What are the principles of Filtration in Water Treatment?

Filtration forms a core step in any Water Treatment Plant. Netsol Water is a leading manufacturer of water treatment plants in India, known for its reliable designs and transparent methods. Filtration protects pipes, pumps, and public health by removing particles and impurities that would damage equipment or pose a risk to life.

Mechanical Straining

Mechanical straining forms the first step in most Water Treatment Plant setups. It works by placing a physical barrier in the flow path so that large particles cannot pass through. Let us have a look on some key types of mechanical strainers and see how they work.

Fine Mesh Screens

Fine mesh screens use woven material with uniform gaps to trap particles that exceed a set size. These screens sit inside a frame or housing that water flows through. As water enters the device the mesh holds back debris such as leaves sand and floatable solids. Operators choose screen openings based on the size of particles that should be removed. They inspect and clean the mesh at regular intervals to avoid clogging. This process ensures steady flow and long life for pumps and other devices.

Cloth Filters

Cloth filters use layers of synthetic or natural fabric folded or pleated to create a large surface area. Water passes through the cloth layers and solids cling to fiber surfaces. The cloth can remove particles much smaller than what mesh screens catch. Workers remove trapped solids by backwashing or by replacing cloth elements. Cloth filters prove easy to maintain and scale up by adding more layers or larger frames. These filters act as a bridge between coarse screens and fine depth filtration. They provide a reliable step that keeps media in later filters from becoming clogged too quickly.

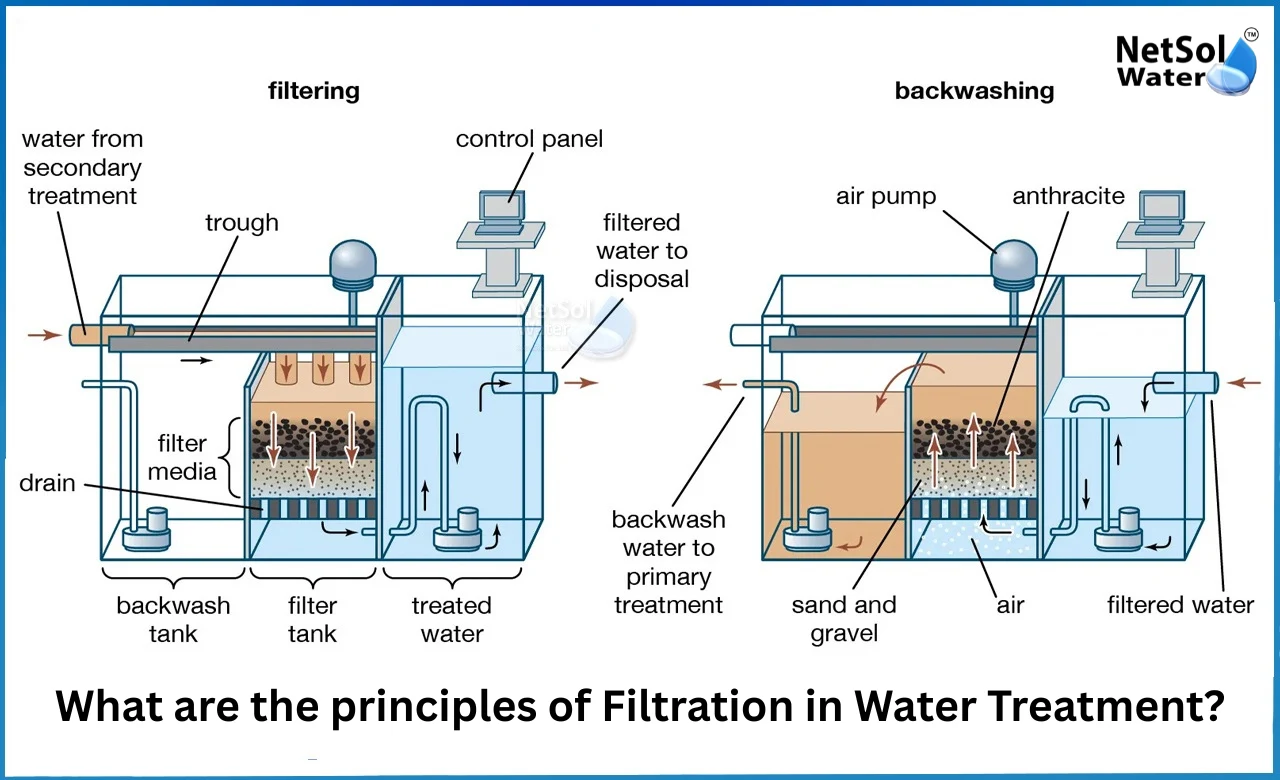

Depth Filtration

Depth filtration digs deeper into particle removal. It sends water through a porous media bed where solids lodge within the media instead of only on the surface. This way the filter holds more contaminants before requiring cleaning or replacement. Let us have a look on some common media beds and their detailed roles.

Single Media Sand Filters

Sand filters use layers of graded sand with coarser grains at the top and finer grains below. Water flows downward and larger particles settle in the top layer while finer matter travels deeper until it reaches a layer that matches its size. This setup allows the bed to trap a wide range of solids in one vessel. Operators backwash the filter by reversing flow and flushing trapped debris out the top. Sand filters remove suspended solids and reduce turbidity in a reliable way. They work well for municipal water treatment and many industrial uses.

Dual Media and Multimedia Filters

Dual media filters layer sand over anthracite coal. Multimedia filters add garnet or other dense media beneath sand and anthracite. The different densities and sizes allow particles of various dimensions to embed across multiple layers. This multi level capture extends the run time before backwashing and improves water clarity further. Operators adjust flow rates and backwash cycles to suit the feed water quality. Multimedia beds stand out for their high capacity and fine removal performance. A Water Treatment Plant that uses these beds can operate longer without maintenance and yield water that meets strict clarity standards.

Adsorption Filtration

Adsorption filtration tackles dissolved and colloidal contaminants that pass through mechanical and depth filters. It uses the tendency of particles or molecules to cling to solid surfaces. This principle excels at removing chemicals that affect taste odor and health from water. Let us have a look on some common adsorbents and their roles.

Activated Carbon Beds

Activated carbon comes from sources such as coconut shell or coal. Processors heat and treat the carbon to create a highly porous structure. Water flows through a bed of carbon granules or pellets and dissolved organics and chlorine compounds stick to the surfaces. This step removes bad tastes odors and toxic chemicals that other filters leave behind. Operators backwash carbon beds to clear fines and then replace the media when adsorption sites fill. Activated carbon works at low pressure loss and handles a wide range of chemical contaminants in a Water Treatment Plant.

Ion Exchange Resins

Ion exchange resins use charged polymer beads to swap undesirable ions with harmless ions in the water. For instance a cation resin may release sodium ions in exchange for hardness ions such as calcium and magnesium. As water flows through the resin column the targeted ions adhere to the beads. When the resin nears full capacity operators regenerate it by flushing with a concentrated salt solution. This process restores the bead charge and makes the resin ready for more cycles. Ion exchange excels at softening water and removing heavy metals or nitrates that pose health concerns.

Conclusion

By using mechanical straining depth filtration and adsorption steps a full scale system can remove particles chemicals and microbes from raw water. Netsol Water is the leading Water Treatment Plant Manufacturer that applies these principles with precision and care. If you seek a reliable water solution or want to discuss a custom project please get in touch for more information or request a consultation.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com