The Actuated Sludge (AS) process is as of now the most broadly utilized biological wastewater treatment process in the world.

Since its conception in the late nineteenth hundred years and resulting improvement into a full-scale process in 1913 by Arden and Lockett at the Davyhulme sewage treatment works in Manchester, the essential cycle has been broadly taken on and further created providing it with an exceptional adaptability of activity.

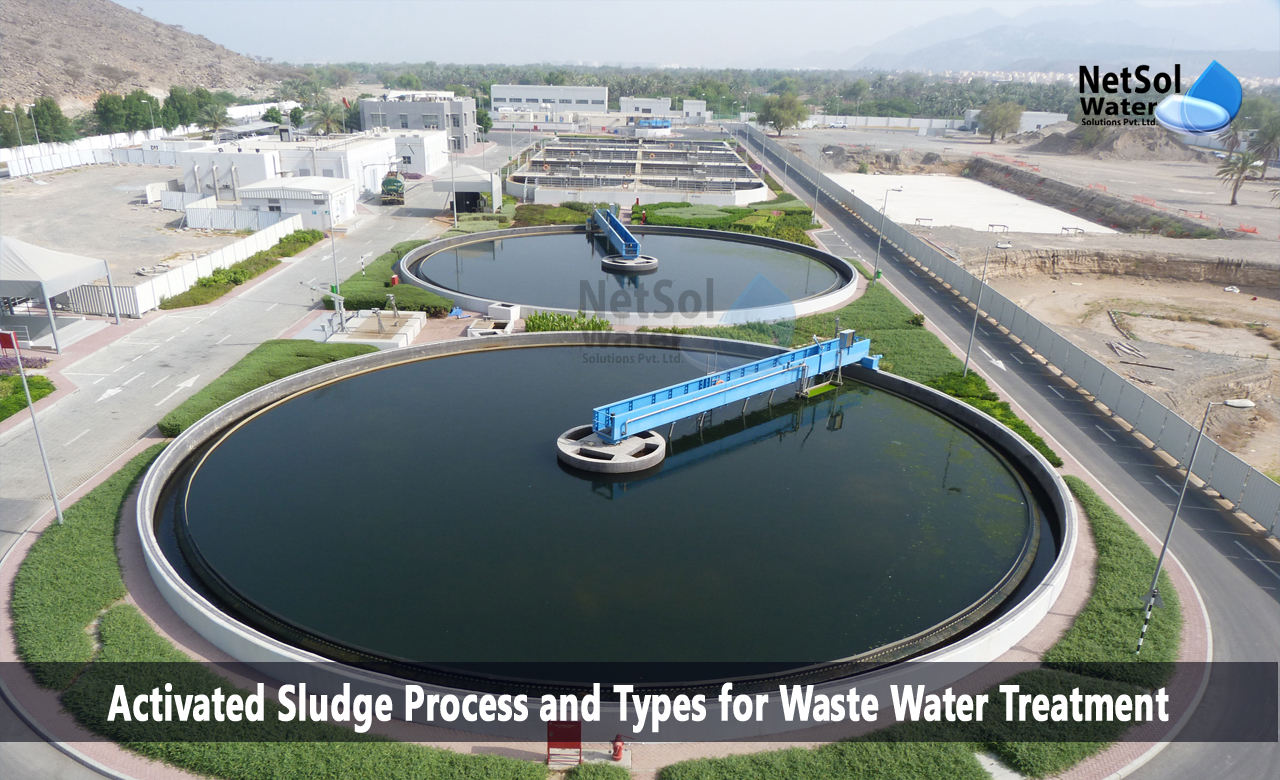

Activated Sludge Process and Types for Wastewater Treatment: Everything You Need to Know

In the Activated Sludge Process (ASP) for wastewater treatment, microorganisms, including microbes, bacteria, fungi, and protozoa, are utilized to accelerate the decomposition of organic matter requiring oxygen for treatment.

In this Activated Sludge Process (ASP), microorganisms are totally blended in with organics under conditions that stimulate their growth, and waste materials are eliminated. As the microorganisms grow and are blended by the agitation of the air, the individual microorganisms cluster and flocculate together to shape a mass of organisms called activated sludge.

Activated Sludge Meaning

The Activated Sludge name and meaning start from the process it includes the development of an initiated mass of microorganisms equipped for vigorously settling the organic content of wastewater, subsequently, it is “activated”.

Conventional Activated Sludge System in Water & Sewage Treatment

An ordinary activated sludge system for sewage treatment incorporates:

- The aeration tank where the biological responses occur;

- An aeration source that gives oxygen, mixing and blending;

- A tank, known as the clarifier, where solids settle and are isolated from treated wastewater;

- A collecting means for the solids either to return to the aeration tank, returned activated sludge, or eliminate from the process (waste-activated sludge).

A total complete system for sewage treatment incorporates chlorinators, holding tanks, pumps, and a control system that screens the treatment effectiveness.

Activated Sludge Plant Components and Design

The Activated Sludge Plant (ASP) comprises a balance bowl, PST, an aeration tank, an secondary settling tank (SST), and a sludge reuse line.

Feed wastewater is homogenized in an equalization basin to reduce varieties in the feed, which might cause process upsets of the microorganisms and reduce water treatment effectiveness.

In the aeration tank, the aerobic bacterial population is kept up in suspension in the blended liquor and oxygen, as well as supplements are given. Oxygen is provided either by mechanical or diffused aeration, which additionally helps with keeping the microbial population in suspension. The blended liquor is consistently released from the aeration tank into a secondary clarifier in a wastewater and sewage treatment system.

Efficient & Effective Activated Sludge Process Design

The Activated Sludge process offers proficient and effective removal of BOD, COD, and supplements when designed professionally and worked appropriately. The actual process has flexibility and various modifications can be custom-made to meet specific requirements (for example for nitrogen removal).

Activated sludge is a complex mix of microbiology and biochemistry including a wide range of kinds of microorganisms. In the Activated Sludge Plant (ASP) microbes, bacteria secrete sticky substances that coat the minute particles conveyed in sewage. The particles remain together to shape flocs of a gel-like material, making help on, and in which, organisms exist. This is the brown-colored activated sludge.

The activated sludge is circulated to dissolve oxygen which permits the organic matter (BOD) to be used by the microbes. The organic matter, or food, adheres to the activated sludge. The oxygen dissolved in the water allows the microbes to utilize the food (BOD) and furthermore to change the ammonia to nitrate. The activated sludge tank should be big enough to allow sufficient contact time (retention time) between the sewage and the activated sludge for every one of the chemical changes to take place.

Return Activated Sludge (RAS)

The settled biomass, called Return Activated Sludge (RAS), is then returned to the start of the aeration process where it will retain new sewage to begin the interaction in the process again. This enables the process to operate as a continuous cycle.

At the point when the Activated Sludge reaches the finish of the process it is as yet an exceptionally active biomass, however, is currently blended in with purified effluent. It is moved to Settlement Tanks (Secondary Clarifiers) to permit separation from the purified effluent which might be released to the river or to some type of tertiary treatment.

Surplus Activated Sludge (SAS)

The Surplus Activated Sludge (SAS) is wasted by constantly pulling out a portion of the RAS for sludge disposal.

As a matter of fact, as the RAS mixing in with the new sewage will produce a slow development in the activated sludge present it is necessary to waste a certain quantity each day.

Activated Sludge Types

There are nine types of activated sludge processes:

- Tapered Aeration

- Step Aeration

- High-Rate Treatment or Modified Aeration

- Two Stage Aeration

- Activated Aeration

- Reaeration

- Contact Stabilization

- Complete Mix

- Extended Aeration Method

1- Tapered Aeration or Controlled Aeration

Tapered aeration is also called controlled aeration. Assuming examples are gathered at different places in the aeration units, it will be observed that the BOD of the mixing liquor isn’t uniform all through; it is most extremely close to the channel and least close to the power source. Because of this explanation on the off chance that the diffused air is applied at a uniform rate, it can’t be used as expected.

2- Step Aeration

Assuming that the sewage is added to the returned sludge at multiple focuses along the aeration channel, the load coming on the returned sludge is changing. In the past article, it has been expressed that the BOD of the mixed liquor is different at various places.

3- High-Rate Treatment or Modified Aeration

In the high-rate treatment (or Modified Areation) technique, less quantity of returned sludge is used, consequently, it is called high-rate treatment. In high-rate treatment shorter detention period (2 hours), a lesser amount of packed air, and a small amount of returned sludge are used.

4- Two-Stage Aeration

In two-stage aeration, the sewage is permitted to flow in a couple of aeration and sedimentation units. The activated sludge is either returned for the purpose of cultivating or excess sludge from the second stage is again sent off the first cycle from which both of it and the excess of the first stage are mixed with influent.

5- Activated Aeration

It is a combination of two tapered activated sludge plants equal involving similarly settled sewage as influent. The inordinate activated sludge of one plant is used as seed for another plant, which is called activated aeration.

6- Reaeration

In this technique, the minimum aeration of sewage is finished in the wake of adding returned sludge to it. To fulfill the BOD reaeration of returned sludge is finished prior to mixing it in with the sewage. On the off chance that the reaeration is finished in advance of the trickling filter, it is called bio aeration.

7- Contact Stabilization

The contact adjustment is also called biosorption. In this process, sewage might be dealt with either after primary settling or without primary settling. The sewage is aerated through alongside return sludge for a comparatively short period of 0.5 to 1.5 hrs. when the sludge absorbs the organic matter in the sewage.

The mixed liquor is then settled in a secondary settling tank. The return part of the sludge removed from the settling tank is reaerated in a different sludge reaeration tank for a time of 3-6 hrs. before it is taken care of once more into the contact aeration tank. During the reaeration of the sludge, the absorbed organics are settled restoring the adsorptive capacity of the sludge.

8- Complete Mix

The complete mix-activated sludge process utilizes a totally mixed flow system. In a rectangular tank, complete mixing is achieved by distributing the sewage and the return sludge consistently along one side of the tank and withdrawing the aerated sewage, consistently along the opposite side. In the case of a round or square tank, complete mixing is achieved by a mechanical aerator with adequate mixing capacity installed at the center of the tank.

9- Extended Aeration Method

The flow plan of the extended aeration process and its mixing system are like that of the total mixing process. The oxidation ditch likewise adjusts to the drawn-out aeration guideline and depends on aeration through the mixing of liquor in an endless ditch. Primary settling is discarded in the drawn-out extended aeration method, however, condemnation is often provided for screenings.