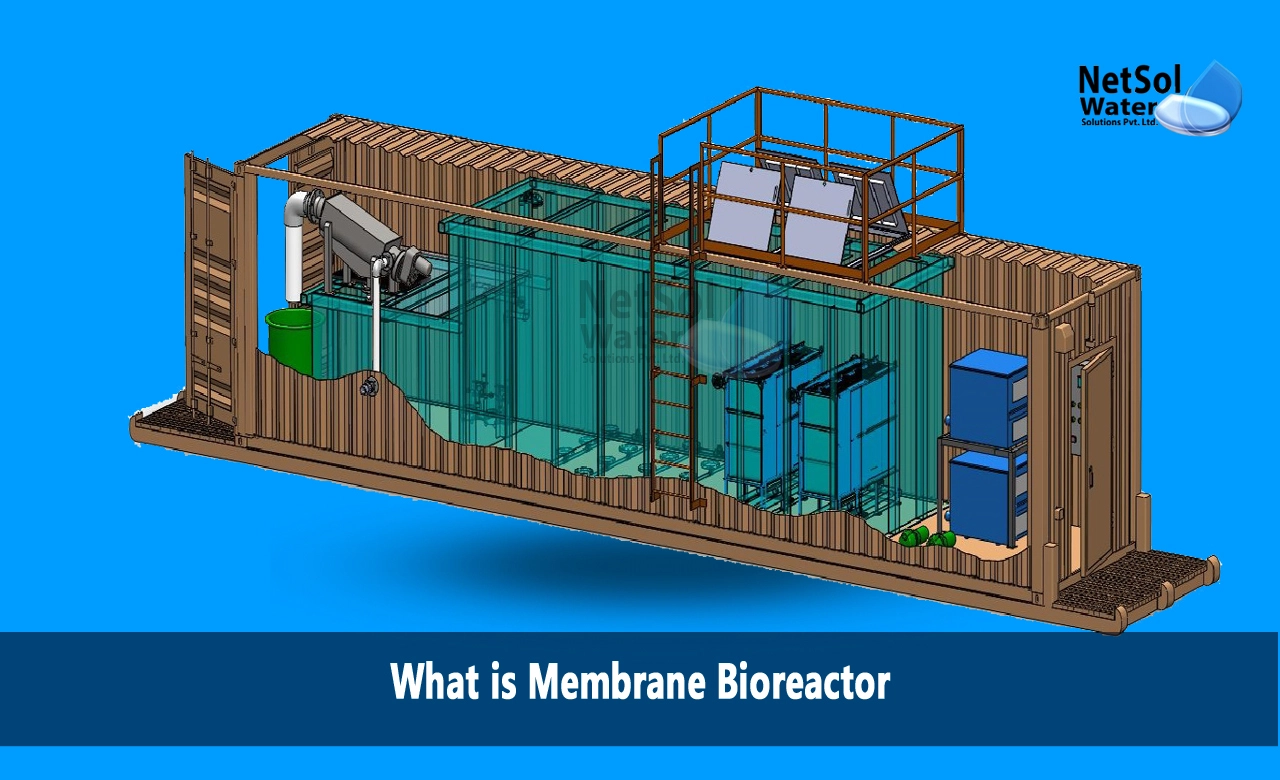

What is Membrane Bioreactor?

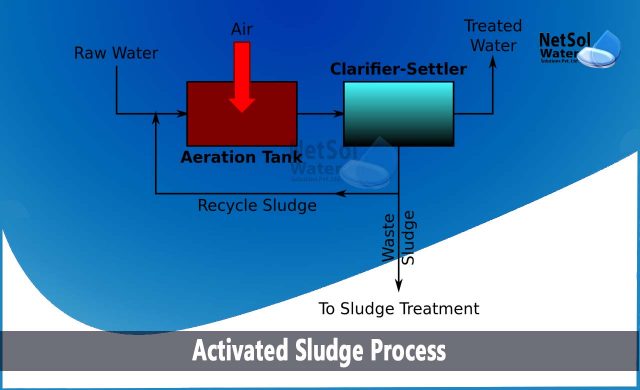

Membrane bioreactors are a technology that is used in wastewater treatment. The MBR combines membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. These technologies are now widely used for municipal and industrial wastewater treatment. The two basic membrane bioreactors are the submerged membrane bioreactor and side-stream membrane bioreactor. In a submerged membrane bioreactor, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor.

Components of Membrane Bioreactor

-

Membrane Modules

MBR uses ultrafiltration or microfiltration membranes that act as physical barriers to separate suspended solids, microorganisms and pathogens from wastewater.

-

Biological Reactor

This component provides microorganisms that degrade organic pollutants present in wastewater through aerobic or anaerobic processes.

-

Aeration System

Aeration is necessary to maintain optimal microbial growth and activity within the biological reactor. It ensures sufficient oxygen supply for aerobic degradation of organic matter.

How do Membrane Bioreactors work?

Membrane bioreactors operate through a combination of physical filtration and biological treatment processes. Wastewater passes through the membrane modules where suspended solids and microorganisms are retained while the treated water filters through the membrane. Concurrently microorganisms in the biological reactor break down organic contaminants, resulting in treated effluent of superior quality.

Advantages of Membrane Bioreactors

Membrane Bioreactor offer several advantages including

Improved Effluent Quality: MBRs produce treated water with low levels of suspended solids, pathogens, and contaminants, meeting stringent regulatory standards.

Space Efficiency: Their compact design and high treatment efficiency make MBRs suitable for installations in densely populated urban areas or industries with limited space.

Flexibility in Design: Membrane Bioreactor systems can be customized to accommodate fluctuations in wastewater characteristics and treatment requirements.

Applications of Membrane Bioreactors

Membrane bioreactor have various applications in both municipal and industrial wastewater treatment plants like

Municipal Wastewater Treatment: Membrane Bioreactor Systems are increasingly adopted by municipalities for treating domestic sewage and producing reusable water for non-potable purposes.

Industrial Wastewater Treatment: Various industries including like food and beverage, pharmaceuticals, and electronics, utilize MBR technology for treating complex industrial effluents.

Challenges and Limitations of Membrane Bioreactors

Membrane Fouling: Accumulation of solids and biological matter on the membrane surface can lead to reduced permeability and increased energy consumption.

High Capital and Operating Costs: The initial investment and ongoing operational expenses associated with MBR systems can be significantly higher than conventional treatment methods.

Recent Developments in Membrane Bioreactor Technology

Continuous research and development efforts have led to innovations aimed at overcoming MBR limitations, including:

Enhanced Membrane Materials: Novel membrane materials with improved fouling resistance and durability contribute to a longer membrane lifespan and reduced maintenance requirements.

Energy-Saving Innovations: Integration of energy recovery systems, such as membrane aeration control and membrane cleaning optimization, helps minimize energy consumption and operating costs.

Future Outlook of Membrane Bioreactors

The future of MBR technology looks promising, with ongoing advancements expected to further enhance their performance and applicability. Anticipated developments include:

Potential Advancements: Emerging technologies like membrane bioreactor hybrid systems and membrane distillation hold promise for addressing current MBR limitations and expanding their scope of applications.

Market Growth Projections: With increasing environmental regulations and growing water scarcity concerns worldwide, the global market for membrane bioreactors is projected to witness steady growth in the coming years.

Conclusion

Membrane bioreactors represent a sustainable and efficient solution for wastewater treatment, offering high-quality effluent, space-saving design, and versatility in application. Despite facing challenges such as membrane fouling and high costs, ongoing research and innovation continue to drive improvements in MBR technology, ensuring its continued relevance in addressing water management challenges globally.

FAQs

Are membrane bioreactors suitable for treating industrial wastewater?

Yes, membrane bioreactors are widely used in various industries for treating complex industrial effluents, thanks to their high treatment efficiency and versatility.

How do membrane bioreactors compare to conventional wastewater treatment plants?

Membrane bioreactors offer superior effluent quality and space-saving design compared to conventional treatment plants. However, they tend to have higher capital and operating costs.

What measures can be taken to prevent membrane fouling in MBR systems?

Strategies for mitigating membrane fouling include regular membrane cleaning, optimization of operating conditions, and the use of advanced membrane materials with fouling-resistant properties.

Are membrane bioreactors suitable for decentralized wastewater treatment?

Yes, membrane bioreactors are well-suited for decentralized applications due to their compact footprint and high treatment efficiency, making them ideal for small communities or remote areas.

What role do membrane bioreactors play in water reuse initiatives?

Membrane bioreactors play a crucial role in water reuse by producing treated effluent of sufficiently high quality for non-potable applications such as irrigation, industrial processes, and toilet flushing.

To learn about the best sewage treatment plant manufacturers in Delhi, Click on the link