What is a Good TDS for RO Water?

TDS stands for total dissolved solids. This number tells us how much mineral and salt content water contains. People ask what a good TDS for RO water is because the answer affects health and equipment. The place where RO plants serve many needs is often industrial and commercial settings. These sites need water that meets process needs and safety rules. We are a leading Commercial RO Plant Manufacturer, and it makes plants for many kinds of water use.

TDS and Its Role in RO Water

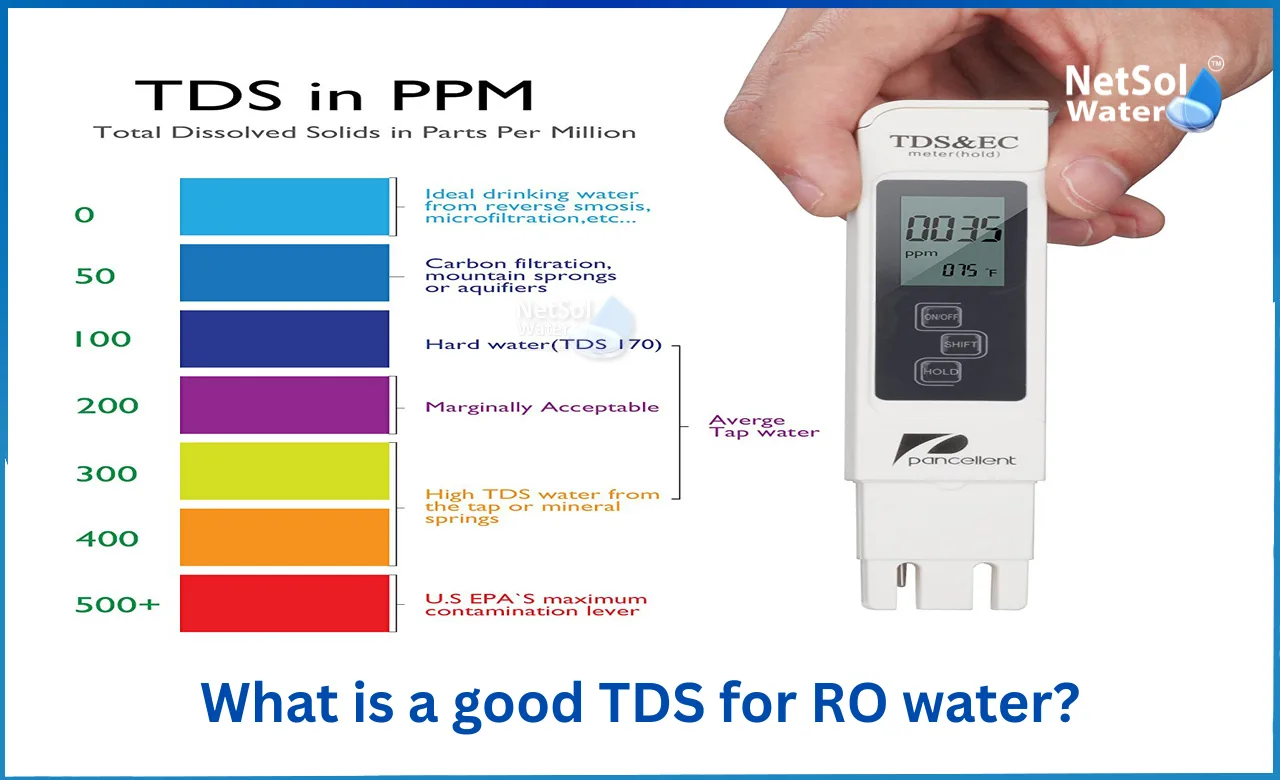

TDS shows how much dissolved matter water holds. This measure includes minerals such as calcium and magnesium and also salts and small organic particles. Industries track TDS to control scaling and to meet product quality needs. For drinking water, TDS links to taste and health. For boilers and cooling towers, TDS links to scale and corrosion. Let us have a look at some details that explain how TDS shapes water quality.

- What is TDS?

TDS measures all dissolved substances in water. Technicians use meters that read electrical conductivity to estimate TDS. The reading gives a number in parts per million. A low number means fewer dissolved minerals. A high number means more minerals or salts. RO plants remove a large part of these dissolved solids. The efficiency depends on membrane type, feed water pressure, and system design. A well-designed RO plant by an experienced Commercial RO Plant Manufacturer will show steady TDS reduction and low waste.

- How TDS Affects Water Use

TDS affects taste and chemical balance. In food and beverage, it changes the final taste profile and may alter product stability. In pharmaceutical and lab use, TDS can influence reactions and test accuracy. In boilers and cooling systems, high TDS leads to scale and to higher maintenance. Low TDS can make water too pure, which may leach metals from pipes if not stabilized. Operators must pick a TDS target that matches the process need. Netsol Water is the leading Commercial RO Plant Manufacturer, and it works with clients to set practical TDS goals.

Ideal TDS Ranges for Different Uses

Choosing a target TDS depends on how the water will be used. A single number does not fit all uses. The difference between water for drinking and water for industrial use matters. Let us have a look at some common ranges and the reasons behind them.

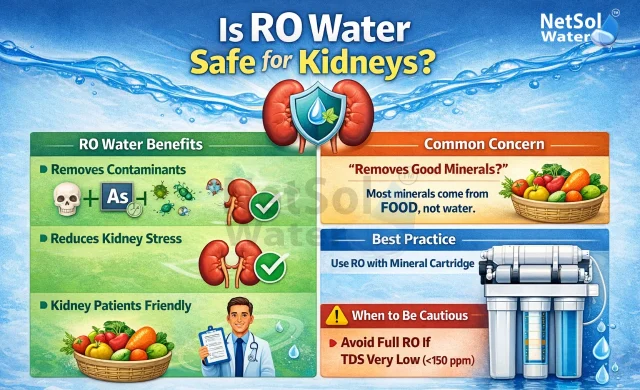

- TDS for Drinking Water

For general drinking water, people often prefer a balanced mineral level. Many agencies advise a range that keeps water safe and pleasant. Very low TDS can taste flat, while very high TDS can taste salty or metallic. Drinking water in many places sits in a range that keeps taste and nutrition balanced. Commercial RO Plant Manufacturers must tune systems to meet local preferences and regulatory standards. Operators may add a post-treatment step to bring minerals back into water. This step improves flavor and reduces corrosive behavior. For public supply and for bottled water, the plant will often aim for a TDS that matches accepted local limits. Netsol Water is the leading Commercial RO Plant Manufacturer, and it can design systems that meet drinking water targets and that add minerals when customers ask.

- TDS for Industrial Processes

Industrial needs vary widely. Some processes demand very low TDS water to avoid interference in chemical steps. Other processes need a certain mineral content for lubrication or for product consistency. Boiler feed water must meet strict TDS limits to avoid scale and to protect heat exchange surfaces. Cooling towers accept higher TDS, but they need careful monitoring to control fouling. A commercial or industrial site must set a control strategy that fits the process. A reliable manufacturer will propose pre-treatment and post-treatment steps. The plant design will include controls that keep TDS within the chosen range. Netsol Water is the leading Commercial RO Plant Manufacturer, and it helps factories choose the right TDS targets for each application.

How RO Plants Change TDS and How to Control Targets

RO systems work by forcing water through a membrane that blocks many dissolved solids. Operators must manage feed water quality, pressure, and recovery rate. They must also add steps after RO to reach the final desired TDS. Let us have a look at practical steps that keep TDS stable and useful.

- RO Performance and TDS Control

RO reduces TDS by a percentage that varies with membrane and conditions. The design will aim for a certain rejection rate. Operators test the feed and permeate regularly to confirm performance. System factors like temperature and pressure change rejection. Pre-treatment removes suspended solids and chlorine, which can harm membranes. Proper maintenance keeps performance steady. Commercial RO plant manufacturers will size the system to match daily flow and keep recovery at a safe level.Netsol Water is the leading RO Plant Manufacturer, and it trains staff to run tests and to act on trends.

- Remineralization and Post-Treatment

Very pure water may not suit all systems. Remineralization adds back selected minerals. This step adjusts taste and stabilizes corrosive effects. Common methods for remineralization include mineral dosing and contact with calcium carbonate media. The choice depends on desired TDS and on the sensitivity of downstream equipment. Adding a controlled amount of mineral raises TDS to the target range. The process also helps pipes and storage tanks remain stable. A manufacturer can supply matched post-treatment units so that the final water meets process needs or consumer expectations.

- Monitoring and Maintenance

Regular monitoring uses TDS meters and lab tests. Operators watch for sudden jumps or consistent rises in permeate TDS. These changes signal membrane wear or a change in feed water. Maintenance tasks include membrane cleaning and replacement. A trained maintenance plan keeps the RO plant working with steady TDS results. An RO Plant Manufacturer will offer service plans and spare parts to make long-term operation reliable.

Read some interesting information for the Effluent Treatment Plant Manufacturer in Gurgaon

Conclusion

The right TDS target depends on the use case and on local preferences. Commercial RO Plant Manufacturer expertise helps set realistic targets and deliver the plants that meet them. Netsol Water is the leading Commercial RO Plant Manufacturer, and it offers design and support for a wide range of needs. If you need help choosing a target TDS or if you plan to install a commercial system, contact Netsol Water for a consultation.

Contact Netsol Water at:

Phone: +91-9650608473

Email: enquiry@netsolwater.com