Water Treatment Equipment Manufacturers in India

India is famous for its varied climates and its large industrial sectors. These industrial sectors create demand for clean water solutions for homes, farms and factories. Water treatment plants help communities and businesses use water safely and save water for future use. A Water Treatment Plant Manufacturer plays a key role in designing building and supplying plants that treat water for drinking for industrial use and for wastewater reuse. Netsol Water is the leading Water Treatment Plant Manufacturer and it serves customers across India with plants that match local needs.

Manufacturing Capabilities and Technologies

Good manufacturing lets companies build plants that work for specific water sources and for specific output needs. Let us have a look on some manufacturing capabilities and technologies.

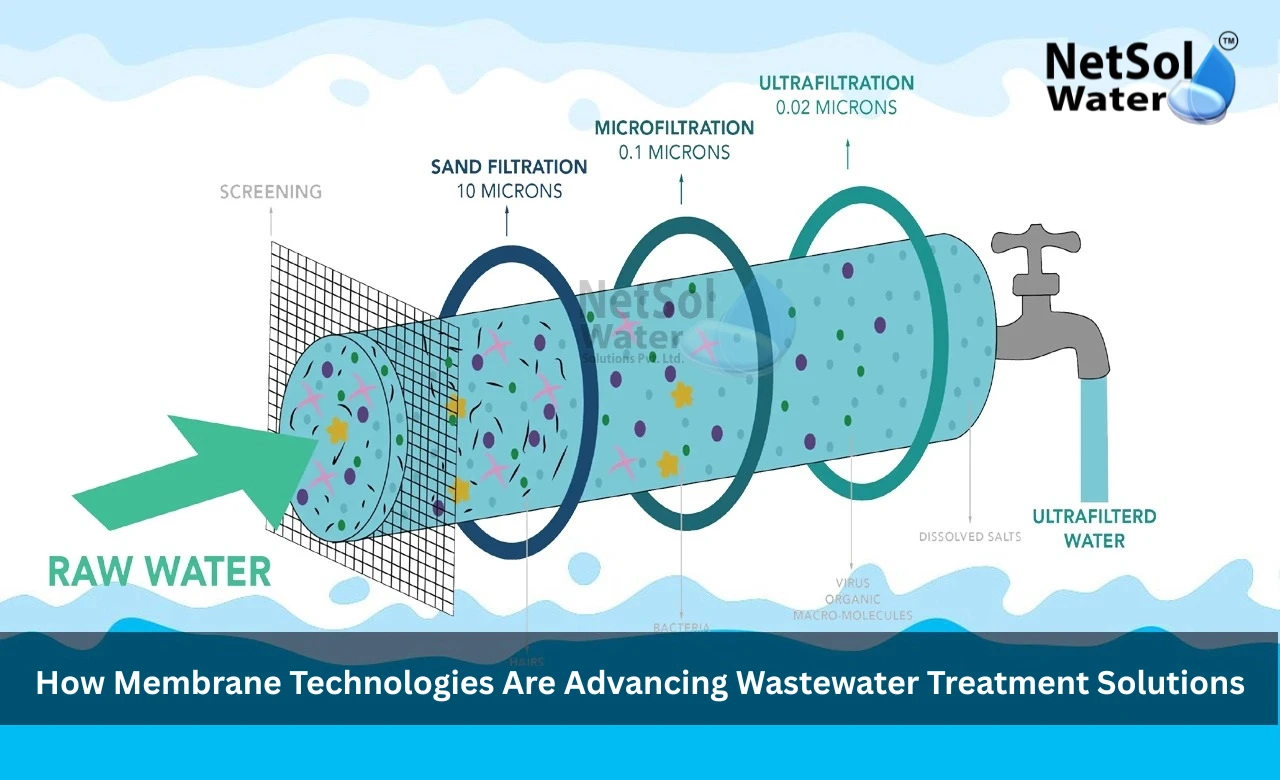

Membrane Filtration Systems

Membrane filtration covers processes like microfiltration, ultrafiltration, nanofiltration and reverse osmosis. These systems remove particles and dissolved salts from water. Indian manufacturers design membrane trains that match the feed water quality and the required product water standard. A manufacturer selects the correct membrane type and sets the flow and pressure to reach the desired output. The assembly includes pressure vessels membrane modules pumps and control panels. Local makers can source many components from Indian suppliers and they can also integrate imported membranes when needed. The result is a compact plant that uses less space and that can run with lower operator attention than older systems. Engineers test the membranes and tune the plant for efficiency. They provide options for cleaning cycles and for monitoring to keep performance steady over time.

Chemical Treatment Units

Chemical treatment remains important for removing dissolved substances controlling scale and ensuring safe disinfection. Chemical systems include dosing pumps mixing tanks and contact chambers. Manufacturers build these units to work with coagulants flocculants pH adjusters and disinfectants. They design the feed path and the control logic to create good mixing and to avoid overdose. Indian makers also add safety features to store chemicals and to prevent spills. They offer training to plant operators so that dosing stays accurate and safe. Chemical units can work with membrane filters clarifiers or sand filters as part of a combined plant. The manufacturer sets the control system to coordinate dosing with other treatment steps. This approach keeps water quality stable and reduces the need for manual corrections.

Quality Standards and After Sales Support

A manufacturer must make plants that meet regulations and that perform reliably for years. Let us have a look on some quality checks and on the services that keep plants running.

Quality Certification and Testing

Certification proves that a plant meets required norms for safety and performance. Manufacturers test instruments pumps and tanks during production. They run factory acceptance tests and they document the results for the client. This process checks flow rates pressure drops and water quality after each treatment step. Many producers follow national and international standards to show compliance. They prepare test reports and they offer third party testing when the buyer asks for it. Good documentation helps clients get permits and it supports project handover. The manufacturer also uses quality control on components and keeps records that trace each part. This traceability reduces the risk of failure and speeds up problem solving when issues occur after installation.

Maintenance and Service

After sales service keeps a plant productive and it protects the capital investment. Manufacturers offer service contracts spare part supply and training for in house technicians. A clear maintenance plan lists routine checks service intervals and part replacements. Manufacturers often provide remote monitoring and support to spot issues early. They send technicians to site for repairs and for seasonal tuning. They stock common spare parts to reduce downtime. This service model helps plants stay within operational budgets and it improves plant life. Clients gain confidence when a manufacturer commits to response times and to long term parts availability.

Read some interesting information for Sewage Treatment Plant Manufacturer in Noida

Conclusion

A strong Water Treatment Plant Manufacturer helps communities and businesses meet water needs with reliable plants, clear documentation and support. Netsol Water is the leading Water Treatment Plant Manufacturer and it can plan, build and service plants for varied uses. If you want more information or if you would like a consultation please get in touch with a specialist who can review your water source your treatment needs and your budget. Request a consultation today.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com