We are going to discuss some of the generally used sewage treatment plants in India. Every group or community produces liquid and solid waste. The water supplied becomes polluted after being used by colorful druggies. These druggies or the so- called sewage source could be institutes, diligence, domestic areas, marketable establishments, etc. undressed wastewater mustn’t be accumulated. They correspond of numerous perished mothers. It consists of putrefying organic matter.

However, they can produce an enormous quantum of foul- smelling feasts that can be dangerous to the terrain, If we keep these accoutrements for a while. also, it can also contain other poisonous composites that may be dangerous if expose to the terrain for a long time. thus, it’s essential to remove and clean the wastewater from its source.

Water is veritably precious; numerous people around the world aren’t getting enough water. So, due to the failure of water, exercise is an excellent option.

SOME TYPES OF SEWAGE TREATMENT Plants

There are different types of sewage treatment plants in India. The significant difference in them is the process or the way they treat the wastewater

- Rotating Slice System

It’s a natural treatment process for treating wastewater after primary treatment. They remove grains and other solids through a webbing process followed by a settling period. The RBC system involves allowing wastewater to come into contact with a natural medium. We do this in order to exclude pollutants in wastewater before the discharge of treated wastewater into the terrain. It consists of a series of nearly spaced, resembling discs mounted on a rotating shaft, supported just above the wastewater face. - Actuated Sludge Factory( ASF)

This is a traditional sanitarium wastewater treatment procedure. We treat wastewater in an open tank( aeration tank) in this process. We supply air either by a fixed/ floating face aerator or by an air cracker

to give oxygen to the aerobic microbes. roughly 12- 15 hours of hydraulic retention time is there for the treatment of wastewater. Microorganisms use oxygen in the air to convert organic matter into stabilized, low- energy composites similar as NO3, SO4, and CO3. also, they also synthesize new bacterial cells. - Suspended Media Pollutants( SMF)

These are designed to prize suspended solids from water and fluid systems. We separate these solids to a position of 5 microns using advanced endless media. When we withdraw these solids, the pressure drop through the media increases. The machine automatically-washes to tone-clean the media on the base of pressure drop or time. The SMF uses four layers of sludge media. These include crushed limestone, determinedness, anthracite, and refractory beach, which have advanced inflow rates and longer service life. These are descent- mounted in order to reduce conservation and space conditions. Some exemplifications of SMF are Allerton Drainage, Valance VES 1- 4, Clearwater Filter clear, Titan, Entec, Klargester Biotec( and Tailwind), Biodigester(pre-1997). - Submerged Aerated Sludge( SAF)

The submerged aerated sludge ( SAF) has a seal tank to explain the solids that are to get relieve out of the sludge rather of using backwashing. The factory has a depth of 1- 4 m of sludge media on which to grow biomass. The cracker

sends air to the bottom of the bed to give the biomass with oxygen to grease the oxidation process. The air sluice encourages the acceptable mixing of the effluent and the disturbance of any residual solids from the sludge medium. There are numerous SAF variants, and some are the combination system, the circle reactor system, the compartmentalized system,etc. - NON-ELECTRIC Sludge

Non-electric water cleansers are generally compact, making them a perfect choice when you need to travel regularly. In addition to power and cost considerations, these water cleansers are veritably easy to maintain. They’re veritably easy to install. However, which substantially have low situations of TDS, also these types of water cleansers are useful, If you get water from sources like external water force. They’re ideal in circumstances where there’s a deficit of energy or where you don’t want to use a lot of electricity. When you have filled the water in anon-electric water cleaner, it goes through these filtration stages on its own as a result of graveness. And, hence stores the clean water in the bottom of the water cleaner. - TRICKLING Sludge

A trickling sludge also called as the trickling biofilter, biofilter, natural sludge, and natural trickling sludge. It’s a fixed- bed, natural reactor operating under( substantially) aerobic conditions. Pre-installed wastewater is continuously tricked or scattered over the filter. However, the biofilm covering the sludge material degrades organic matter aerobically, If the water moves through the pores of the sludge. The benefit of all these styles is that they’re featherlight and that they exclude organic matter effectively. still, they’re high- tech and generally need professional construction and functional workers. Trickling pollutants are secondary treatment to the primary setting phase. - SEQUENCING BATCH REACTOR( SBR)

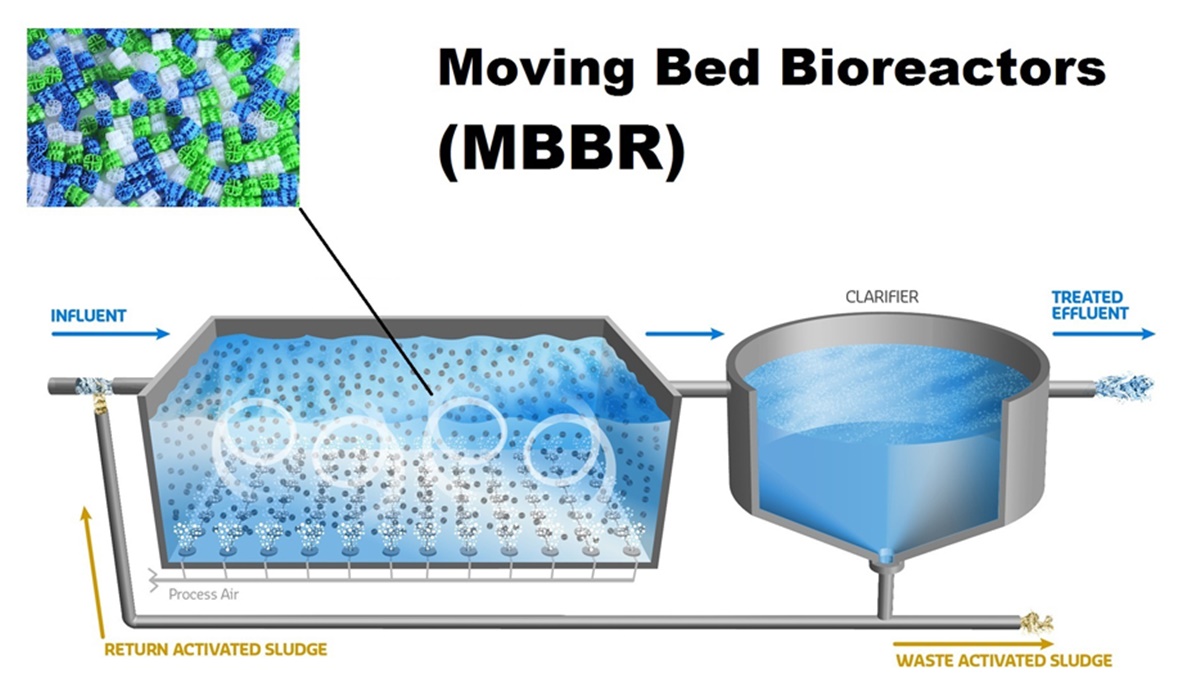

Sequencing batch reactors STP ( SBRs) or successional batch reactors are marketable wastewater treatment budgets. SBR reactors process wastewater, similar as sewage or anaerobic digester affair, or batch mechanical natural treatment shops. Oxygen is will be washing from wastewater to minimize biochemical oxygen demand( duck) and the demand for chemical oxygen( COD). It’s to make it suitable for discharge into semesters or for use on land. Although there are multiple SBR configurations, the primary medium is identical. Treatment consists of a five- stage cycle fill, reply, settle, draw and goof . SBRs are ideal for lower overflows since we get the size of each tank by the quantum of wastewater that gets to collect in the other tank during the treatment process. - MOVING BED BIOFILM REACTOR( MBBR)

With the Moving Bed Bioreactor STP ( MBBR), an provident option for wastewater treatment. It’s a good option only if the bulk of the impurity cargo has to get relieve of or if the applicable discharge regulations aren’t strict. The MBBR system consists of an actuated sludge aeration system, where the sludge is attained from recycled plastic carriers. These carriers have a large internal face for optimum commerce with water, air, and bacteria. For a number of different operations, the MBBR process may for producing the asked results. We achieve this on the base of the thickness of the wastewater and the discharge legislation. - MEMBRANE BIOREACTOR( MBR)

Membrane Bioreactor (MBR) is generally to describe wastewater treatment processes where a perm- picky membrane is combined with a natural process, specifically a suspended growth bioreactor. We consider MBR system to be a complete and completely integrating membrane unit with specific factors needed to enable the process to operate as asked . The advantages of MBR include a reduced footmark, generally 30- 50 percent lower than the similar traditional active sludge installation with secondary interpretations and tertiary media filtration.Conclusion

Sewage treatment plants in India have gained enormous fissionability. We all know the significance of pollution control and the saving of water. But, now technology has grown up, and numerous new ways came up to break this problem. Water recycling processes not only help to exercise water but also to keep the ecosystem safe and balanced. moment, we’ve a range of means and means to fix these problems. Water treatment processes not only help to conserve the water but also to keep the ecosystem safe and healthy. We at Netsol Water are having such a platoon of experts that can design one for your conditions and we’re confident to meet and over pass your demands. We’re delivering the same with new technology and quality that you can bear upon.

Do you have any queries regarding sewage treatment plants in India (STP Plant) or about the composition? also contact or email us. We’re happy to hear from you. Please browse our website to find further about us and our services. However, also please do check out our further blogs.