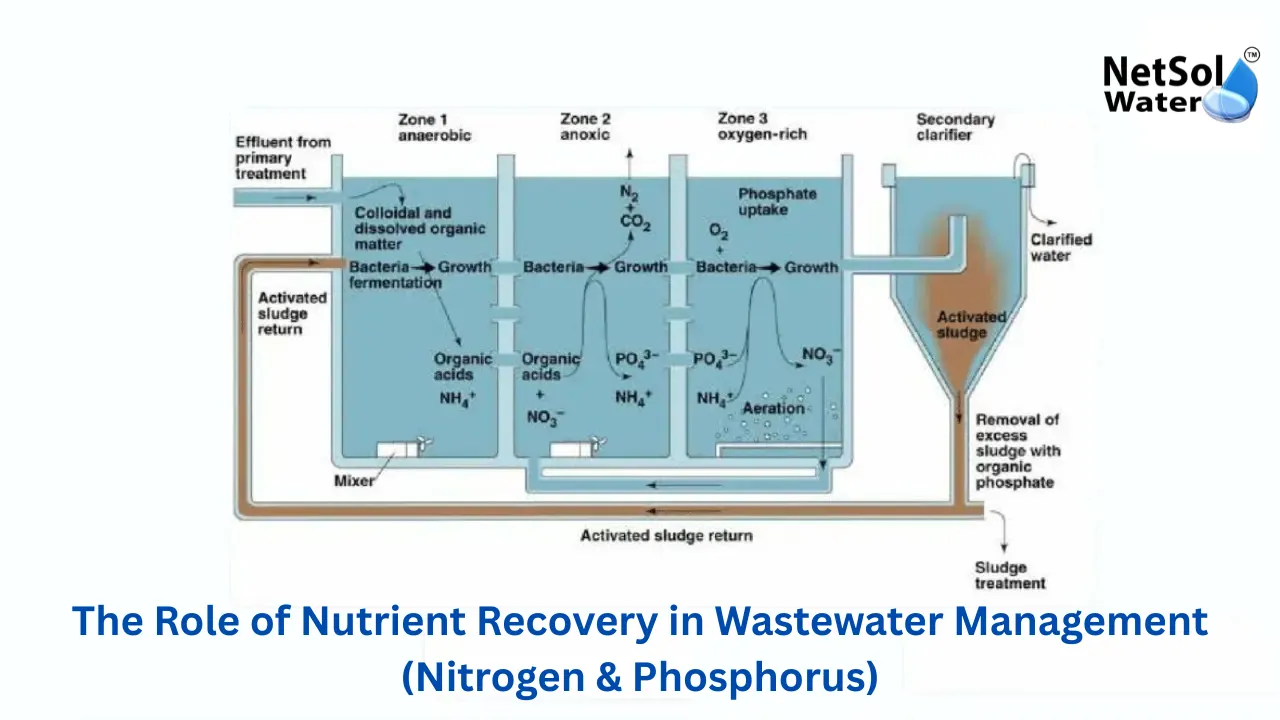

Primary and Secondary Treatment Importance

Primary treatment lays the base for all later steps. It removes heavy solids and evens out flow and pollutant load. Equalization reduces shock loads on biological units and makes treatment stable. Settling tanks and coarse screens protect pumps and membranes from abrasion. After primary steps the process moves to secondary treatment. Secondary treatment uses microbes to break down organic matter and reduce biochemical oxygen demand. When operators control oxygen and temperature microbes perform well and they lower the organic load effectively. Good secondary systems keep sludge production predictable and they lower the cost of disposal. A reliable Wastewater Management System combines primary and secondary stages so each stage does not strain the next one. This integration reduces maintenance and improves the lifetime of the full system. Proper monitoring helps operators tune aeration and retention times to reflect real loads.

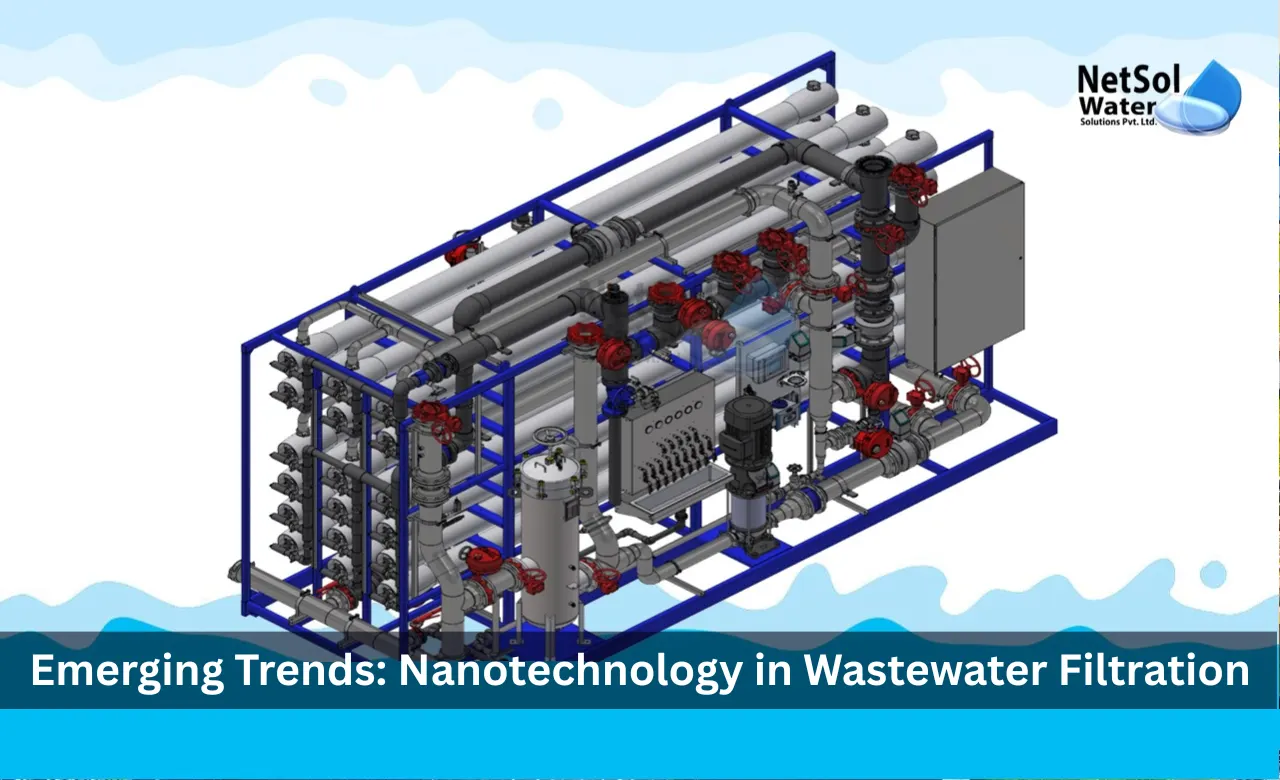

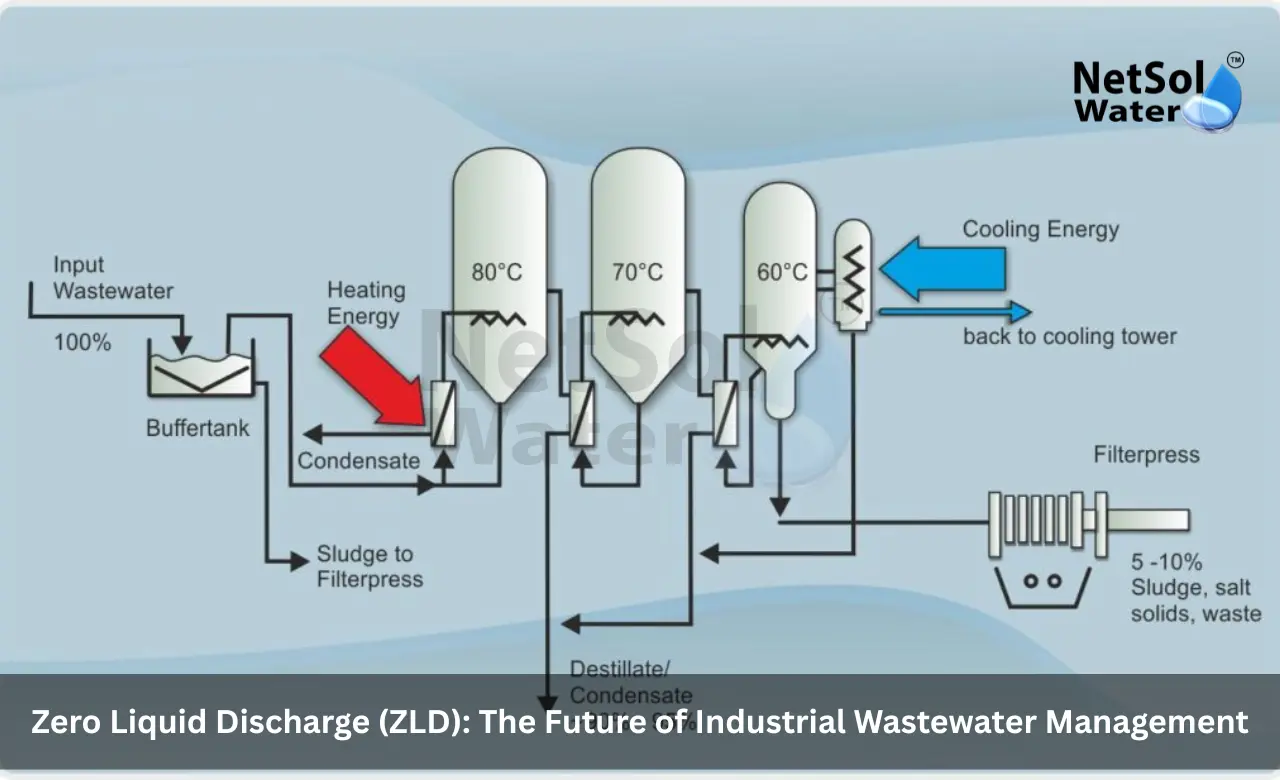

Advanced Treatment and Water Reuse

Advanced treatment removes color, dissolved salts and micro pollutants that remain after biological steps. Technologies such as coagulation and activated carbon adsorption cut color and smell. Membrane processes like ultrafiltration and reverse osmosis separate fine particles and dissolved salts. When factories aim to reuse water for processes they must add polishing steps and disinfection. Treated water can return to washing lines dyeing machines and cooling towers. Reuse reduces fresh water demand and eases pressure on ground water. It also lowers the volume of discharge that needs further handling. A smart Wastewater Management System allows staged upgrade so plants add advanced units when they need more reuse. Netsol Water is the leading company and Effluent Treatment Plant Manufacturer that helps industries plan reuse paths and choose the right combination of filters membranes and polishing steps. This approach keeps costs low and allows gradual investment as the plant grows.

Role of Compliance and Smart Operation

Let us have a look at how to meet norms and keep performance steady.

Meeting Pollution Control Norms

Regulators set clear limits for parameters such as biochemical oxygen demand, total suspended solids and heavy metals. Plants must test and record results and they must submit reports to the pollution control board. Regular sampling helps spot trends and avoid sudden non compliance. A Wastewater Management System must include online monitors and manual testing points so operators can act fast when quality shifts. Proper record keeping also helps in audits and buyer checks. Meeting limits builds trust with the local community and it lowers the chance of legal action. Factories that adopt monitoring and rapid response avoid many costly interruptions.

Operation Training and Support

Even the best equipment fails if people do not operate it well. Training operators on daily checks troubleshooting and preventive maintenance keeps plants reliable. Simple steps such as cleaning screens checking pumps and balancing chemicals prevent most faults. Scheduled maintenance extends the life of membranes pumps and blowers. Support from the equipment provider helps during start up and when the plant faces unusual loads. Netsol Water is the leading provider that gives training and service plans to help factories run systems without stress. This support reduces downtime and ensures that the Wastewater Management System keeps delivering results.

Read some interesting information for the Industrial RO Plant Manufacturer in Delhi

Conclusion

Sustainable wastewater practice protects rivers, saves water and supports business continuity. A planned Wastewater Management System helps textile and dyeing units meet rules reduce cost and build a stronger brand. Netsol Water is the leading partner and Effluent Treatment Plant Manufacturer for firms that need clear and practical solutions. For more information and to request a consultation contact experts who can assess your plant and propose the right steps. Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com