Package sewage treatment plant are used in rural areas, trace rest stops and caravan premises where population to be served ranges from 10 – 100 people or so. One type of system that combines secondary treatment and agreement is the cyclic actuated sludge. generally, actuated sludge is mixed with raw incoming sewage, and aerated.

One type of system that combines secondary treatment and agreement is the cyclic actuated sludge. generally, actuated sludge is mixed with raw incoming sewage, and aerated. The settled sludge is run off and re-aerated before a proportion is returned to the head works. The disadvantage of the process is that it requires a precise control of timing, mixing and aeration. This perfection is generally achieved with computer controls linked to detectors. Such a complex, fragile system is unsuited to places where controls may be unreliable, inadequately maintained, or where the power force may be intermittent. SBR plants are now being stationed in numerous corridor of the world.

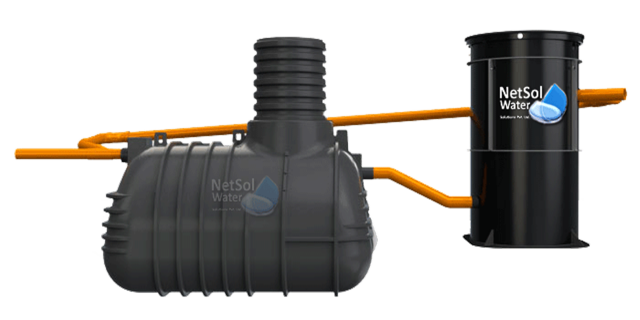

Extended aeration package STP plant (Package Type STP) use separate basins for aeration and settling, and are kindly larger than SBR plants with reduced timing perceptivity.

utmost sewage treatment treatment plants are anteceded by some type of pre-treatment device which will remove some untreatable matter and help it from entering the waste inflow( plastics, rags, jewels, etc.). The three types of pre-treatment bias are trash traps, bar defenses, and comminutors. In addition, kitchen drains from food service operations should be discharged through a duly sized grease trap. Flow equalization may also be needed in shops subordinated to extensively shifting hydraulic ladings. A inflow equalization tank allows the overflows coming to the factory to be held and pumped at a invariant rate to the factory.

The aeration chamber is the crucial part of the secondary treatment factory where 90 of the treatment occurs. This process operates under the following proposition Waste in domestic wastewater is generally organic( biodegradable), which means that aerobic microorganisms in the presence of oxygen can use the organic material as their food source.

In nature, if the waste were discharged undressed to a sluice, the bacteria in the sluice would putrefy the sewage and deplete dissolved oxygen situations to a point which could kill all submarine life in the sluice. analogous to nature, in an extended aeration treatment system, air( 20 oxygen) is introduced by boasters and bacteria are grown to feed on incoming sewage from your business or lodging. Bacteria in the aeration tank putrefy the sewage to form a suspended sludge. The liquid in the aeration chamber, called mixed liquor, will have the thickness of thin milk shake and a brown color analogous to that of coffee with cream. still, it should be noted that the color will vary from system to system depending on the types of wastes.

A settling chamber( purifier) is placed after the aeration chamber to allow the microorganisms that are grown in the aeration chamber to settle by graveness, forming sludge on the bottom of the purifier. utmost of the microorganisms settle to the bottom of the settling chamber where they’re also pumped back to the head of the aeration chamber. The microorganisms also begin the cycle of feeding on incoming organics in the wastewater. This material is known as return actuated sludge( RAS). The clear liquid at the top of the settling chamber will also generally flow to a dosing pump station/ slow face beach sludge or polishing pond where farther treatment is handed.

Typical MBBR grounded packaged Sewage Treatment Plant cut out section

There are also alternate designs with SAFF & MBBR technology for reduced bottom print. The treated discharge is also disinfected with chlorine, and the chlorine is removed by a Dichlorination unit. Some installations are now replacing chlorination/ dichlorination units with ultraviolet forms of disinfection. Final discharge is typically to a sluice with sufficient dilution to safely assimilate the remaining 5 of the adulterants without measurable detriment to the terrain.

Package sewage treatment plant Advantages

–Pre-assembled, descent- mounted and plant- tested packaged systems have lower conditions for installation and reduced onsite construction costs.

– Compact designs for easy integration into being installations

– Completed engineering packages with quick delivery

– Comprehensive cleaning capabilities for peak systems performance

– Simple operation and conservation requires minimum driver supervision.

We at Netsol Water is One of the leading sewage treatment plant manufacturer, who is into consulting, manufacturing, designing, commissioning of STP, ETP and Water Treatment Plants. Call Us 24×7 @9650608473 for any enquiry or product related query.