Emerging Trends: Nanotechnology in Wastewater Filtration

Wastewater Management faces rising demands as cities and industries seek cleaner water and lower costs. New limits on discharges and new goals for reuse require plants to work harder and to use smarter tools. Nanotechnology offers small scale solutions that change how filters work and how managers detect and remove pollutants. These advances help plants treat water more efficiently and they can lower energy use and reduce waste. The changes also open paths to capture contaminants that older systems often miss.

Nanomaterials for Filtration

Nanomaterials can change how filters work. Let us have a look on some main materials and how they perform.

Carbon Nanotubes

Carbon offer strong flow and fine capture of small particles. Plants use them to remove organic matter and certain heavy metals. The tubes form dense networks that trap pollutants while letting water pass. Operators report higher throughput with lower pressure loss. The tubes also resist wear and tear. This means fewer replacements and lower downtime. In field tests filters with these tubes show longer life than many older media. The tubes also help when plants face sudden load spikes. The system keeps working while the filter clears faster during cleaning cycles. Careful design keeps production and disposal safe. Plants must follow handling rules to protect workers and the environment.

Graphene Based Filters

Graphene based filters use thin sheets of carbon that act like sieves at the nano scale. They remove tiny particles and some dissolved organics with high efficiency. The sheets also add strength and reduce fouling on the surface. Plants see more stable flows over long runs. Maintenance staff clean the surfaces more easily. Builders can coat existing membranes with graphene layers to boost performance. The coating improves rejection rates for small molecules that older membranes miss. Researchers pair graphene with other media to target specific pollutants. For example pairing with activated carbon can catch both small organics and dyes. The result fits many textile and dyeing units that need higher quality reuse water. Wider use needs cost cuts and clear safety plans.

Nanocoatings and Surface Functionalization

Coatings change how surfaces meet water and pollutants. Let us have a look on some key coating approaches and their effects.

Antifouling Coatings

Antifouling coatings keep filter surfaces clean for longer. The coatings reduce the build up of bio film and trapped solids. Plants that add these coatings need fewer cleanings. They also use less chemical cleaning agents. The reduced cleaning saves money and lowers the risk of membrane damage. Operators can plan longer service intervals and steadier flow. Antifouling layers often change the surface energy so particles fail to stick. That change creates smoother operation and simpler maintenance routines. This approach fits plants with high organic loads. Textile mills and food units benefit because their effluents cause fast fouling in old systems. Trials show cleaner runs and more predictable output when the coating holds up under real load cycles.

Reactive Surface Coatings

Reactive coatings can hold catalysts that turn hard to treat molecules into safer ones. This step reduces load before the next treatment stage. Plants place these coatings on pipes and on membrane faces. The result cuts stress on downstream units. Reactive coatings also help remove some micro pollutants that passive filters miss. Developers tune the coating to target types of waste found at a site. This helps match the solution to local needs. Safety checks ensure that coating fragments do not enter the treated water. Operators run regular tests to confirm stability and to adjust replacement schedules.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Delhi

Nanotechnology for Detection and Pathogen Removal

We will look at how nanotechnology helps detect and remove pathogens. Let us have a look on some sensor and disinfection options that teams can use.

Nanosensors for Real Time Monitoring

Nanosensors detect small changes fast. Plants use them to watch turbidity and trace chemicals. The sensors send near real time alerts when a pollutant spike arrives. Managers then adjust flows or add steps before the problem spreads. This quick response saves water and prevents permit violations. Nanosensors also aid process control. They feed data to automatic valves and to dosing systems. The result is steadier output with less manual intervention. Sensors tend to cost less as production scales. They also link well to cloud tools that store and show trends. Operators use this trend data to plan maintenance and to spot slow changes that need repair.

Nanoenabled Disinfection

Nanoenabled disinfection uses small particles to reduce pathogens. Some particles kill bacteria. Others work as catalysts under light to destroy microbes. Plants add these particles in fixed beds or as coatings on surfaces. The approach can lower reliance on chemical disinfectants. That change can cut by products that cause odor or that harm downstream ecosystems. Trials show strong pathogen reduction with careful control of contact time. Plant staff must follow rules to keep particles from leaving the system.

Conclusion

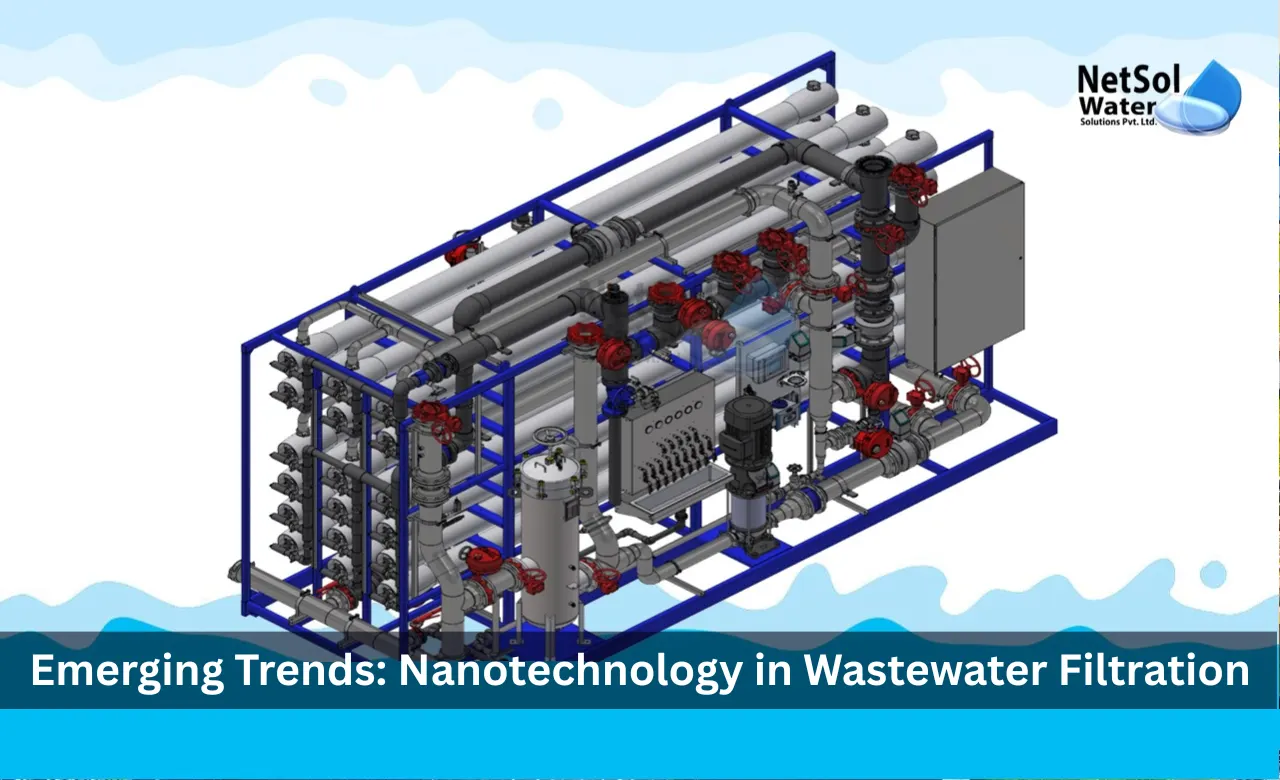

Wastewater Management must move with new tools that offer better results and lower life cycle cost. Nanotechnology brings filters coatings sensors and disinfection tools that can change how plants work. These trends help plants reach higher reuse targets and reduce waste. Netsol Water is the leading partner for firms that want to test these methods in Noida and nearby areas. Netsol Water, a trusted Commercial RO Plant Manufacturer, is the leading partner for firms that want to test these methods in Noida and nearby areas. Contact us to learn how these technologies can fit your site and to request a consultation on pilot trials. Reach out for a discussion and for practical next steps.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com