3 Best Industrial RO Plant Manufacturers in Ghaziabad

Industrial growth in Ghaziabad keeps on escalating at a fast pace, accompanied by an increase in the demand for quality water treatment solutions. There are industries here which require clean water not only for safety and regulation purposes but also to ensure the quality of their products as well as the machinery. Therefore, selection of the right industrial RO plant manufacturer becomes extremely crucial in such a situation.

Here are the 3 best industrial RO plant manufacturers in Ghaziabad, according to performance, reliability, and customer satisfaction.

3 Best Industrial RO Plant Manufacturers in Ghaziabad

1. Netsol Water

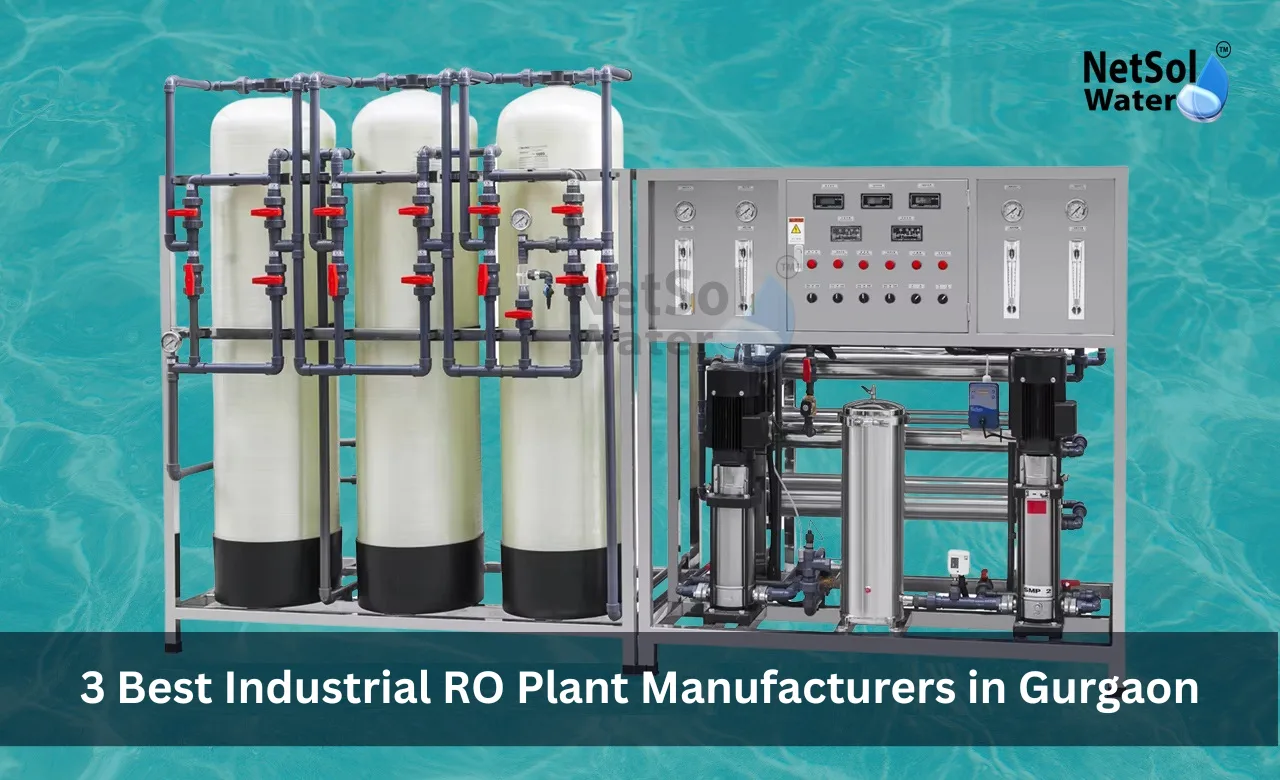

We at Netsol Water proudly rank among the 3 best industrial RO plant manufacturers in Ghaziabad. With years of practical experience, we have established a strong reputation for providing effective and cost-friendly water treatment plants. Our industrial RO plants are formulated to address the particular requirements of various industries in Ghaziabad.

What Makes Us Stand Out?

One of the major reasons why companies place their faith in us is the vast array of capacities we provide. Our industrial RO units vary from 100 LPH (litres per hour) to 10,000 LPH and more, based on what a factory requires. Whether a customer operates a small workshop or a big processing unit, we have a unit that suits them perfectly.

We provide services to a range of industries including:

- Textile and garment units requiring clean water for washing and dyeing.

- Pharmaceutical industry where the purity of water is essential to production.

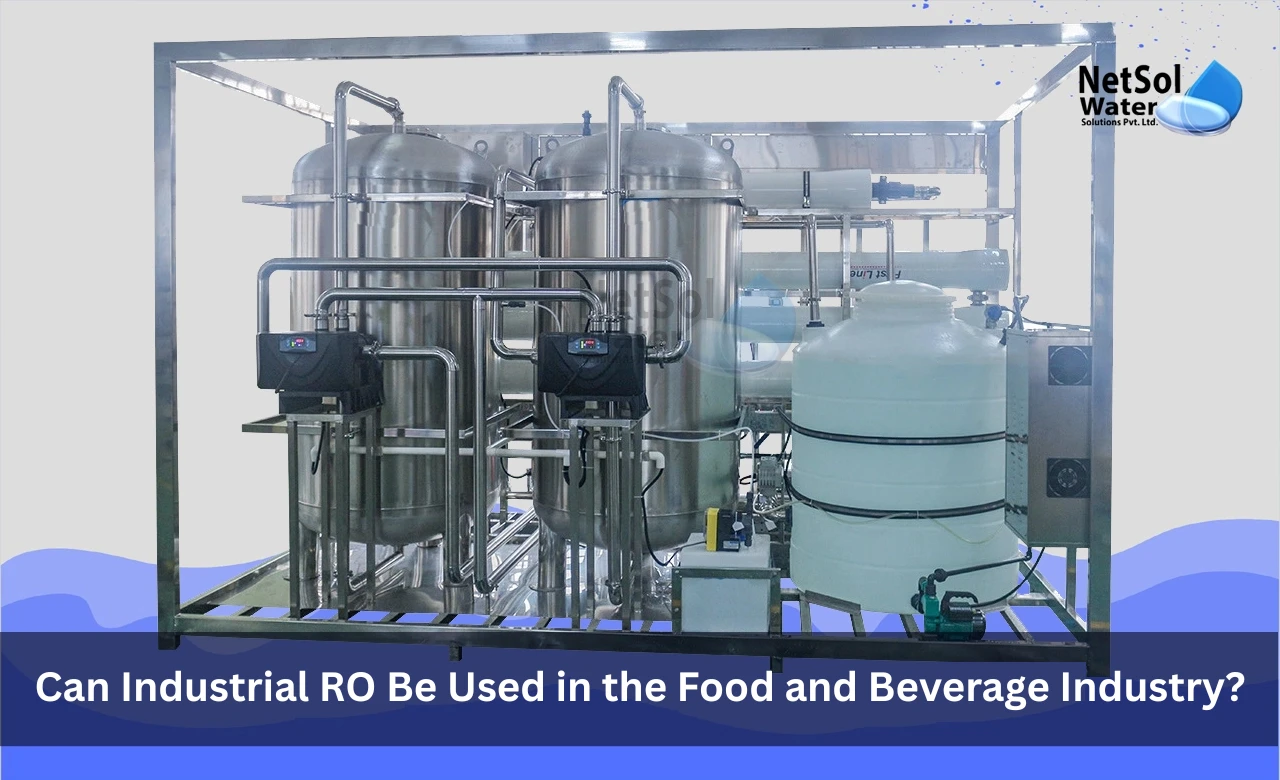

- Food and beverage plants that utilize RO water in preparation and cleaning.

- Chemical and metal industries requiring water for cooling, mixing, and cleaning.

Our plants are constructed with the best-grade components and have advanced membranes, intelligent control panels, and energy-efficient motors. We also offer complete post-installation support, including maintenance, training, and system upgradations. It’s this commitment that makes us the go-to option throughout Ghaziabad.

2. AquaSure Technologies

AquaSure Technologies is another reputed company in the industrial RO plant market. AquaSure offers a comprehensive variety of reverse osmosis plants to suit diverse industrial requirements. With good delivery time and reasonable prices, AquaSure aims to offer reliable systems supported by standard functions and reasonable after-sales service.

They have installed a number of units in Ghaziabad industrial areas, particularly in manufacturing units that handle paint, food packaging, and surface treatment. They provide their systems with stainless steel frameworks, multi-stage filtration, and available automation options.

3. Clear Aqua Systems

Clear Aqua Systems is also one of the 3 best industrial RO plant manufacturers in Ghaziabad, known for their reliable quality and good customer base. They deal in both regular and bespoke RO plants, primarily to small-to-medium factories.

The focus of the company is on cost-effective systems that are low-maintenance. While their products might not be as advanced as others, they are valued by local industries for being reliable and service-oriented. Industries they typically serve are furniture manufacturing, electronics, and paper processing.

How Industrial RO Plants Help Ghaziabad Industries

Industrial RO plants are not a luxury anymore but a requirement for expanding businesses in Ghaziabad. Here’s how they contribute to the local industrial economy:

Enhance Product Quality: Pure water is dependent on various industries such as pharmaceuticals and food. RO plants make sure that the water supplied is free from toxic minerals and contaminants, which translates to higher quality products.

Save Machinery: Hard or contaminated water can harm machinery and shorten its life. Utilization of RO-treated water avoids scale deposit and corrosion, maintaining machinery in a sound working state.

Save Costs in the Long Run: Although the installation involves investment initially, industrial RO plants save money on water charges, machine maintenance, and stoppages. Treated water can be reused in different stages of manufacture often.

Meet Environmental Standards: Government laws are getting tougher regarding wastewater and water consumption. RO plants assist businesses in being compliant by lowering contaminants in discharged water.

Aid Sustainability: Most Ghaziabad industries are now searching for ways to decrease their ecological footprint. Industrial RO plants aid these objectives by lowering water usage and encouraging reuse.

Conclusion

Water is the lifeblood of industrial operations, and if not treated properly, it can become a liability. It is for this reason that selecting the appropriate RO plant manufacturer is important. Netsol Water, AquaSure Technologies, and Clear Aqua Systems are the 3 best industrial RO plant manufacturers in Ghaziabad and have demonstrated their ability by providing quality, long-lasting, and efficient systems.

Of these, we at Netsol Water persist in dominating through cutting-edge technology, extensive capacity range, and customer-oriented services. With us, industries not only receive a trusted RO plant but also a long-term partner who believes in long-term success. If you’re operating or about to operate an industrial facility in Ghaziabad, investing in the correct RO plant is one of the wisest decisions you can make.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473

Or write us at enquiry@netsolwater.com