What is a Sewage Treatment Plant?

Sewage treatment plants are designed to treat and purify wastewater generated by households, industries, and commercial companies. The wastewater includes human and animal waste, food waste, cleaning products, and other contaminants.

The primary objective of a sewage treatment plant is to remove contaminants and pollutants from wastewater so that it can be safely disposed of or recycled for other uses. A sewage treatment plant typically consists of several stages, including primary, secondary, and tertiary treatment.

The primary treatment involves removing heavy solids and organic matter from the wastewater through a physical process such as sedimentation and screening. The secondary treatment is a biological process that includes removing the organic matter using microorganisms. The tertiary treatment, on the other hand, involves removing any remaining contaminants from the water through chemical or physical processes.

Sewage treatment plant manufacturers are essential to maintaining a clean and healthy environment. Untreated wastewater can have a significant impact on human health and the environment. It can lead to the spread of diseases, contaminate soil and water, and damage aquatic life.

Types of Sewage Treatment Plants

There are several types of sewage treatment plants, each with its own set of features and benefits. The most common types of sewage treatment plants include:

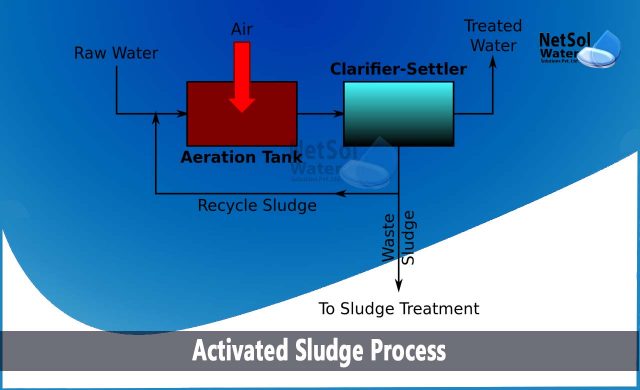

Activated Sludge Process (ASP)

The activated sludge process is the most commonly used sewage treatment plant. It involves introducing air into the wastewater to encourage the growth of microorganisms that break down organic matter. The process is effective in removing contaminants such as nitrogen and phosphorus.

The activated sludge process is widely used because it is effective in removing organic components and fertilizers from wastewater, and can be operated with a relatively small footprint. However, it can be energy-intensive due to the need for aeration and can also produce large amounts of excess sludge that require disposal or further treatment. As a result, modifications to the process, such as the use of advanced treatment technologies or the implementation of a sludge reduction program, may be necessary to optimize its performance and reduce its environmental impact.

Extended Aeration Process (EAP)

The extended aeration process is similar to the activated sludge process, but it involves a longer retention time. This allows the microorganisms to break down the organic matter more effectively, resulting in a higher quality of effluent.

The extended aeration process is known for its ability to produce high-quality effluent, even under variable or low wastewater flow conditions. It also typically requires less energy than other types of activated sludge processes, as the slower rate of microbial growth and longer aeration time results in less oxygen demand. However, the extended aeration process may require a larger footprint due to the larger aeration tank required and can produce more sludge than other processes, which may require additional handling and disposal.

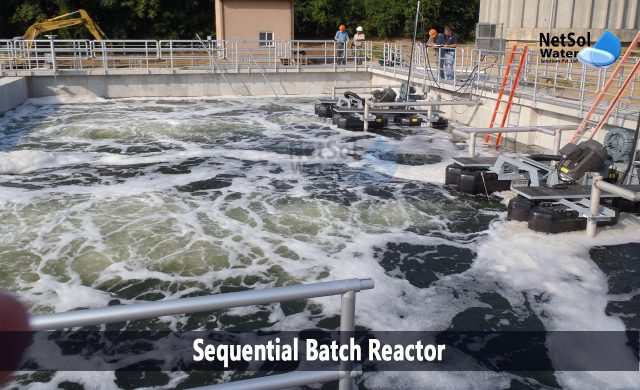

Sequential Batch Reactor (SBR)

The sequential batch reactor is a batch process that involves alternating between anoxic and aerobic conditions. This process allows for the removal of nitrogen and phosphorus from the wastewater.

SBRs can operate using either aerobic or anaerobic conditions, depending on the specific treatment needs. In the aerobic SBR, air is provided to the tank during the reaction phase to provide oxygen for the microorganisms. In the anaerobic SBR, the treatment occurs in the absence of oxygen, allowing anaerobic microorganisms to break down organic matter.

Membrane Bioreactor (MBR)

The membrane bioreactor combines biological treatment with membrane filtration to produce high-quality effluent. The process is efficient in removing solids and contaminants from the wastewater.

MBRs can use either submerged or external membrane filtration. Submerged MBRs place the membrane directly into the aeration tank, while in external MBRs, the membrane is placed in a separate tank and the mixed liquor is pumped through the membrane.

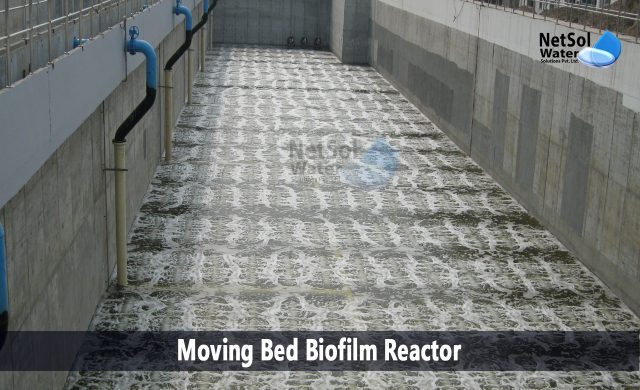

Moving Bed Biofilm Reactor (MBBR)

The moving bed biofilm reactor involves attaching biofilm to plastic carriers that move freely in the wastewater. The process is effective in removing organic matter and nitrogen from the wastewater.

In an MBBR, wastewater flows through a reactor tank containing the suspended biofilm carriers, which provide a surface for the growth of microorganisms. The aeration or mixing of the wastewater ensures that the biofilm carriers are constantly moving and in contact with the wastewater, which promotes the growth of the microorganisms on their surface.

As the wastewater flows through the reactor, the microorganisms on the biofilm carriers consume organic matter, converting it into biomass and other byproducts. The treated wastewater is then discharged, while the biofilm carriers are recycled back to the reactor tank.

Sewage Treatment Plant Manufacturers

Choosing the right sewage treatment plant manufacturer is essential to ensure the quality and efficiency of the plant. Here are some of the top sewage treatment plant manufacturers:

Netsol Water

Factors to consider when choosing a sewage treatment plant manufacturer

Urban STP plant

Urban STP Plant Top Most driving Conservative Sewage Treatment Plant Producer in India, begins fabricating other wastewater machines – Smaller Sewage Treatment Plant 5kld, 5kld bundled STP, Sewage Treatment Plants, and Zero Fluid Release Plants to shield ” Mother Earth Assets ” – Save Water Now.

Sewage Treatment Plants

We are the Sewage Treatment Plants (A Unit of Netsol Group & Research), having the best solution by STP Plant Manufacturer for waste and wastewater treatment. Since our establishment in the year 2012, we are one of the most trusted partners for waste management solutions. And integrated service providers of design, fabrication, installation, and maintenance services. With our years of expertise, we are the leading service provider for solutions, testing, monitoring, analysis, and recommended corrective actions in the field of waste and wastewater solutions.

We are the best solution provider for treating sludge and industrial effluent to save water as well as to save mother earth.

With our best innovation of Green Waste Converter Machine, we are daily converting thousands of kilo composite by treating Green and organic waste.

Factors to consider when choosing a sewage treatment plant manufacturer

Choosing a sewage treatment plant manufacturer is a decision that should be taken seriously. It is important to choose a manufacturer that provides quality products and services. Here are some factors to consider when choosing a sewage treatment plant manufacturer:

Experience: It is important to choose a manufacturer that has been in the industry for a significant amount of time. An experienced manufacturer is likely to provide better products and services.

Reputation: A good reputation is a clear indication of a manufacturer’s ability to deliver quality products and services. You can check the manufacturer’s website for customer reviews and testimonials.

Quality of products: The quality of products is a critical factor to consider. It is important to choose a manufacturer that provides high-quality products that meet your specific needs.

Customer service: Good customer service is important in any business. Choose a manufacturer that provides excellent customer service and is always available to answer your questions and address any concerns.

Price: The cost of the products and services is a significant factor to consider when choosing a manufacturer. It is important to choose a manufacturer that provides quality products and services at a reasonable price.

Why Choose Us?

We are one of the top manufacturers of sewage treatment plants in India, with years of experience and a track record of providing dependable and effective solutions to our customers. All sizes and capacities of sewage treatment plants can be designed, installed, and maintained by our team of professionals due to their technical skills and knowledge.

We offer a wide range of solutions, including:

- Traditional sewage treatment plants

- Packaged sewage treatment plants

- Membrane bioreactor (MBR) plants

- Sequential batch reactor (SBR) plants

- Extended aeration (EA) plants

- Moving bed biofilm reactor (MBBR) plants

All our solutions are designed to meet the highest quality standards and are backed by excellent after-sales service and technical support.

FAQs about sewage treatment plant manufacturers

What is a sewage treatment plant?

A sewage treatment plant is a facility that processes and treats wastewater to remove contaminants and produce clean water that can be safely discharged into the environment.

Why is it important to choose a reputable sewage treatment plant manufacturer?

Choosing a reputable sewage treatment plant manufacturer ensures that you receive high-quality products and services that meet your specific needs.

What are the different types of sewage treatment plants?

The different types of sewage treatment plants include conventional sewage treatment plants, package sewage treatment plants, and mobile sewage treatment plants.

How long do sewage treatment plants last?

Sewage treatment plants can last for up to 20-30 years, depending on the quality of the products and the maintenance practices.

What factors should I consider when choosing a sewage treatment plant?

The factors to consider when choosing a sewage treatment plant include the size and capacity of the plant, the quality of the products, the reputation of the manufacturer, and the cost of the products and services.