Harnessing Biogas from Wastewater: Revenue Streams for Treatment Plants

India is known for its fast growing cities, rich culture and strong industrial base. Many cities are famous for rivers that support life farming and industry. With this growth comes a large volume of wastewater that needs proper treatment. This creates a challenge but it also opens a strong opportunity. When a Wastewater Treatment Plant treats sewage it does more than clean water. It also produces organic waste that holds hidden energy. This energy can turn into biogas which helps plants earn extra income and reduce operating cost.

Harnessing biogas from wastewater changes the role of treatment plants. Instead of working only as a cost center they become resource recovery units. This idea gains importance today because energy prices rise and sustainability goals become strict. Many plant owners now look for ways to improve financial returns while meeting environmental rules. Biogas recovery supports both needs in a simple way.

Netsol Water is the leading company and Sewage Treatment Plant Manufacturer in this field. The company designs solutions that help treatment plants convert waste into value. Through smart planning and simple technology even medium sized plants can benefit from biogas. Understanding how this process works and how it creates revenue helps decision makers plan better plants for the future.

Biogas Generation in Wastewater Treatment

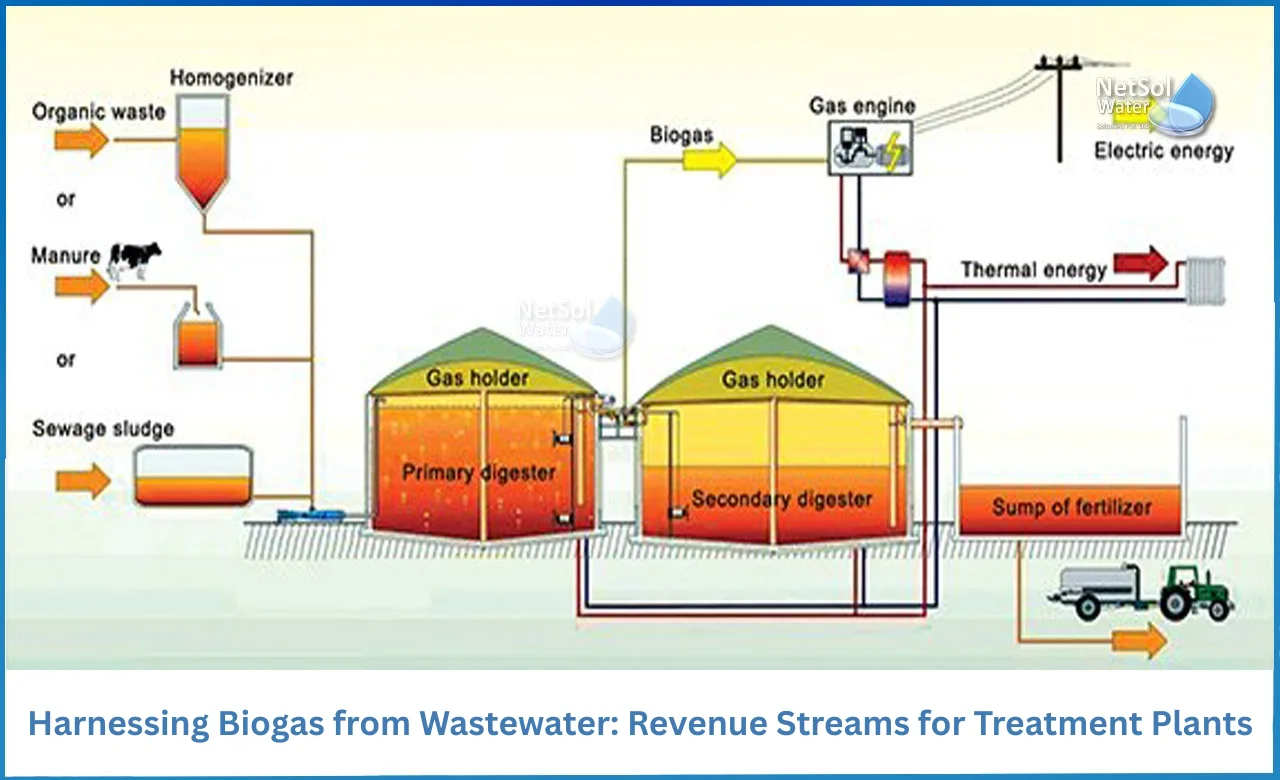

Biogas generation plays a central role in making a treatment plant profitable. It starts with the sludge that forms during wastewater treatment. This sludge contains organic matter that bacteria can break down. When this breakdown happens in the absence of oxygen it produces biogas mainly made of methane and carbon dioxide.

Let us have a look on some key aspects of this process that make it useful for revenue creation.

Anaerobic Digestion Process

Anaerobic digestion forms the heart of biogas production. In this process sludge enters a closed tank called a digester. Inside the tank bacteria work on the organic content and release gas. The process needs controlled temperature and steady feeding. When managed well it runs smoothly for years.

This digestion reduces sludge volume which lowers disposal cost. At the same time it produces biogas that plants can capture and store. This gas becomes a direct energy source for the facility. Operators use it for heating digesters or running engines. This dual benefit improves plant efficiency and financial performance.

Quality and Quantity of Biogas

The value of biogas depends on its quality and volume. Methane content decides how much energy the gas holds. Stable digestion ensures higher methane levels. Proper mixing and feeding improve gas output over time.

When plants monitor gas production regularly they can plan energy use better. Consistent quality allows connection with generators or boilers without risk. This stability makes biogas a reliable part of daily operations rather than a side product.

Revenue Streams from Biogas Utilization

Biogas creates several income options for treatment plants. Each option adds value in a different way. Together they change the economics of a Wastewater Treatment Plant and support long term sustainability.

Let us have a look on some major revenue streams that biogas offers.

On Site Power Generation

Using biogas to generate electricity is one of the most common approaches. Plants install gas engines or turbines that convert biogas into power. This power runs pumps blowers and lighting inside the facility.

By producing their own electricity plants reduce dependence on the grid. This saves money every month. In many cases excess power feeds into local grids where policy allows. This creates a direct income stream. Over time energy savings recover the investment cost and continue to deliver profit.

Heat Recovery and Process Use

Biogas engines also produce heat. Plants capture this heat and use it in digestion tanks or for drying sludge. This reduces the need for external fuel.

Using recovered heat improves overall energy efficiency. It lowers fuel bills and keeps the digestion process stable. Though this benefit may not appear as direct cash income it strongly reduces operating expenses which improves net revenue.

Sale of Upgraded Biogas

Some plants upgrade biogas to biomethane by removing impurities. This upgraded gas meets fuel standards. Plants can compress it and sell it for transport or industrial use.

This option suits large facilities with steady gas output. Selling biomethane opens a new market for treatment plants. It also supports clean energy goals at a regional level.

Environmental and Social Benefits Supporting Revenue

Revenue from biogas does not stand alone. Environmental and social benefits support financial gains indirectly. These benefits improve project approval and long term acceptance.

Let us have a look on how these factors strengthen plant economics.

Reduced Carbon Footprint

Biogas use reduces greenhouse gas emissions. Methane that would escape into the air gets captured and used. This lowers climate impact.

Many regions offer incentives for emission reduction. Plants may earn carbon credits or tax benefits. These incentives add to revenue while supporting national climate targets.

Improved Public Image and Compliance

Plants that recover energy from waste gain public trust. Communities see them as clean and responsible facilities. This positive image helps during expansion or approval processes.

Strong compliance with environmental rules avoids penalties and delays. Smooth operations save money and time. Over years these savings translate into significant financial value.

Role of Netsol Water in Biogas Based Solutions

Implementing biogas systems requires experience and careful design. Netsol Water is the leading provider and Sewage Treatment Plant Manufacturer of such solutions in India. The company understands local conditions and plant needs.

Netsol Water plants that work reliably. Their approach focuses on simplicity and long term performance. By integrating biogas recovery into the Wastewater Treatment Plant design they help clients achieve faster returns.

The company also supports operation and maintenance. This ensures stable gas production and steady revenue. With proper guidance plants avoid common issues and maximize benefits from wastewater resources.

Read some interesting information for the Commercial RO Plant Manufacturer in Noida

Conclusion

Harnessing biogas transforms how a Wastewater Treatment Plant functions in today’s world. It turns waste into energy and energy into income while protecting the environment. Plants that adopt this approach reduce costs generate power and build a sustainable future. For operators and planners this path offers both financial sense and social value. Reach out to experts to explore how biogas recovery can fit into your project. Connect with Netsol Water to request a consultation and learn how your wastewater can become a steady source of revenue.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com