Top 3 Sewage Treatment Plant Manufacturers in Gurugram

Sewage treatment is a critical infrastructure requirement for any growing city. As Gurugram has rapidly urbanized over the past few decades, the demand for its sewage infrastructure has increased significantly. Proper sewage treatment is essential to maintaining public health standards and preventing environmental degradation. In recent years, the Gurugram Metropolitan Development Authority (GMDA) has focused on enhancing the city’s sewage treatment capacity. As part of this effort, GMDA has contracted with the top 3 sewage treatment plant manufacturers to set up new facilities as well as upgrade existing infrastructure.

What are Sewage Treatment Plants and Why Are They Needed in Gurugram?

Sewage treatment plants (STPs) are facilities that process sewage to remove contaminants and impurities before the treated wastewater is discharged back into the environment. Sewage contains organic matter, microorganisms, chemicals, heavy metals, and other pollutants that can be hazardous to public health and ecological systems if not properly treated.

STPs use a multi-stage treatment process that generally involves preliminary screening, primary sedimentation, secondary biological treatment, tertiary treatment, and final disinfection. This removes physical, chemical, and biological contaminants step-by-step to produce an environmentally safe discharge that can be reused or released into water bodies.

Gurugram produces a substantial amount of sewage daily, but its treatment capacity is currently lagging behind sewage generation. The gap between sewage generation and treatment results in untreated sewage being discharged into open drains and water bodies. This causes water pollution, diseases, and environmental damage. Expanding STP capacity is crucial for Gurugram to properly treat all the sewage it generates. Leading STP manufacturers are partnering with GMDA to establish new plants and augment existing infrastructure.

Top 3 STP Plant Manufacturers in Gurugram

- Netsol Water

Netsol Water is a pioneering STP manufacturer headquartered in Noida. It was established over 15 years ago and has emerged as one of India’s top companies specializing in sewage treatment solutions. Netsol has installed several hundred sewage treatment plants across India, treating a substantial volume of sewage daily.

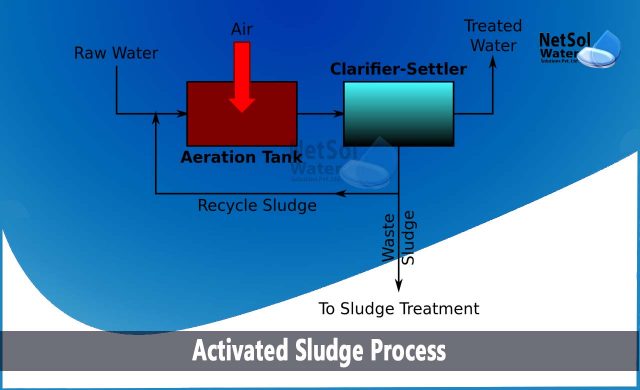

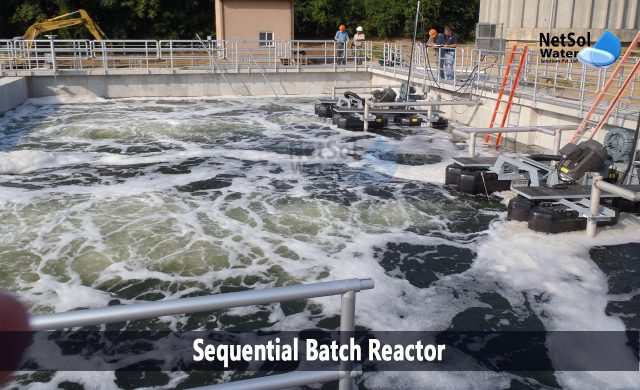

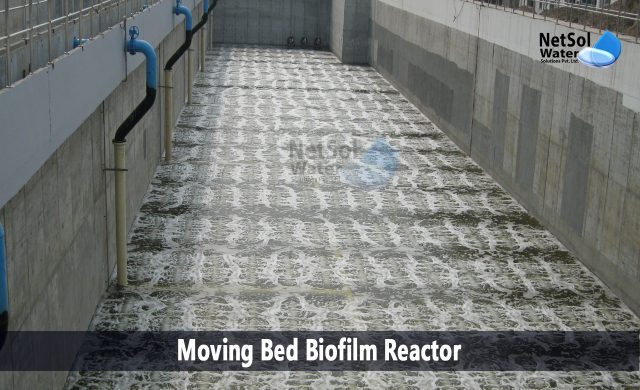

The company manufactures a range of innovative STP technologies tailored to different needs. Their offerings include conventional activated sludge process plants, sequencing batch reactor plants, moving bed biofilm reactor plants, oxidation ditch plants, and more. Netsol uses advanced automation to maximize plant efficiency and minimize maintenance requirements.

Netsol’s plants are designed to meet the highest effluent discharge standards in India. Their treatment process removes organics, solids, nutrients, and pathogens to deliver reusable or disposable-quality water. All plants come with remote monitoring and control capabilities.

As Gurugram’s leading STP plant manufacturer, Netsol has partnered with GMDA on multiple projects over the years. These include the Bandhwari wastewater treatment plant, the Dhanwapur STP, and the upgrade of the Behrampur STP among others. With its cutting-edge in-house R&D, proven technological expertise, and strong execution capabilities, Netsol is at the forefront of boosting Gurugram’s sewage treatment infrastructure.

- Sewage Treatment Plants

Sewage Treatment Plants is one of the world’s leading water technology multinationals. Sewage Treatment Plants has years of experience in municipal sewage treatment and serves many countries worldwide.

In India, Wabag provides turnkey solutions for sewage treatment plants based on conventional, advanced, and ultra-modern technologies. Their offerings include Activated Sludge Process, Sequential Batch Reactor, Tertiary Treatment, Moving Bed Biofilm Reactor and Membrane Bio-Reactor plants among other technologies.

Sewage Treatment Plants deploy automation systems for plant automation. This enables remote monitoring, control, and optimized performance. Wabag’s advanced solutions ensure maximum operational efficiency and enable the reuse of treated sewage.

- Urban STP Plant

Urban STP Plant is one of India’s leading industrial water and wastewater treatment companies. The firm has decades of experience in municipal sewage treatment solutions.

The Urban STP Plant offers a comprehensive portfolio of sewage treatment technologies, such as conventional activated sludge processes, biological nutrient removal, sequencing batch reactors, moving bed biofilm reactors, membrane bioreactors, and more. It provides customized solutions depending on client needs and site-specific conditions.

Urban STP Plant designs STPs with advanced automation for intelligent control and remote monitoring. Its plants meet all Central Pollution Control Board (CPCB) effluent discharge norms. The company also undertakes operations and maintenance of STPs.

Conclusion

Expanding sewage treatment capacity is a high priority for Gurugram. Leading Indian STP plant manufacturers like Netsol Water, Sewage Treatment Plants and Urban STP Plants have partnered with GMDA on strategic projects over the years to enhance the city’s sewage treatment infrastructure. Their advanced solutions, utilizing technologies like SBR, MBBR, and MBR, will help Gurugram treat all the sewage it generates. Managing sewage effectively will improve public health outcomes, prevent environmental damage, and enable the reuse of treated water. GMDA’s collaboration with top STP manufacturers will augment Gurugram’s capabilities and support its future growth aspirations.

Do you need advice or assistance in selecting the best water and wastewater treatment unit? We have solutions for all your problems!

Let us know your problem, and our experts will make sure that it goes away.

For assistance or related queries,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com