Top Sewage Treatment Plant Manufacturers in Noida

Noida, a rapidly growing industrial and commercial hub in Uttar Pradesh, is home to many leading manufacturers of water treatment plants and sewage treatment plants. These companies provide advanced solutions for industries, municipalities and commercial organizations, ensuring efficient water purification and wastewater management. Among the top companies in this sector, Netsol Water stands out as a trusted top sewage treatment plant manufacturer in Noida, offering compact sewage treatment plants, modular sewage treatment plant systems, and underground sewage water treatment plants.

Why Are Sewage Treatment Plants Essential in Noida?

With rising population density, industrial activities and strict environmental regulations, untreated sewage can lead to:

- Water pollution (contaminating rivers like the Yamuna)

- Health hazards (spread of diseases)

- Groundwater depletion & contamination

- Legal penalties for non-compliance with pollution control norms

A well-designed sewage treatment plant helps in:

- Recycling water for landscaping, flushing, and industrial use

- Reducing environmental pollution

- Complying with CPCB (Central Pollution Control Board) & UPPCB norms

- Lowering freshwater consumption

Why Choose Noida-Based Sewage Treatment Plant Manufacturers?

Noida-based manufacturers specialize in modern sewage treatment plants that incorporate aerobic treatment, advanced membrane filtration, and pre-fabricated sewage treatment plant designs. These systems are designed to handle a wide range of sewage water with simple controls, ensuring ease of operation and low operational cost.

Key Features of Sewage Treatment Plants in Noida

- Compact & Modular Systems: Ideal for space-constrained areas, these compact water treatment plants can be easily installed and expanded.

- Underground & Pre-Fabricated Options: Suitable for urban areas where space is limited.

- Aerobic Treatment Technology: Ensures high-quality effluent output, meeting environmental standards.

- Advanced Filtration: Incorporates membrane filtration for superior water purification.

- Customizable Solutions: Manufacturers provide a complete range of systems tailored to different water source types.

Leading Sewage Treatment Plant Manufacturers in Noida

Several reputable STP manufacturers in Noida offer advanced wastewater treatment solutions. These companies specialize in:

- Industrial STPs (for factories, pharma, textiles, etc.)

- Commercial STPs (malls, hotels, hospitals)

- Residential STPs (apartments, townships)

- Compact & modular STPs (for space-constrained areas)

1: Netsol Water

A prominent name among water treatment plant manufacturers, Netsol Water offers innovative sewage treatment plants with a focus on sustainability. Their modular system designs ensure scalability, while their pre-fabricated sewage treatment plants reduce installation time.

Key Offerings:

- Compact sewage treatment plants

- Underground sewage water treatment plants

- Low operational cost solutions

- Quick delivery time

Industries Served:

- Hotels & Resorts

- Hospitals & Institutions

- Industrial Effluent Treatment

- Municipal Corporations

2: Sewage Treatment Plants

A leading sewage treatment plant manufacturer in Noida, Sewage Treatment Plants specializes in aerobic treatment plants and advanced membrane-based systems.

Key Offerings:

- Modular sewage treatment plants with plug-and-play installation

- RO-integrated STPs for water reuse applications

- Zero Liquid Discharge (ZLD) systems for industries

- Automated control systems for minimal manual intervention

3: Urban STP Plant

Known for its pre-fabricated sewage treatment plants, Urban STP Plant provides cost-effective and space-saving solutions.

Key Offerings:

- Containerized STPs for easy relocation

- Hybrid treatment systems combining MBR and activated sludge processes

- Low-maintenance designs with simple controls

4: Water Treatment Plant

Specializing in underground sewage water treatment plants, this company focuses on eco-friendly and odor-free solutions.

Key Offerings:

- Odorless underground STPs for residential societies

- Solar-powered sewage treatment systems

- Compact designs with minimal civil work required

5: Commercial RO Plant

A large-scale water treatment plant manufacturer, Commercial RO Plant handles mega projects for municipalities and industries.

Key Offerings:

- Large-capacity STPs (1 MLD to 100+ MLD)

- Turnkey project execution from design to commissioning

- Advanced tertiary treatment for water reuse

Key Features of Leading STP Manufacturers in Noida

1: Advanced Technologies Used:

- MBBR (Moving Bed Biofilm Reactor)—High efficiency, low space requirement

- MBR (Membrane Bioreactor)—filtration, reusable water quality

- SBR (Sequential Batch Reactor)—Ideal for intermittent flow

- Activated Sludge Process (ASP) — Traditional yet effective for large-scale treatment

2: Customized Solutions:

- Designs tailored to sewage quality requirements (BOD, COD, TSS removal)

- Scalable systems for future expansion

3: Compliance with Regulatory Standards:

- Meets CPCB and State Pollution Control Board norms

- Sewage discharge standards as per environmental laws

4: After-Sales Support:

- Installation, maintenance, and AMC (Annual Maintenance Contracts)

- Remote monitoring & automation options

Price Range and Operational Efficiency

The price range for sewage treatment plants varies based on capacity, technology, and customization:

| Plant Type | Capacity Range | Approx. Price Range (INR) |

| Compact STP | 5 KLD – 50 KLD | ₹5 Lakhs – ₹35 Lakhs |

| Modular STP | 50 KLD – 500 KLD | ₹35 Lakhs – ₹2.5 Crore |

| Underground STP | 10 KLD – 100 KLD | ₹10 Lakhs – ₹1 Crore |

| Industrial ETP | 100 KLD – 1 MLD | ₹50 Lakhs – ₹5 Crore |

Comparison Between Top STP Manufacturers in Noida

| Manufacturer | Technology Used | Capacity Range (KLD) | Price Range (₹) | Warranty | After-Sales Service |

| Netsol Water | MBBR/MBR | 1 – 50 | 3L – 35L | 1 year | 5 Years Support |

| Sewage Treatment Plants | SBR | 1 – 20 | 4.5L – 30L | 1 year | 24/7 support |

| Urban STP Plant | MBR | 2 – 100 | 6L – 70L | 1 year | On-site training |

| Water Treatment Plants | MBBR/MBR | 1 – 100 | 8L – 90L | 1 year | 24/7 Support |

Key:

- KLD= Kilo Liters per Day

- MBBR= Moving Bed Biofilm Reactor

- SBR= Sequential Batch Reactor

- MBR= Membrane Bioreactor

Factors Affecting Cost:

- Technology used (MBBR, MBR, SBR, etc.)

- Material (FRP, RCC, or stainless steel)

- Automation level (manual vs. PLC-controlled)

- Additional features (odor control, sludge dewatering)

Benefits of Modern Sewage Treatment Plants

- Energy-efficient operations (30-50% lower power consumption)

- Low maintenance with simple controls

- Scalable modular systems for future expansion

- Compliance with CPCB & NGT norms

Conclusion

Noida, Uttar Pradesh, is a key hub for sewage treatment plant manufacturers, providing advanced solutions like compact sewage treatment plants, modular sewage treatment systems, and underground sewage water treatment plants. Companies like Netsol Water lead the market with innovative, cost-effective, and eco-friendly water treatment technologies.

For businesses and industries looking for reliable water treatment plants, Noida-based manufacturers offer a complete range of high-quality products with efficient delivery time and excellent after-sales support.

Investing in a modern sewage treatment plant ensures sustainable wastewater management while reducing long-term operational costs. Choose a trusted sewage treatment plant manufacturer in Noida for durable and efficient solutions.

FAQ Section

1. What’s the cost of a 100 KLD sewage treatment plant in Noida?

Prices range ₹20 – ₹55L depending on technology (MBBR/SBR/MBR) and brand. Contact us for a custom quote.

2. How to choose the best STP manufacturer in Noida?

-

Check certifications (CPCB, ISO).

-

Compare warranty and maintenance terms.

-

Ask for client references (e.g., hotels/apartments they’ve served).

3. What maintenance does an STP require?

-

Monthly sludge removal.

-

Quarterly membrane cleaning (for MBR).

-

Annual motor servicing.

4. Which STP technology is best for hotels in Noida?

MBBR (for compact spaces) or MBR (for high-quality effluent). Avoid SBR if space is limited.

5. Do you provide installation support in Noida?

Yes! We handle site inspection, installation, and staff training for all Noida clients.

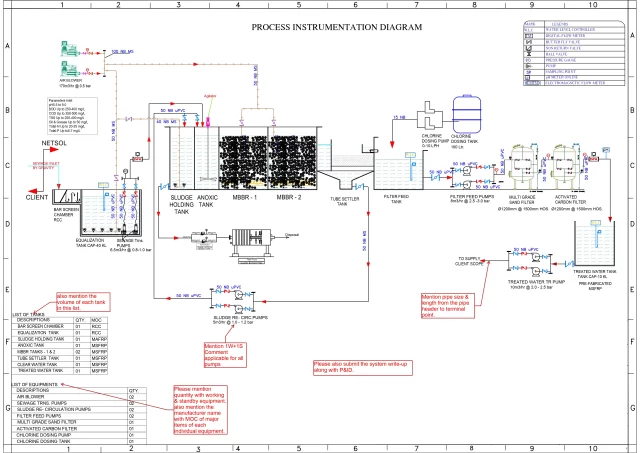

P&ID 100 KLD STP Plant MBBR Technology