How to Increase Water Pressure in RO System

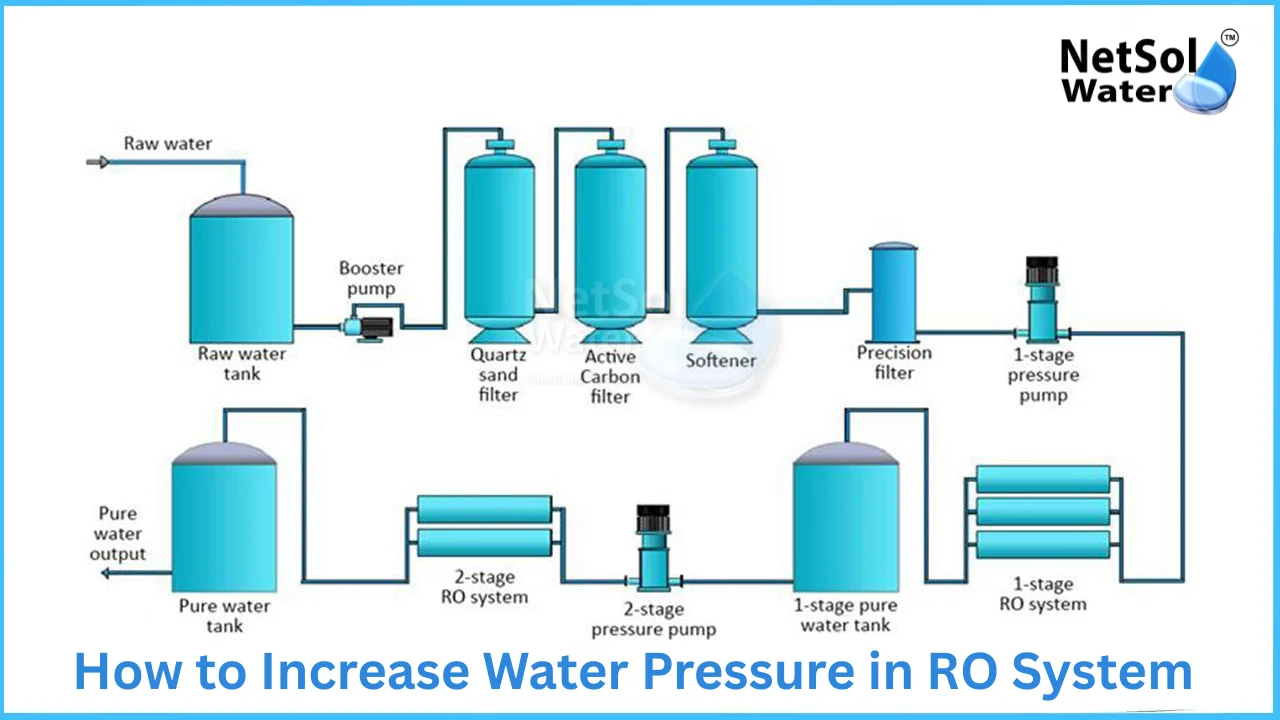

Water pressure matters when you use an RO plant. Low pressure can slow down the flow and reduce the output of clean water. People and industries in Noida and nearby areas look for reliable RO solutions. Netsol Water is the leading Commercial RO Plant Manufacturer and it serves many clients in India. We will explore how to increase water pressure in RO plant.

Check and Upgrade the Feed Water Supply

Good feed water pressure forms the base for any RO system. If the incoming pressure stays low the system cannot push water through the membrane. Let us have a look on some steps that will improve the feed supply and raise the pressure to the RO plant.

Inspect inlet pipe and valve

Start by checking the inlet pipe and the inlet valve. Look for any narrow or long pipes that reduce flow. Replace old pipes that have scale or deposits built inside. Open the inlet valve fully to allow full feed pressure to reach the RO plant. Confirm there are no hidden bends that choke the flow. A straight and wider pipe helps the water move faster. Check the municipal or bore well pressure at the point where the pipe joins the RO. If the source pressure reads low then the system will not perform well.

Install a booster pump

When the feed source cannot provide enough pressure a booster pump will help. Choose a pump rated for RO use and with stable output. Install the pump before the prefilters so that all stages see higher pressure. A pump will cut the filling time and increase the daily output. Make sure the pump has a pressure switch and an automatic shut off to protect the membrane. A good pump reduces pressure loss and keeps the plant steady during peak use. A qualified technician should fit and test the pump to match the RO flow rate.

Maintain RO Filters and Membranes

Clean filters and a healthy membrane keep the pressure stable inside the RO plant. Clogged prefilters raise the pressure drop and reduce flow. Let us have a look on some maintenance steps that will restore and keep proper pressure in the RO plant.

Clean and replace prefilters

Prefilters protect the membrane from sand, silt and chlorine. When these filters clog the pump must work harder and the pressure at the membrane drops. Check the sediment and carbon filters on a set schedule. Replace them when they show signs of dirt or when the flow slows. Use quality cartridges that match the system design. A clean prefilter set will let the feed pressure reach the membrane at the expected level. Regular replacement keeps the whole system balanced and reduces stress on the pump.

Service the membrane and test flow rates

The membrane is the heart of the RO plant. A fouled membrane will cut the flow and raise the pressure loss across the unit. Perform routine cleaning of the membrane following manufacturer guidance. Test the permeate and reject flows to confirm the membrane still performs well. If cleaning does not recover the output then replace the membrane. A new membrane will restore the design flow and lower the pressure load on the pump. Keep records of flow rates and cleaning cycles to plan timely service.

Adjust System Settings

Control settings and small accessories affect the pressure at the tap and the system output. Proper settings and the right accessories will keep the pressure steady under different demand levels. Let us have a look on some adjustments and upgrades that support higher pressure in the working system.

Set pressure switches and tank pressure

The pressure switch controls pump start and stop points. Set the switch thresholds to match the pump and the RO specifications. If the cut in point is too low the pump may not reach the needed pressure. The pressure tank also plays a role. Check the tank precharge and adjust it slightly below the cut in pressure. A correct tank pressure reduces pump cycling and keeps the outlet steady. Test the system under normal draw conditions and fine tune the switch settings to keep a steady flow without overworking the pump.

Add gauges and upgrade the storage tank

A pressure gauge at key points helps to spot pressure losses quickly. Fit gauges at the pump outlet and at the RO outlet. Use the readings to identify where the pressure drops. If the storage tank is small or aged replace it with a larger or better lined tank. A larger tank reduces the number of pump starts and helps maintain steady pressure at taps. Also consider a booster stage after the storage tank if you need higher delivery pressure for specific equipment. These upgrades work together to give a stable supply and ease the load on the core RO components.

Read some interesting information for Industrial RO Plant Manufacturer

Conclusion

Good pressure makes an RO plant work well and last longer. Check the feed source the filters the membrane and the controls to find and fix the weak point. Netsol Water is the leading Commercial RO Plant Manufacturer and we help clients boost pressure with the right pump the right settings and the right maintenance plan. If you need advice or a site visit contact Netsol Water for a consultation. Our team will evaluate your system and suggest a clear plan to increase your RO water pressure and improve daily output.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com