How Much TDS in Water is Safe for Animals?

Animals rely on clean water to stay healthy and active. In regions known for dry climates or hard water sources we often see higher mineral content in water. That mineral content shows up as Total Dissolved Solids or TDS. Farmers and pet owners must know how much TDS in water remains safe for animals. High TDS levels can harm digestion, disturb fluid balance, and affect growth. Low TDS levels may lack essential minerals that animals need.

TDS: Why It Matters to Animals

Water carries minerals and salts that rise as Total Dissolved Solids. In low amounts these minerals support bone strength and nerve function. In large amounts they hinder hydration and performance. Let us have a look on some key aspects of TDS and its role for animal health.

What Total Dissolved Solids Include

When water flows through soil and rock it picks up small particles. Those particles join in solution as positive and negative ions. Common ions include calcium and magnesium. They give water hardness. They also include sodium and chloride. Excess salts strain kidney function in animals. In contrast trace minerals help maintain fluid balance. Understanding that balance helps set the safe TDS for animals.

How High TDS Affects Animal Health

High mineral load adds pressure on the digestive tract. It forces animals to use more water to flush out salts. That leads to dehydration even when water intake seems high. It also causes loose stool in livestock and pets. In birds it can impact egg production and shell quality. Those effects can harm growth rates and product yield in farm settings. Recognizing those risks drives the need to keep TDS within the safe range.

Determining Safe TDS Levels for Various Animal Types

Different species tolerate minerals at different rates. Cattle handle higher hardness than poultry. Sheep need moderate levels to avoid urinary stones. Let us have a look on some examples that show safe TDS for animals by type.

Cattle and Large Ruminants

Cattle can drink water with up to 3 000 mg/L of TDS without severe harm. They adapt by drinking more water. But sustained exposure above 2 000 mg/L can slow weight gain. It can also reduce milk yield in dairy herds. Netsol Water designs testing kits that measure mineral content on site. Those kits help farmers keep levels below risk thresholds.

Poultry and Small Livestock

Chickens and turkeys perform best with TDS below 1 500 mg/L. Above that level they drink less water. They show lower egg production and slower growth. In goats and sheep the limit stands near 2 000 mg/L. Exceeding that level raises risk of kidney stones in goats. Regular testing helps owners manage mineral intake.

Strategies to Manage and Reduce TDS in Animal Water Supplies

Once you know your water’s TDS you can choose a treatment method. Netsol Water offers solutions that match farm scale and budget. Let us have a look on some common methods and how they apply in the field.

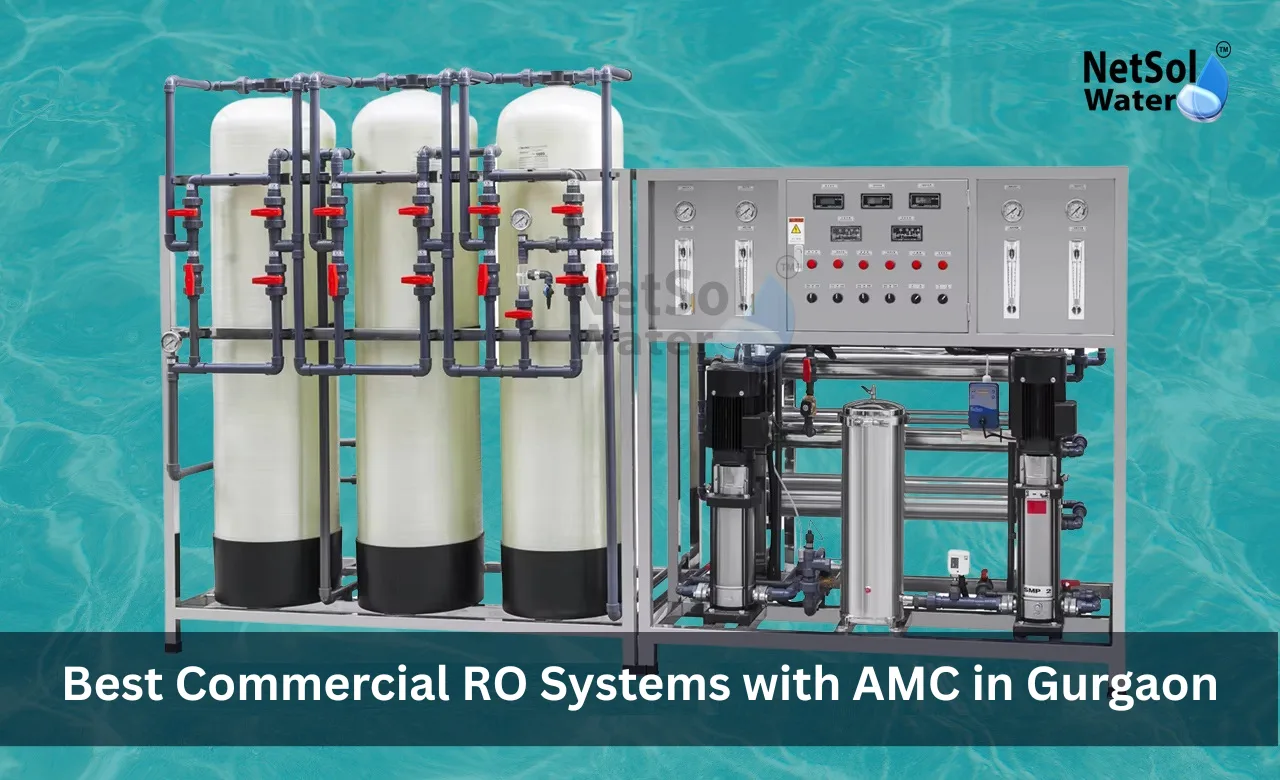

Reverse Osmosis Plants

RO forces water through a semipermeable membrane. It strips out up to 99 percent of dissolved solids. Farmers use RO plants at wellheads or barn taps. RO plants require periodic cleaning and power. Netsol Water customizes RO modules for remote locations. Those modules run on solar power when grid access remains unreliable.

Ion Exchange and Softening

Ion exchange swaps harmful sodium and chloride for sodium-free minerals. It works best when TDS sits below 3 000 mg/L. Water passes through a resin bed that holds unwanted ions. The system then regenerates resin with a salt solution. Netsol Water installs softeners that handle large flow rates.

Conclusion

Understanding safe TDS for animals helps you protect health and performance. You can test water with portable meters and lab kits. Then treat water with RO plants or ion exchange units as needed. Contact Netsol Water today for advice on safe TDS for animals and to arrange a consultation. Let us help you give your animals the clean water they deserve.

Phone: +91-965-060-8473

Email: enquiry@netsolwater.com