Netsol Water – Gurgaon’s Water Purification Expert

Gurgaon stands as a centre of modern business and fast growth. Netsol Water acts as Gurgaon’s water treatment expert. We bring clear, safe water where you need it most. As the leading Commercial RO Plant Manufacturer in Gurgaon, we design plants that meet diverse needs. Our focus on reliability and user ease makes us the partner businesses trust.

Why Choose Netsol Water

Every business requires a partner it can count on for pure water and prompt service. At Netsol Water we understand those needs. We combine deep local insight with proven engineering to deliver lasting results. Let us have a look on some key reasons that set Netsol Water apart.

Local Expertise and Rapid Response

Our team works right here in Gurgaon. We know local water profiles and supply challenges. That insight lets us design plants that tackle real issues from the first day. When you call for help our technicians arrive fast. They carry common spare parts and tools so they fix faults on the spot. This reduces downtime and keeps your operations running.

Customized Solutions for Every Industry

We treat each project as unique. We ask about your water source, daily volume needs and quality goals. Then we propose a plant sized to fit that exact profile. We adapt our modular RO units to fit tight spaces or support future expansion.

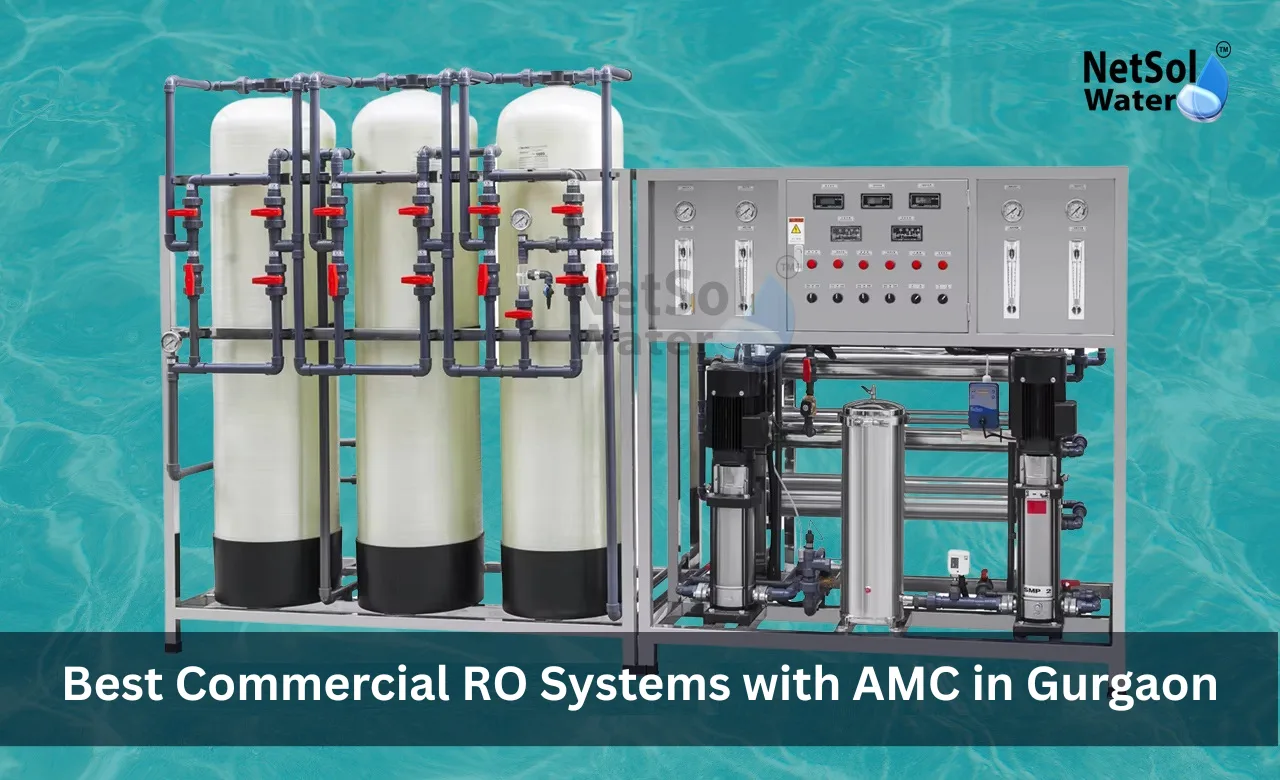

Features of our Commercial RO Plants

A top‑grade RO plant must blend efficiency, resilience and ease of use. Let us have a look on some standout features we build into every plant.

High‑Efficiency Membrane Arrays

Our plants use advanced thin‑film composite membranes. They remove dissolved solids while delivering high flow rates. A smart manifold design ensures balanced pressure across all membranes. That balance extends membrane life and reduces energy draw. You gain more treated water per kilowatt hour and you replace membranes less often.

Intelligent Control and Monitoring

We equip each plant with an intuitive digital panel. It tracks feed pressure, permeate TDS and pump status in real time. The system warns you of unusual trends long before they become faults. You can view logs on the screen or send them to your office network. This transparency lets your operators spot issues early and act with confidence.

Benefits of our Commercial RO Plants

Selecting the right Commercial RO Plant Manufacturer in Gurgaon brings benefits in water quality, cost, and peace of mind. Let us take a look at the advantages our clients enjoy.

Consistent Water Quality

Our plants deliver stable output free of salts, heavy metals and organic load. You get water that meets industrial benchmarks or food‑grade standards. This consistency protects your equipment from scale and corrosion. It also shields your processes from variable input. You avoid scrap batches, downtime and unexpected maintenance.

Lower Operating Costs

High recovery rates, efficient pumps and smart controls cut your energy and chemical bills. You spend less on membrane replacements thanks to balanced flows and prefiltration. Our preventative‑maintenance plans reduce emergency call‑outs. Over the plant’s life you recover your investment through steady savings.

Our Process

A smooth path from inquiry to long‑term support defines our work. Let us have a look on the stages we follow with every client.

Consultation and Site Survey

We begin with a free consultation. Our engineer visits your site to test feed water and measure demands. We discuss your goals and budget. Then we propose a solution that fits both technical needs and financial plans. You see a clear cost‑benefit analysis before you invest.

Installation and Training

Once you approve the design we schedule installation at your convenience. Our certified team handles civil work, piping and electrical connections. After we complete commissioning we train your staff on daily checks and simple servicing. You gain confidence in operating and caring for the plant.

Ongoing Service and Upgrades

We offer personalized maintenance packages. They include scheduled visits, filter changes and membrane inspections. We monitor performance remotely when you opt in. If your water needs grow we upgrade your plant modularly. That flexibility protects your investment and scales with your business.

Conclusion

Netsol Water is a leading Commercial RO Plant Manufacturer in Gurgaon, which transforms your water challenge into a reliable resource. We stand ready with local expertise, advanced engineering and responsive service. Let us help you secure pure water for your operation. Contact Netsol Water today to discuss your needs or request a site survey. Our team will guide you every step toward better water and smoother workflows.

Phone: +91-965-060-8473

Email: enquiry@netsolwater.com